Dec . 11, 2024 00:02 Back to list

Replacement Seal Kit for Boom Cylinder Maintenance and Repair

Understanding Boom Cylinder Seal Kits Importance and Selection Guide

In heavy machinery, particularly in the realm of construction and industrial applications, hydraulic systems play a pivotal role in ensuring efficient operation. Among the critical components of these systems are boom cylinders, which are essential for the operation of cranes, excavators, and various other lifting equipment. To maintain the performance and reliability of boom cylinders, seal kits are an indispensable part. This article will explore the importance of boom cylinder seal kits, their components, and key factors to consider when selecting them.

The Importance of Seal Kits

Boom cylinder seal kits are designed to prevent hydraulic fluid leaks, ensure smooth operation of moving parts, and protect the hydraulic system from contaminants. The importance of these seal kits cannot be overstated, as any failure in the seals can lead to reduced efficiency, increased wear and tear, and potential downtime due to repairs. When a boom cylinder operates, it undergoes a significant amount of pressure and movement, making quality seals crucial for maintaining hydraulic integrity.

Without effective sealing solutions, hydraulic fluids could leak, leading to significant performance drops and potential catastrophic failures. Increased wear on components due to hydraulic fluid loss can also result in costly repairs. Thus, investing in quality seal kits contributes to the longevity and efficiency of boom cylinders, ultimately reducing maintenance costs and enhancing operational safety.

Components of a Seal Kit

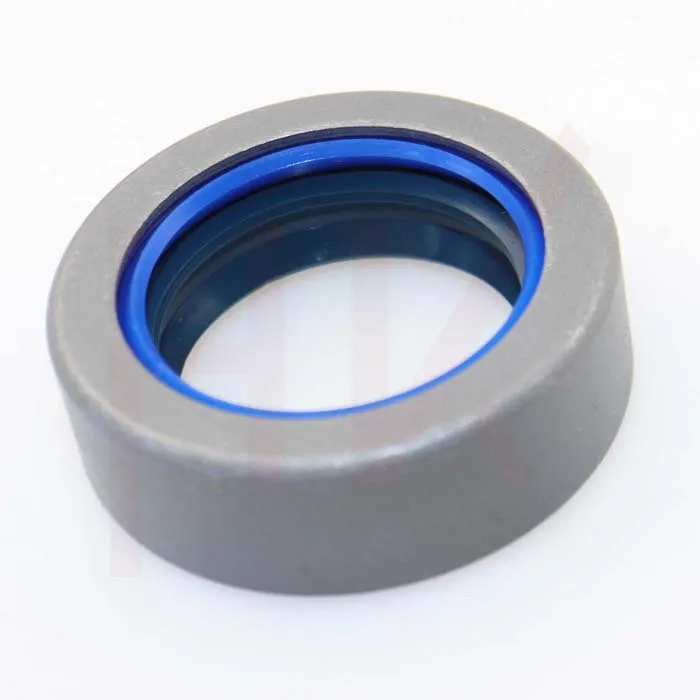

A boom cylinder seal kit typically contains various types of seals, including O-rings, piston seals, and rod seals

. Understanding each component's role is essential for ensuring proper installation and optimal functioning1. O-Rings These are circular seals that are used to create a static seal between two surfaces. O-rings can be found in numerous locations within the hydraulic system and are crucial for preventing leakage.

2. Piston Seals Designed to seal the fluid from escaping the cylinder when high pressure is applied, piston seals are vital for ensuring the proper operation of the boom. They maintain pressure integrity and help in regulating the cylinder's movement.

3. Rod Seals These seals prevent the hydraulic fluid from escaping as the rod moves in and out of the cylinder. Like piston seals, they are essential for maintaining pressure while also protecting the rod from contaminants.

boom cylinder seal kit

4. Back-Up Rings Used in conjunction with O-rings and seals, back-up rings prevent extrusion of the seals when the vehicle is under high pressure, providing additional support and extending the life of the primary sealing elements.

Selecting the Right Seal Kit

Choosing the right boom cylinder seal kit is critical to ensure compatibility and operational efficiency. Here are some essential factors to consider

1. Compatibility Ensure that the seal kit is designed for the specific make and model of your boom cylinder. Different hydraulic systems may have unique specifications that require particular seals.

2. Material Quality The material of the seals should be suited for the operating environment. Common materials include nitrile, polyurethane, and PTFE; each has different resistance to temperature, pressure, and chemicals.

3. Manufacturer Specifications Always refer to the manufacturer's guidelines for appropriate seal kits. OEM (Original Equipment Manufacturer) seal kits are often recommended for optimal compatibility and performance.

4. Cost vs. Quality While it may be tempting to choose lower-cost options, remember that quality seals can offer long-term savings by preventing leaks and reducing wear on other components.

Conclusion

In conclusion, boom cylinder seal kits are vital elements in the maintenance and operation of hydraulic systems in heavy machinery. Understanding their components, importance, and selection criteria can greatly enhance the efficiency and longevity of your equipment. By investing time and resources into choosing the right seal kits, operators can ensure their machinery performs reliably, minimizes downtime, and achieves maximum productivity on the job site.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories