Oct . 16, 2024 14:00 Back to list

boom cylinder seal kit

Understanding Boom Cylinder Seal Kits Essential Components for Hydraulic Systems

Boom cylinder seal kits are vital components in hydraulic systems, particularly in heavy machinery such as excavators, cranes, and aerial lifts. These kits are designed to maintain the integrity and functionality of boom cylinders, ensuring that they operate efficiently and reliably.

The primary function of a boom cylinder is to lift and lower the boom of the machine, which necessitates the use of hydraulic fluid. Over time, seals within the cylinder can wear out due to constant pressure and friction, leading to leaks and decreased performance. This is where seal kits come into play.

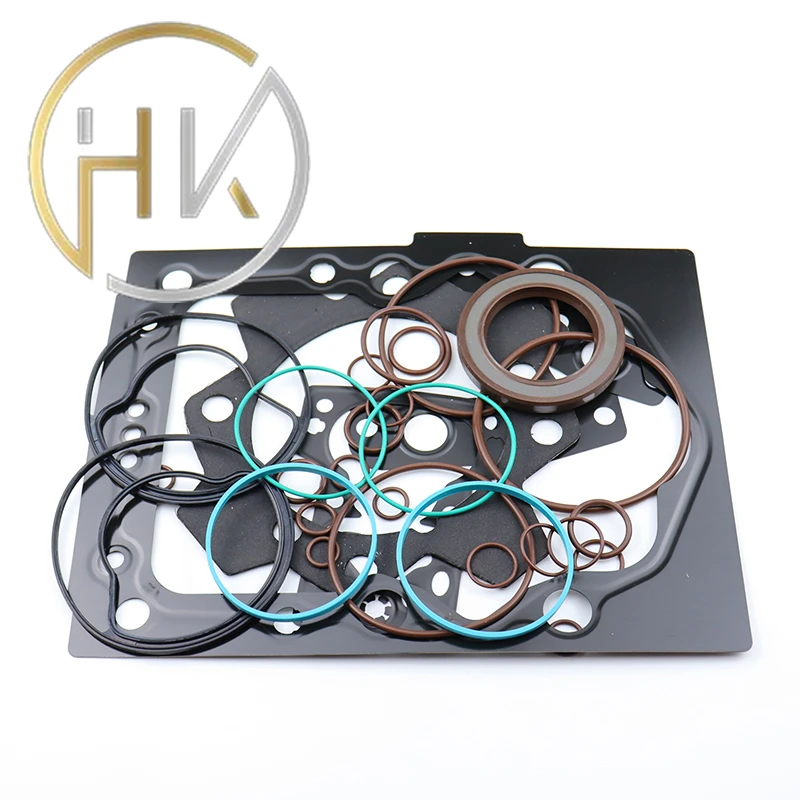

A typical boom cylinder seal kit contains various seals, O-rings, and gaskets, specifically engineered to match the dimensions and requirements of the hydraulic cylinder. These components work together to prevent hydraulic fluid from leaking out and to keep contaminants from entering the system. By replacing old or worn seals with a new seal kit, operators can restore the hydraulic system's functionality and extend the lifespan of the equipment.

boom cylinder seal kit

When selecting a boom cylinder seal kit, it is essential to consider factors such as the type of machinery, the operating environment, and the specific fluid being used

. Different applications may require different materials for seals, such as rubber, polyurethane, or PTFE, each offering unique properties suitable for various environments.Regular maintenance and timely replacement of boom cylinder seals can lead to significant cost savings. Hydraulic leaks not only waste fluid but also lead to increased operating costs and potential damage to the machinery. By routinely inspecting the seals and using high-quality boom cylinder seal kits, operators can ensure that their equipment runs smoothly and efficiently.

Furthermore, the installation of a seal kit requires some technical knowledge. While many operators and mechanics are capable of performing this task, others may opt to seek professional assistance. Proper installation is crucial, as incorrect fitting can lead to premature failure of the seals and additional repairs down the line.

In conclusion, boom cylinder seal kits are essential for maintaining the performance and reliability of hydraulic systems in heavy machinery. By understanding their components, choosing the right kit for specific applications, and prioritizing regular maintenance, operators can ensure that their equipment operates at peak performance for years to come. Investing in quality seal kits not only enhances efficiency but also promotes safety and reliability in the workplace.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories