Aug . 12, 2024 14:36 Back to list

Comparison of Dust Seals and Oil Seals in Mechanical Applications and Their Performance Differences

Dust Seal vs. Oil Seal Understanding the Differences and Applications

When it comes to machinery and mechanical components, seals play a crucial role in maintaining efficiency and longevity. Among the various types of seals, dust seals and oil seals are commonly used, yet they serve different purposes and are designed for specific applications. Understanding the differences between these two types of seals can help in selecting the right seal for various engineering and industrial applications.

Dust Seals

Dust seals, often referred to as dirt seals or grease seals, are primarily designed to keep dust, dirt, and other contaminants out of machinery and mechanical systems. They are typically used in environments where exposure to external elements is prevalent. Dust seals are commonly found in applications such as automotive wheels, construction equipment, and agricultural machinery, where the risk of contamination is high.

Typically made from materials like rubber, silicone, or neoprene, dust seals form a barrier that prevents contaminants from entering critical parts of machinery. This is particularly important in rotating equipment, where dust can lead to increased wear and tear on moving parts. By keeping contaminants out, dust seals help maintain the integrity and performance of the equipment, ultimately prolonging its lifespan.

Oil Seals

On the other hand, oil seals, also known as shaft seals or lip seals, are designed to retain lubricants, such as oil or grease, within a component while preventing the leakage of fluids. Oil seals are used in applications where lubrication is essential for the smooth operation of machinery and equipment. They are commonly found in engines, pumps, gearboxes, and hydraulic systems.

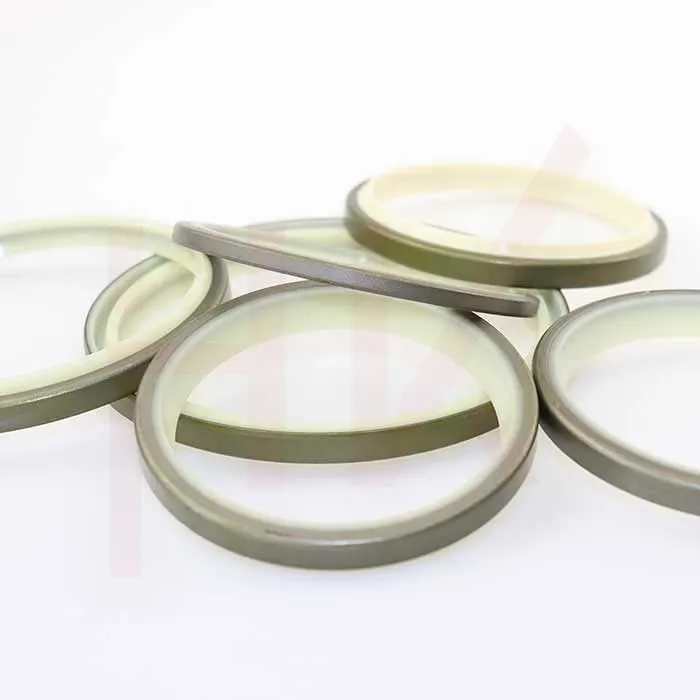

dust seal vs oil seal

Oil seals typically feature a flexible lip that contacts the shaft to create a tight seal. This design allows oil seals to withstand higher pressures and temperatures compared to dust seals. They are often made from various materials, including elastomers, which are resistant to oil and other chemicals. The primary function of an oil seal is to maintain a coupling’s lubrication system while preventing leaks, thereby ensuring optimal performance and efficiency of the machinery.

Key Differences

The primary difference between dust seals and oil seals lies in their intended purpose. While dust seals are focused on preventing external contaminants from entering a system, oil seals focus on retaining lubricants and preventing leakage of fluids. This fundamental difference reflects their respective designs—a dust seal prioritizes dust and dirt resistance, whereas an oil seal prioritizes fluid retention and sealing performance.

Another aspect to consider is the environment in which each seal operates. Dust seals are commonly employed in dirty or dusty environments, where exposure to non-lubricating contaminants is high, while oil seals are typically found in cleaner environments where maintaining lubricant integrity is essential.

Conclusion

Choosing the right seal for a specific application is vital for ensuring the reliability and efficiency of machinery. Understanding the differences between dust seals and oil seals is essential for engineers and technicians involved in system design and maintenance. By selecting the appropriate seal based on environmental conditions and operational requirements, one can enhance machine performance, reduce maintenance costs, and prolong the life of the equipment. Whether it’s protecting a system from dust or retaining essential lubricants, the right seal makes all the difference in the world of mechanical engineering.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories