Sep . 03, 2024 02:48 Back to list

Combi Oil Seal – High-Quality Seals for Enhanced Performance

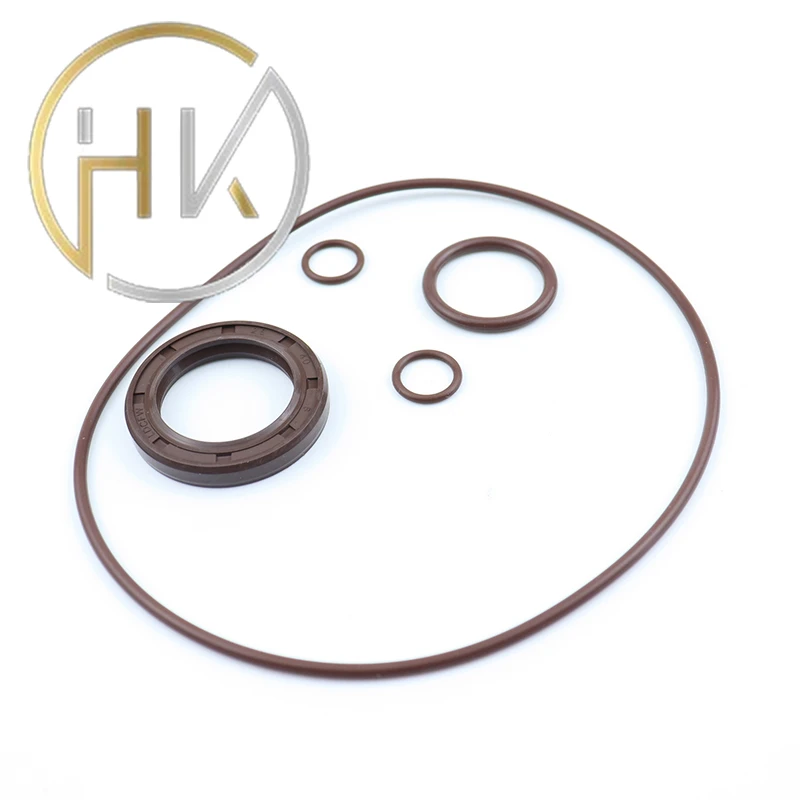

Understanding Combi Oil Seals A Comprehensive Overview

In the realm of mechanical engineering and automotive applications, oil seals play a crucial role in ensuring the efficiency and longevity of machinery. Among the various types of oil seals, the combi oil seal has gained popularity due to its unique design and versatile applications. This article aims to provide an informative overview of combi oil seals, their composition, functionality, and applications.

What is a Combi Oil Seal?

A combi oil seal, as the name suggests, combines the functions of various sealing technologies into a single unit. Typically, it consists of two primary sealing elements a rubber lip that prevents oil leakage and a component that withstands high radial forces and dirt contamination. This dual design not only enhances sealing efficiency but also simplifies installation and maintenance procedures.

Key Features and Benefits

1. Leak Prevention The primary purpose of the combi oil seal is to prevent the leakage of lubricating oil from machinery components. This is essential for maintaining proper lubrication and preventing wear and tear on moving parts.

2. Durability Combi oil seals are designed to resist various environmental factors including temperature fluctuations, oil exposure, and contaminants such as dirt and dust. This durability ensures a longer lifespan, reducing the frequency of replacements.

3. Versatility These seals can be used in a wide range of applications, including automotive engines, transmissions, and industrial machinery. Their adaptability makes them a favored choice among engineers and manufacturers.

combi oil seal

4. Simplified Installation The compact design of combi oil seals allows for easier installation compared to traditional sealing methods that may require multiple components. This can lead to significant time savings during assembly.

Material Composition

Combi oil seals are typically made from high-grade elastomers, such as Nitrile rubber (NBR) or Fluoroelastomers (FKM), which offer excellent resistance to oils and fuels. These materials are selected based on their ability to withstand various operational conditions, including temperature extremes and chemical exposure. Reinforcement materials may also be used to enhance strength and flexibility.

Applications

Combi oil seals find their applications in numerous industries. In automotive engineering, they are commonly used in engine oil pans, differential cases, and transmission systems. In industrial machinery, they protect rotating shafts in pumps, motors, and gearboxes. The effectiveness of these seals in various environmental conditions makes them invaluable in meeting strict industry standards.

Conclusion

In conclusion, combi oil seals represent a significant advancement in sealing technology, offering a multi-functional solution for preventing oil leaks and protecting critical components. Their unique design, coupled with durable materials, ensures they meet the demanding requirements of modern machinery and vehicles. As industries continue to evolve, the importance of reliable sealing solutions like combi oil seals will undoubtedly increase, contributing to improved performance and efficiency across various applications. Whether in automotive, industrial, or even aerospace applications, understanding and implementing combi oil seals can enhance operational reliability and reduce maintenance costs, making them an indispensable asset in any mechanical engineering toolkit.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories