Dec . 11, 2024 09:13 Back to list

High Quality 70x90x10mm Oil Seal for Reliable Sealing Performance and Durability

Understanding the 70x90x10 Oil Seal Importance and Applications

In the realm of mechanical engineering, the reliability and efficiency of machines are paramount. One of the critical components that contribute to this efficiency is the oil seal. Among various types, the 70x90x10 oil seal stands out due to its specific dimensions and applications. In this article, we will delve into the intricacies of the 70x90x10 oil seal, its significance, material composition, applications, and maintenance tips.

What is an Oil Seal?

An oil seal, also known as a grease seal or shaft seal, is a sealing device used to prevent the leakage of lubricants (like oil or grease) and the ingress of contaminants (such as dirt and water) into the machinery. They are essential in maintaining the integrity and longevity of various mechanical systems by ensuring that the lubricants remain in their designated areas, thereby minimizing friction and wear.

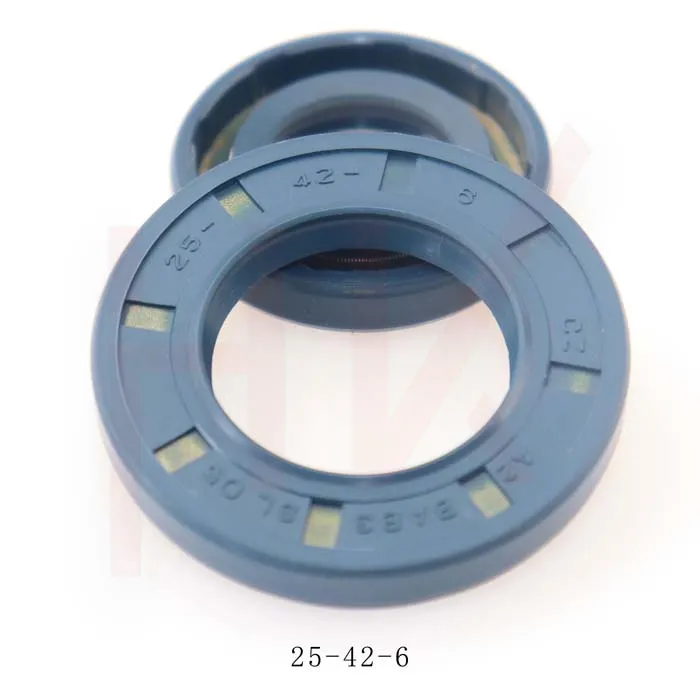

Dimensions and Specifications

The designation 70x90x10 refers to the dimensions of the oil seal. The first number, 70, represents the inner diameter in millimeters. The second number, 90, indicates the outer diameter, also in millimeters. Lastly, the third number, 10, denotes the width or thickness of the seal. Understanding these dimensions is crucial because they need to match the specific application for optimal performance.

In addition to dimensions, oil seals can be classified based on various factors including material, design, and resistance properties (to temperature, pressure, and chemicals). The 20 in the 70x90x10 designation might refer to specific variations, such as a certain material grade or a compliance marking.

Material Composition

Oil seals are typically made from materials that can withstand harsh operating conditions. Common materials include

- Nitrile Rubber (NBR) Known for its excellent resistance to oil and moderate temperature fluctuations. It is suitable for most automotive and industrial applications. - Fluoroelastomer (FKM) Offers superior heat and chemical resistance, making it ideal for high-performance applications, especially in the aerospace and automotive sectors.

- Silicone While not as oil-resistant as nitrile, silicone oil seals perform well in extreme temperature environments, boasting a high degree of flexibility.

The choice of material impacts not only the lifespan of the seal but also its effectiveness in different operating environments.

Applications of 70x90x10 Oil Seal

The 70x90x10 oil seal is versatile and finds applications in various industries, including

70x90x10 oil seal

- Automotive Industry Commonly used in engines, transmissions, and differentials where lubrication is essential for smooth operation.

- Industrial Machinery Found in pumps, motors, and gearboxes to prevent oil leaks, which can lead to performance degradation and increased maintenance costs.

- Agricultural Equipment Used in various farming machinery to ensure that moving parts remain well-lubricated and protected from external contaminants.

- Aerospace Employed in specific applications, especially where high performance and reliability are crucial, such as in landing gears and hydraulic systems.

Maintenance Tips for Oil Seals

Maintaining the integrity of oil seals is vital for the overall performance of machinery. Here are some tips to extend the lifespan of oil seals

1. Regular Inspection Periodically check for signs of wear, leakage, or damage. Early detection of issues can prevent costly repairs.

2. Correct Installation Ensure that the oil seal is installed correctly, with the right tools and techniques. An improper fit can lead to premature failure.

3. Avoid Contaminants Keep the installation area clean to prevent dirt and debris from compromising the seal.

4. Lubrication Compatibility Ensure that the lubricants used are compatible with the oil seal material to prevent degradation.

5. Monitor Operating Conditions Keep an eye on temperature and pressure levels that may affect seal performance.

Conclusion

The 70x90x10 oil seal plays a crucial role in the efficiency and reliability of various machines across different industries. Understanding its dimensions, materials, applications, and maintenance can lead to better decision-making and enhanced machinery performance. As technology continues to evolve, so too will the designs of oil seals, further cementing their importance in engineering and manufacturing processes.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories