Nov . 12, 2024 11:40 Back to list

backhoe cylinder seal kits

Understanding Backhoe Cylinder Seal Kits Essential Components for Optimal Performance

Backhoes are versatile machines widely used in construction, landscaping, and excavation. They come equipped with various hydraulic systems that enable them to perform a range of tasks, from digging trenches to lifting heavy materials. Central to the efficient operation of these hydraulic systems are the cylinder seal kits, which play a critical role in ensuring the durability and reliability of hydraulic cylinders.

What are Cylinder Seal Kits?

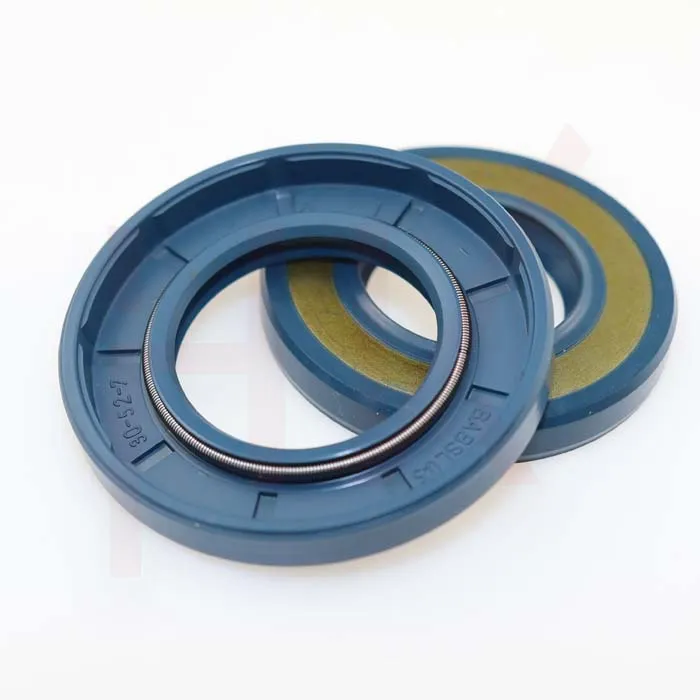

Cylinder seal kits consist of a collection of seals, O-rings, gaskets, and other hydraulic components designed to prevent leaks and ensure optimal performance in hydraulic cylinders. These kits are tailored to specific equipment and are vital for maintaining hydraulic pressure while preventing contaminants from entering the system. The integrity of these seals is crucial, as even the slightest leak can lead to significant performance issues and costly repairs.

Importance of Seal Kits in Backhoes

1. Preventing Hydraulic Leaks The primary function of seal kits is to create a tight seal between moving components, which prevents hydraulic fluid from leaking out of the cylinder. This is crucial because hydraulic systems operate under high pressure, and any loss of fluid can diminutively affect the machine's overall performance.

2. Enhancing Efficiency Well-functioning seals ensure that hydraulic cylinders operate smoothly and efficiently. When seals are compromised, it can lead to decreased efficiency, causing the engine to work harder to compensate for lost pressure, which can result in increased fuel consumption and wear on the machine.

3. Extending Component Lifespan Regular maintenance and replacement of worn-out seals can significantly extend the life of hydraulic cylinders. This preventative measure can help avoid costly replacements and downtime caused by hydraulic failures.

4. Ensuring Safety Hydraulic systems that are leaking or malfunctioning can pose safety hazards. Ensuring that seal kits are properly maintained helps to minimize risks associated with hydraulic failures, protecting both the operator and the machine.

Choosing the Right Seal Kit

Selecting the appropriate backhoe cylinder seal kit requires careful consideration of several factors

.1. Compatibility It is essential to ensure that the seal kit is compatible with the specific model and make of the backhoe. Using the wrong seals can lead to poor performance and increased risks of leaks.

backhoe cylinder seal kits

2. Material Quality The quality of the materials used in seal manufacturing can affect the longevity and effectiveness of the seals. High-quality materials, such as polyurethane and nitrile rubber, are often more resistant to wear, heat, and hydraulic fluids.

3. Environmental Conditions Backhoes often operate in various environments that can affect seal life. Consideration should be given to factors like temperature extremes, exposure to dirt and debris, and the type of hydraulic fluid used.

4. Brand Reputation Opting for seal kits from reputable manufacturers can provide peace of mind regarding quality and reliability. Well-known brands might offer better warranties and support, ensuring that you receive a product that meets industry standards.

Maintenance Tips

To ensure the longevity and performance of backhoe cylinder seal kits, regular maintenance is crucial. Here are some tips

1. Routine Inspections Regularly inspect hydraulic cylinders for signs of leaks or wear. Early detection can prevent costly repairs and downtime.

2. Fluid Changes Ensure that hydraulic fluids are changed according to the manufacturer’s recommendations. Contaminated fluid can deteriorate seals quicker than clean fluid.

3. Environment Control Keep the machine clean and free of debris that could damage seals. Using covers when the machine is not in operation can help protect it from contaminants.

4. Professional Assistance Consult with professionals for installation or replacement of seal kits. Proper installation is key to ensuring seals work effectively.

Conclusion

Backhoe cylinder seal kits are fundamental components that ensure hydraulic systems operate efficiently and effectively. By understanding their importance and taking proactive measures to maintain them, operators can extend the life of their equipment, enhance safety, and boost productivity on the job site. Investing in quality seal kits and adhering to a regular maintenance schedule is essential for any backhoe owner or operator looking to maximize their investment.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories