Nov . 14, 2024 08:01 Back to list

cassette oil seal

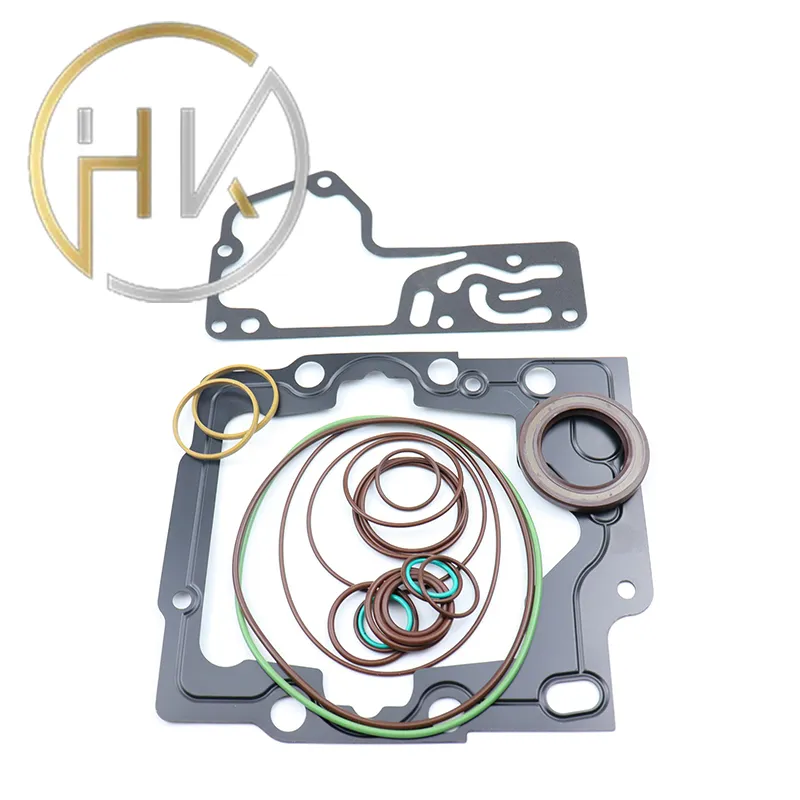

Understanding Cassette Oil Seals Importance and Applications

In the realm of mechanical engineering, ensuring the proper functioning of machines and engines is paramount. One component that plays a crucial role in this endeavor is the cassette oil seal. Often overlooked, these seals are vital in preventing oil leakage, ensuring optimal performance, and extending the lifespan of machinery.

What is a Cassette Oil Seal?

A cassette oil seal, sometimes referred to as a rotary shaft seal or lip seal, is a type of sealing device used to prevent the escape of lubricants (like oil) from a rotating shaft. The seal comprises several essential components, including a metal outer casing, a rubber sealing lip, and a spring (in many designs) that helps maintain contact with the shaft. Its design allows it to operate under various pressures and speeds, making it suitable for diverse applications.

Importance of Cassette Oil Seals

1. Preventing Oil Leakage The primary function of a cassette oil seal is to prevent oil from leaking out of the machinery. Oil is crucial for lubrication, which reduces friction between moving parts. When oil leaks, not only does it undermine lubrication, but it can also lead to significant wear and tear on machinery components.

2. Maintaining Performance When seals function properly, they help maintain the efficiency and performance of machines. Any oil loss can lead to overheating as friction increases, causing machines to operate inefficiently. This can result in premature failure of various components, leading to costly repairs or replacements.

cassette oil seal

3. Environmental Protection Oil leakage can have disastrous environmental impacts. It can contaminate the soil and water, posing risks to ecosystems and human health. By using effective cassette oil seals, industries can mitigate these risks and adhere to environmental regulations.

4. Cost Effectiveness From a financial perspective, proper sealing can save money. Preventing oil loss minimizes the need for frequent oil replenishment and reduces maintenance costs. Moreover, a machine functioning efficiently reduces energy consumption, leading to lower operational costs over time.

Applications of Cassette Oil Seals

Cassette oil seals are used across a myriad of industries, from automotive to manufacturing. In automotive applications, these seals are found in engines, transmissions, and differentials, where they protect critical components from oil loss. In industries such as construction and agriculture, heavy machinery relies on these seals to remain operational, as they often face harsh working conditions.

The versatility of cassette oil seals extends to small household appliances as well. From washing machines to lawnmowers, these seals help maintain performance and longevity by keeping lubricants in and contaminants out.

Conclusion

Cassette oil seals may seem like minor components in the grand scheme of machinery and engines, but their role is undeniably significant. By preventing oil leakage, maintaining performance, and protecting the environment, they contribute to the efficient operation of countless machines across various industries. With proper maintenance and timely replacement, these seals play a crucial role in ensuring that equipment runs smoothly, efficiently, and sustainably. As technology advances, so too will the designs and materials used in cassette oil seals, promising even better performance and reliability for the future.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories