Oct . 05, 2024 14:36 Back to list

Oil Seal Specifications for 70%, 90%, and 10% Performance Standards

Understanding the 70/90/10 Oil Seal Importance and Applications

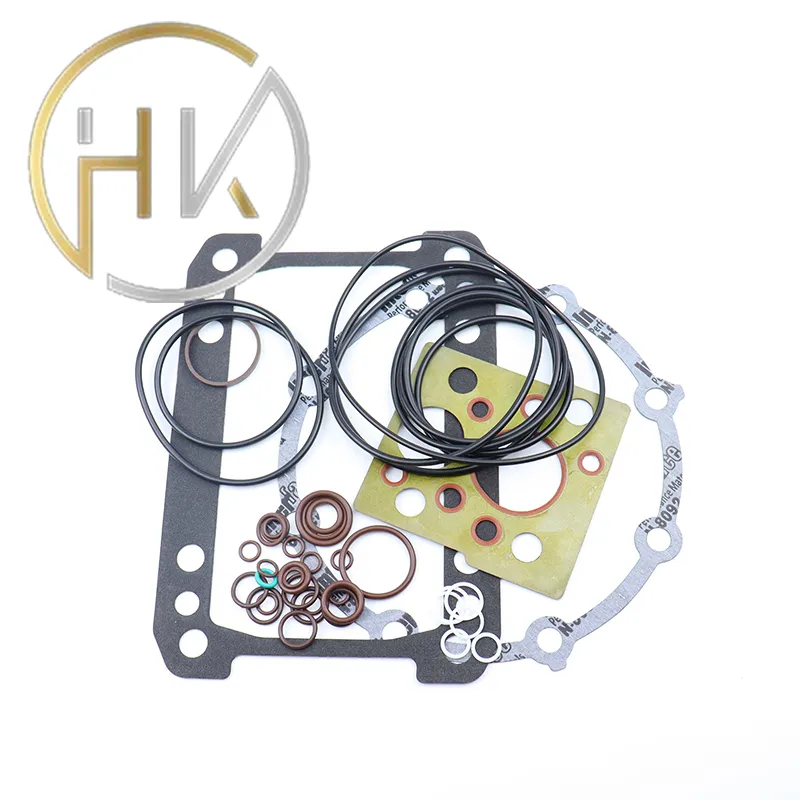

Oil seals, also known as radial lip seals, are essential components in various machinery and equipment, effectively preventing the leakage of lubricants while keeping contaminants out. Among the myriad types available, the 70/90/10 oil seal stands out due to its specific design and functionality that are critical in maintaining operational efficiency.

Understanding the 70/90/10 Oil Seal Importance and Applications

Oil seals are designed to function in diverse environments, operating under varying temperatures, pressures, and exposure to contaminants. The efficacy of the 70/90/10 oil seal largely depends on the materials used in its production. Common materials include nitrile rubber, fluorocarbon rubber, and polyurethane. Nitrile rubber, known for its excellent resistance to petroleum-based oils and increased durability in dynamic applications, is frequently used in these seals. In contrast, fluorocarbon rubber provides superior resistance to high temperatures and aggressive chemicals, making it ideal for specialized applications.

70 90 10 oil seal

The benefits of utilizing a 70/90/10 oil seal are manifold. Firstly, it contributes to improved efficiency in machinery. By preventing oil leaks, the seal reduces the amount of lubricant required, ensuring that machinery operates smoothly without excessive wear. Secondly, it enhances the longevity of equipment. Contaminants such as dust and water can lead to significant damage if allowed to penetrate machinery. The 70/90/10 oil seal acts as a barrier, prolonging the lifespan of the machinery and reducing maintenance costs.

In addition to automotive applications, these seals are widely used in various industrial settings. They can be found in hydraulic systems, pumps, conveyor systems, and even household appliances such as washing machines. The versatility of the 70/90/10 oil seal indicates its vital role in modern engineering and manufacturing processes.

In conclusion, the 70/90/10 oil seal is more than just a simple component; it is crucial for ensuring the reliability and efficiency of numerous mechanical systems. By understanding its specifications, material composition, and applications, engineers and technicians can make informed decisions in their design and maintenance practices, ultimately leading to enhanced performance and productivity in their operations. As technology advances, the development of more resilient and efficient oil seals will continue to play a significant role in the evolution of machinery and equipment.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories