Nov . 18, 2024 10:55 Back to list

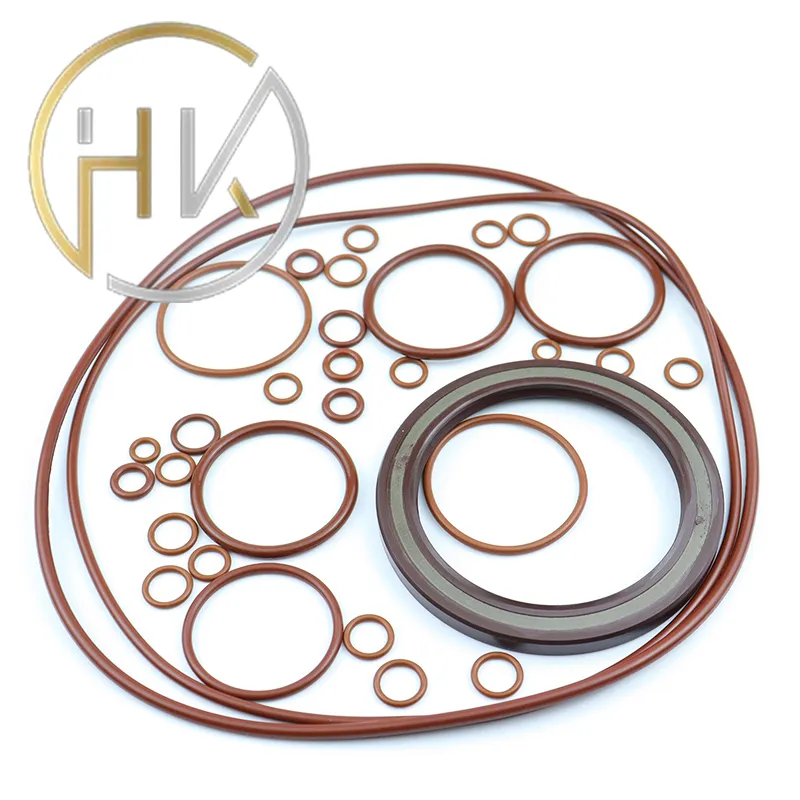

High-Performance 40x55mm Oil Seal for Effective Sealing Solutions and Durability

Understanding the 40x55x8% Oil Seal Specifications and Applications

Oil seals play a crucial role in various mechanical systems, ensuring the smooth operation of moving parts by preventing the leakage of lubricants and the ingress of contaminants. The 40x55x8 oil seal is a specific type of oil seal specified by its dimensions a 40 mm inner diameter, a 55 mm outer diameter, and an 8 mm thickness. This oil seal is widely used in automotive, industrial machinery, and aerospace applications, where reliability and efficiency are paramount.

The design of the 40x55x8 oil seal consists of several components, including a sealing lip, a casing, and a spring

. The sealing lip forms the primary barrier against oil leaks, while the casing provides structural integrity and aids in installation. The spring, usually positioned in a groove at the outer edge of the sealing lip, applies consistent pressure to maintain contact with the shaft surface, ensuring a tight seal even in fluctuating conditions.One of the key benefits of using a 40x55x8 oil seal is its ability to withstand a variety of operating conditions. Made from materials such as nitrile rubber or fluorocarbon elastomers, these seals can resist high temperatures, chemicals, and abrasion, making them suitable for both standard and extreme environments. Their versatility makes them an ideal choice for use in gearboxes, hydraulic pumps, and even in automotive engines.

40x55x8 oil seal

When selecting a 40x55x8 oil seal for specific applications, it is essential to consider various factors such as the operating temperature, pressure conditions, and fluid compatibility. Manufacturers often provide technical data sheets that outline the seal's performance characteristics, helping engineers and technicians make informed decisions.

Installation of the oil seal is equally important to ensure its efficacy. Proper alignment, cleanliness of the sealing surfaces, and the use of appropriate installation tools are critical to avoid damage during the fitting process. If installed incorrectly, even the best quality oil seal can fail, leading to leaks that can compromise system performance and lead to costly repairs.

In summary, the 40x55x8 oil seal is a fundamental component in many mechanical systems, providing effective sealing solutions for various applications. Understanding its specifications, materials, and proper installation techniques is essential for achieving optimal performance and longevity in any machinery that requires reliability and efficiency in oil sealing. By selecting and using the right oil seal, engineers and technicians can enhance system integrity and reduce maintenance costs, ultimately contributing to the overall success of their projects.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories