Sep . 08, 2024 10:11 Back to list

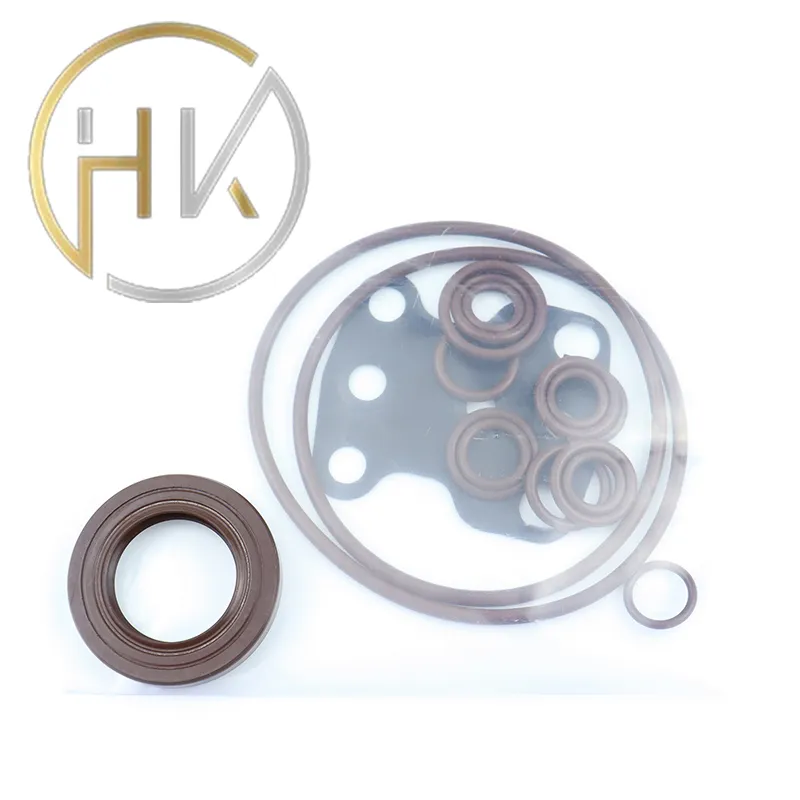

Chief Hydraulic Cylinder Seal Kit - High-Quality Seals for Efficient Performance

Understanding Chief Hydraulic Cylinder Seal Kits

Hydraulic systems are integral to various machinery and equipment, functioning to transmit power through fluid. At the heart of these systems lie hydraulic cylinders, which convert hydraulic energy into mechanical force. However, to maintain optimal performance, hydraulic cylinders rely on a series of components, one of the most critical being the seal kit. Chief hydraulic cylinder seal kits stand out in this regard, offering durability and reliability for various applications.

Understanding Chief Hydraulic Cylinder Seal Kits

Chief hydraulic cylinder seal kits are engineered to meet and exceed industry standards. Made from high-quality materials like polyurethane, nitrile, and fluorocarbon, these seals are designed to withstand extreme temperatures and pressures typical in hydraulic applications. They resist wear and tear, aging, and the harsh chemicals often found in hydraulic fluids, making them suitable for a wide variety of environments and industries, from construction to manufacturing.

chief hydraulic cylinder seal kit

Installation of a seal kit is a straightforward process, but it requires some technical knowledge. First, it's essential to ensure that the hydraulic cylinder is thoroughly cleaned before replacing the old seals. Any contaminants remaining in the cylinder can damage the new seals, leading to premature failure. Proper alignment during installation is also crucial, as misalignment can result in uneven wear and leaks.

Regular maintenance of hydraulic systems is key to prolonging the lifespan of hydraulic cylinders and their components. Replacing seal kits at regular intervals not only prevents leaks but also enhances performance efficiency, reduces system downtime, and minimizes repair costs. It is advisable to consult with a professional or refer to the manufacturer’s guidelines to determine the appropriate maintenance schedule for hydraulic systems.

In summary, Chief hydraulic cylinder seal kits play a vital role in ensuring the efficient operation of hydraulic systems. By choosing high-quality seal kits, operators can enjoy reliable performance and extend the life of their machinery. Whether in heavy machinery, automotive applications, or industrial settings, investing in reliable hydraulic seal kits pays off in performance and cost savings in the long run. Always ensure that you select the correct kit for your specific application to reap the maximum benefits from your hydraulic system.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories