Oct . 18, 2024 09:09 Back to list

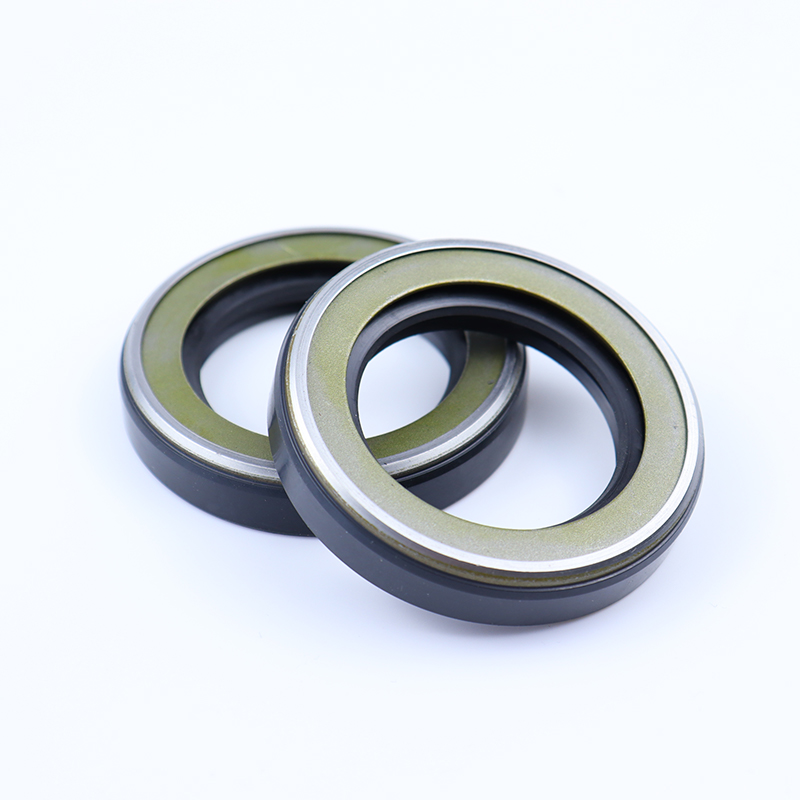

50x65x8mm Oil Seal for Durable Protection and Efficient Performance in Machinery

Understanding the Importance of a 50x65x8 Oil Seal in Mechanical Applications

In the realm of mechanical engineering and maintenance, oil seals play a crucial role in ensuring the effective functioning of machinery. Among the various types of oil seals, the 50x65x8 oil seal stands out due to its specific dimensions and versatile applications. Understanding the properties and benefits of this oil seal can help engineers and maintenance professionals select the right component for their systems.

The dimensions 50x65x8 refer to the inner diameter, outer diameter, and width of the seal in millimeters. Specifically, this oil seal has an inner diameter of 50 mm, an outer diameter of 65 mm, and a thickness of 8 mm. Such specifications make it suitable for a range of applications, particularly in rotating machinery where a tight seal is essential to prevent leakage of lubricants and fluids.

One of the primary functions of the 50x65x8 oil seal is to retain lubricating oil within the machinery

. This is critical because lubrication reduces friction between moving parts, thereby enhancing the efficiency and lifespan of the equipment. Without an effective seal, lubricants could leak out, leading to increased wear and tear, overheating, and, ultimately, mechanical failure.50x65x8 oil seal

In addition to retaining oil, this seal also serves as a barrier against contaminants such as dirt, dust, and water. By preventing foreign particles from entering the machinery, the oil seal plays a vital role in maintaining the integrity of the internal components. This protective function is particularly important in environments where equipment is exposed to harsh conditions, such as in automotive, industrial, or agricultural machinery.

The materials used in the construction of a 50x65x8 oil seal are also noteworthy. Typically made from elastomeric compounds, these seals offer flexibility, durability, and resistance to temperature fluctuations and chemical exposure. This adaptability ensures that the oil seal continues to perform effectively over time, even under demanding circumstances.

Installation and maintenance of the 50x65x8 oil seal are essential for optimal performance. Proper fitting is crucial; a poorly installed seal may cause leaks or premature wear. Regular inspections can help identify any signs of wear or damage, allowing for timely replacements and preventing costly repairs or downtime.

In summary, the 50x65x8 oil seal is an indispensable component in many mechanical systems. Its ability to retain lubricants and protect against contaminants plays a significant role in the longevity and efficiency of machinery. Understanding its importance can aid in better maintenance practices and improved operational reliability.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories