Jan . 31, 2025 05:32 Back to list

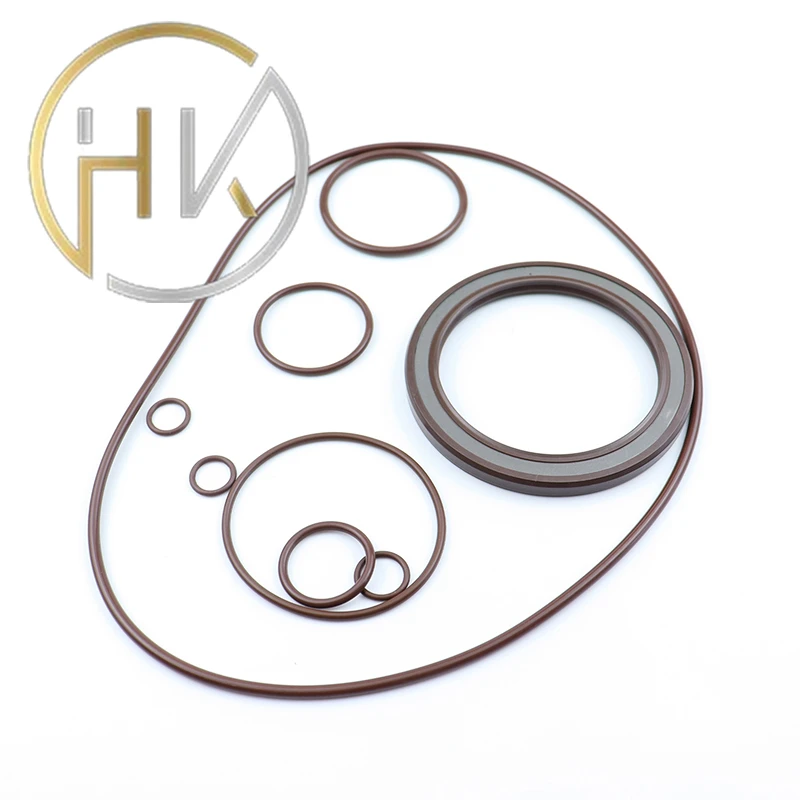

Standard High Pressure TCV Type Hydraulic Oil Seal

The authoritative knowledge surrounding cassette oil seals extends beyond manufacturing into their application and maintenance. Proper installation is crucial and requires adherence to specific guidelines to ensure the integrity of the seal. Expert technicians are trained to recognize the subtle cues of wear and tear and are knowledgeable about the latest advancements in sealing technologies. Their insights are invaluable, providing assurance that systems remain leak-free and contaminants are kept at bay. Moreover, the burgeoning importance of sustainability has influenced the development of cassette oil seals. Manufacturers are increasingly focused on creating eco-friendly designs that reduce waste and improve recyclability. This aligns with global efforts to minimize the environmental impact of industrial processes, offering a compelling reason for industries to adopt advanced sealing solutions. Trust in cassette oil seals is further bolstered by rigorous testing standards. Companies implement comprehensive testing programs to simulate operating conditions and ensure that seals can withstand the harsh environments in which they'll be deployed. This commitment to quality underlines the confidence that industries place in these products, assuring clients of their reliability over time. Ultimately, choosing the right cassette oil seal is indispensable for optimal performance and safety of machinery. It is recommended that decision-makers consult with certified professionals when selecting seals to ensure that the choice aligns with specific operational needs. The expertise of seasoned professionals can guide procurement processes, from selecting the right materials to advising on installation best practices. As technology progresses, the ongoing refinement of cassette oil seals remains a testament to innovation in engineering. Their continued evolution promises to deliver even greater efficiencies and protections, securing their role as a foundational element in the machinery of tomorrow. Embracing these advancements today can significantly position industries for success by ensuring their equipment operates smoothly, safely, and efficiently for years to come.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories