Dec . 23, 2024 12:29 Back to list

50x65x8 oil seal

Understanding the 50x65x8% Oil Seal A Critical Component in Mechanical Engineering

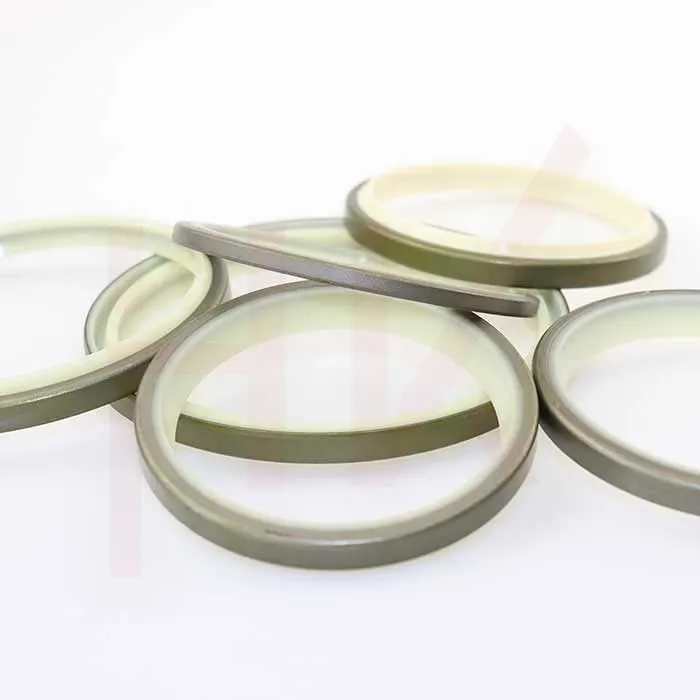

Oil seals are essential components used in various machinery and applications to prevent the leakage of lubricants and keep contaminants out. One particular size, the 50x65x8 oil seal, plays a significant role in ensuring the efficient operation of mechanical systems. This article will delve into the specifics of this oil seal, its applications, and the importance of selecting the right components for mechanical assemblies.

What is an Oil Seal?

An oil seal, also known as a radial lip seal or grease seal, is designed to retain lubricants in components such as bearings, gearboxes, and hydraulic systems. These seals prevent oil and grease from leaking out of moving parts, which is crucial for the longevity and performance of machinery. The 50x65x8 designation refers to the dimensions of the seal a 50 mm inner diameter, a 65 mm outer diameter, and an 8 mm thickness. Understanding these dimensions is vital for ensuring compatibility with specific components where these seals will be used.

Importance of a Proper Fit

In mechanical engineering, the fit of an oil seal is vital. An improper fit can lead to various issues, including lubricant leakage, wear and tear on components, and ultimately, equipment failure. The 50x65x8 oil seal must be correctly matched to the shaft it is intended to seal. If the inner diameter is too large, it will not create a proper seal, leading to potential lubricant loss and contamination ingress. Conversely, if the outer diameter does not fit snugly in the housing, the seal may dislodge or fail prematurely.

Materials and Types of Oil Seals

50x65x8 oil seal

Oil seals are typically made of materials such as rubber, synthetic compounds, or even metal, depending on the application's specific needs. The choice of material affects the seal's durability, elasticity, and temperature resistance. For example, nitrile rubber (NBR) oil seals are widely used because of their excellent resistance to petroleum oils and greases. In contrast, silicone seals may be preferred in high-temperature environments.

The 50x65x8 oil seal may come in various styles, including - Single Lip Best for general applications, featuring one sealing lip that contacts the shaft

. - Double Lip Provides an extra layer of protection against contaminants, suitable for harsher environments. - Spring-loaded Incorporates a spring to improve the sealing performance by constantly pressing the lip against the shaft.Applications of the 50x65x8 Oil Seal

The 50x65x8 oil seal finds applications in various industries. In automotive engineering, for example, these seals are often used in differential housings and transmission systems to retain lubricants. In industrial machinery, they help maintain the necessary lubrication in gearboxes and motors, ensuring smooth operation and preventing failures due to inadequate lubrication.

Hydraulic systems also benefit from oil seals, where they are used to seal hydraulic cylinders, preventing fluid loss and ensuring optimal pressure within the system. The ability of the 50x65x8 oil seal to withstand different pressures and temperatures makes it a versatile choice across multiple industries.

Conclusion

In summary, the 50x65x8 oil seal is a critical component that plays a significant role in various mechanical systems. Selecting the right oil seal is essential for maintaining equipment efficiency and longevity. As machines become more complex, the need for reliable sealing solutions like the 50x65x8 oil seal will only grow. Engineers and maintenance professionals must ensure they understand the specifications, materials, and applications of these seals to make informed decisions that enhance the performance and reliability of machinery.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories