Jan . 11, 2025 09:38 Back to list

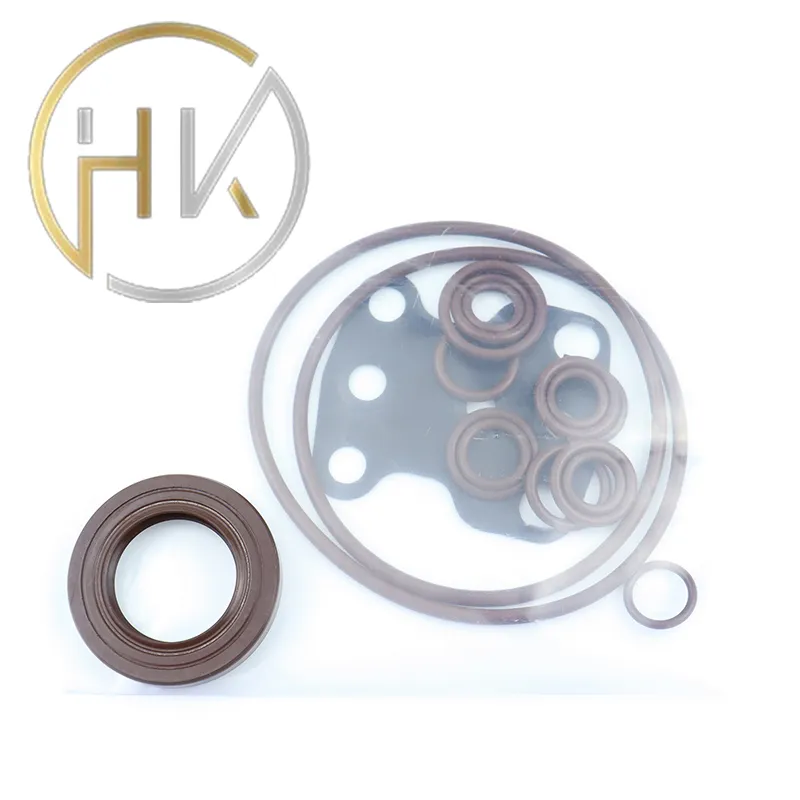

50x65x8 oil seal

The authority in designing and manufacturing these seals is firmly with companies that adhere to rigorous industry standards. They ensure that each 50x65x8 seal produced not only meets but often exceeds the expectations of endurance and functionality. Such companies invest in research and development, testing seals under various conditions to validate their performance. Certifications from recognized industry bodies add an extra layer of assurance for users, confirming that these products comply with international safety and quality standards. Trust in the 50x65x8 oil seal is fostered through a commitment to quality and performance. Engineers and end-users alike depend on the dependability of these seals in safeguarding equipment. Open channels of feedback and transparent business practices by manufacturers further solidify this trust, addressing user concerns promptly to enhance product offerings continually. In summary, the 50x65x8 oil seal is a specialized component that serves as a cornerstone of machinery maintenance and reliability. Its popularity among professionals stems from a combination of precise engineering, robust material choices, and a strong adherence to quality standards. It’s not simply a product; it’s a testament to the expertise, authority, and trust that experienced manufacturers instill in their consumers. Every application of this oil seal reflects the culmination of expert knowledge and practical experience that ensures machinery operates without interruption, supporting the myriad industries that depend on these machines every day.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories