Dec . 11, 2024 10:32 Back to list

Effective Oil Seals for Optimal Performance in Machinery and Equipment Applications

Understanding the 70% 2090% 2010% Oil Seal A Comprehensive Overview

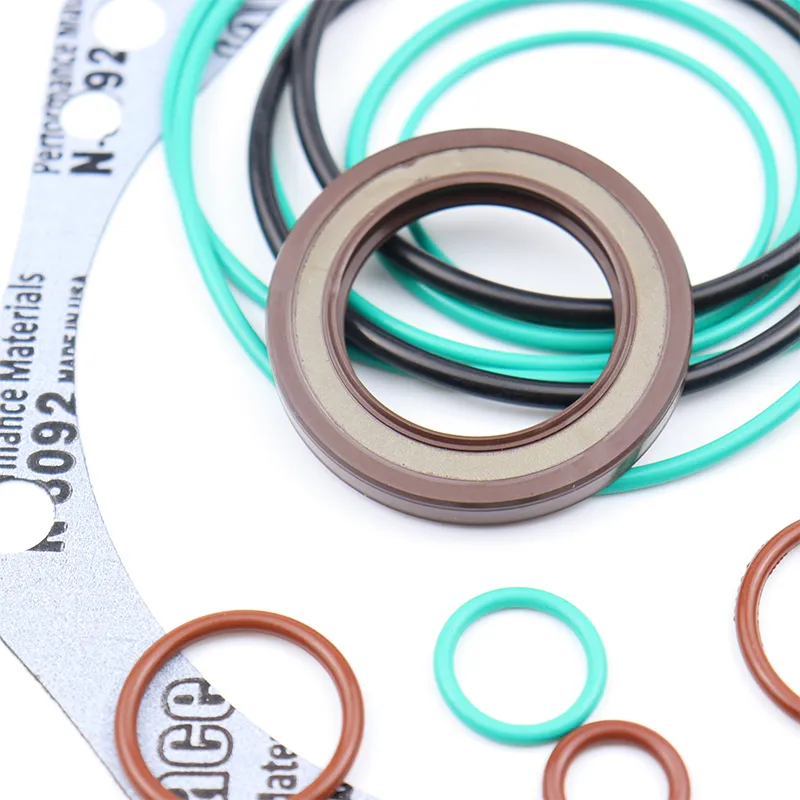

In various industrial applications, the integrity and performance of equipment are largely dependent on the quality of seals. Among these, oil seals play a crucial role in ensuring the efficient operation of machinery by preventing lubrication leakage and contamination. One widely discussed type of oil seal is the 70% 2090% 2010% oil seal, which refers to specific ratios and classifications that elucidate its performance characteristics and material composition.

What is an Oil Seal?

An oil seal, also known as a fluid seal or rotary seal, is a device that protects machinery by sealing the gaps — particularly in rotating shafts — where fluids can escape or enter. The primary function of an oil seal is to retain lubricants, thereby reducing wear and tear on moving parts. They are commonly utilized in automotive, industrial, and aerospace applications.

The Composition of 70% 2090% 2010% Oil Seal

The designation of 70% 2090% 2010% relates to the seal's material composition and performance specifications. Understanding this classification can significantly influence the choice of oil seal for a specific application.

- 70% Material Composition This indicates that 70% of the material used in the oil seal construction can be synthetic rubber or elastomers, which offer excellent resistance to heat, wear, and chemical exposure. Materials such as nitrile rubber (NBR) or fluorocarbon (FKM) might be included in this percentage, depending on the required application and the compatibility with various oils.

- 2090% Performance Rate This could reflect the seal's ability to operate efficiently under specific conditions, indicating that it maintains integrity in a temperature range of -20°C to 120°C for prolonged periods. The 2090% might also suggest durability against a specific pressure range, ensuring that even under extreme operational conditions, the seal remains effective.

- 2010% Durability Standard This part of the classification could describe the expected lifespan or the number of operational cycles the oil seal can endure before failure occurs. A 2010% ratio may correlate with high-end manufacturing standards, where the seal could be tested to withstand harsh environments and prolonged use.

70 90 10 oil seal

Applications and Advantages

The 70% 2090% 2010% oil seal is often employed in environments where high performance and reliability are crucial. For example, in automotive engine components, these seals prevent oil from leaking out, which can lead to engine wear and failure. In industrial machinery, they help maintain lubrication within hydraulic systems, ensuring efficient performance.

Moreover, the advantages of using this type of oil seal include

1. Improved Reliability By preventing leaks and contamination, oil seals contribute to the overall reliability of machinery, extending the life of components.

2. Cost-Efficiency Although high-quality seals may come at a higher initial cost, their longevity and effectiveness ultimately lead to cost savings in maintenance and repairs.

3. Versatility The 70% 2090% 2010% oil seal can be used across various applications, from automotive to industrial machinery, making it a versatile choice for many industries.

4. Enhanced Performance By providing effective sealing solutions, these oil seals help maintain optimal operation, enhancing the performance of machinery and equipment.

Conclusion

The 70% 2090% 2010% oil seal exemplifies how specific material compositions and performance standards can significantly impact the reliability and efficiency of machinery across numerous applications. Understanding the characteristics of such seals allows engineers and maintenance professionals to make informed decisions, ensuring the longevity and functionality of their equipment. With advancements in materials and manufacturing technologies, oil seals continue to evolve, paving the way for safer and more efficient industrial practices. Whether in the automotive industry or heavy machinery, the role of oil seals remains indispensable for maintaining operational integrity and maximizing performance.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories