Oct . 30, 2024 20:35 Back to list

40x55x8 oil seal

Understanding the 40x55x8 Oil Seal A Comprehensive Guide

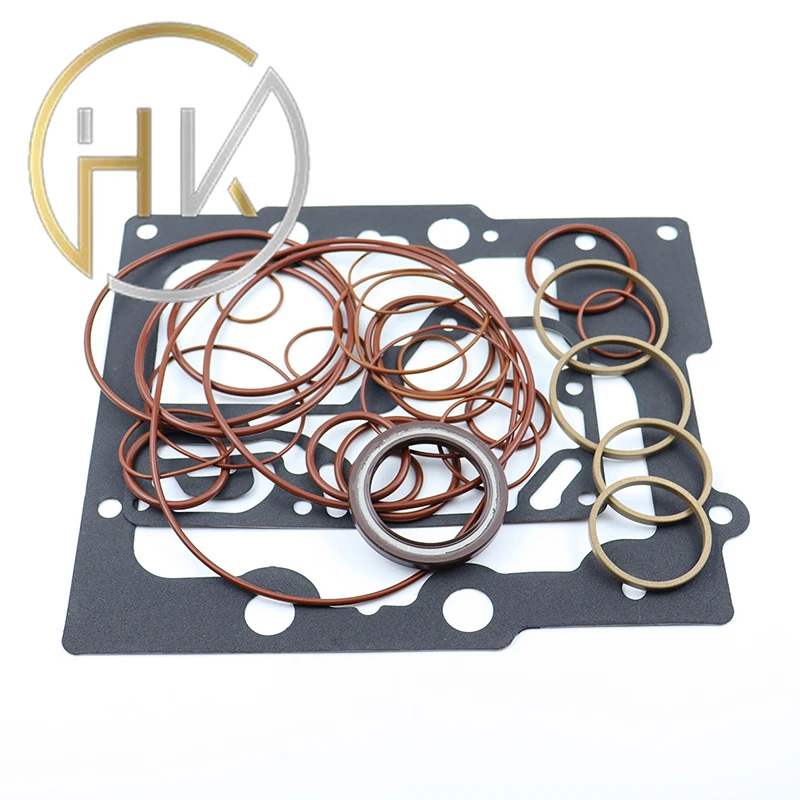

When it comes to machinery and equipment, the importance of various components cannot be overstated. One such critical component is the oil seal, specifically the 40x55x8 oil seal. This article delves into the specifications, applications, and importance of oil seals, with a particular focus on this 40mm x 55mm x 8mm model.

What is an Oil Seal?

An oil seal, also known as a grease seal or a differential seal, is a type of mechanical seal that prevents lubricant leakage from machinery and prevents the entry of contaminants. Made from a variety of materials, including rubber, polyacrylate, and other polymers, oil seals are essential for maintaining the integrity of machinery, ensuring optimal performance and longevity.

Specifications of the 40x55x8 Oil Seal

The designation 40x55x8 refers to the oil seal's dimensions it has an outer diameter of 55mm, an inner diameter of 40mm, and a width of 8mm. The figures indicate a sealing ring that is designed to fit snugly into specific applications, providing an effective barrier against oil leakage. Moreover, the % sign typically represents a specific tolerance level of the seal’s internal design or an essential feature relevant to its installation or usage.

The choice of material in the 40x55x8 oil seal greatly influences its performance. Common materials used include NBR (Nitrile Butadiene Rubber), which offers excellent resistance to oil and wear, and FKM (Fluoroelastomer), known for its thermal stability and chemical resistance.

Applications of the 40x55x8 Oil Seal

40x55x8 oil seal

The 40x55x8 oil seal is ubiquitous across numerous industries. It is widely used in automotive applications, such as in engine components, gearboxes, and wheel hubs, where it plays a crucial role in preventing oil loss and protecting sensitive parts from contaminants.

In industrial machinery, oil seals are vital in pumps, compressors, and hydraulic equipment. They ensure efficient operation by sealing lubricants inside the machinery, thus minimizing wear and tear on the moving parts. Furthermore, they help improve energy efficiency by reducing friction and maintaining system pressure.

Importance of the Oil Seal

The significance of oil seals, particularly the 40x55x8 model, cannot be overstated. They are a cost-effective solution to prolonging the lifespan of machinery. By preventing leaks, oil seals help reduce downtime and maintenance costs associated with oil loss and contamination.

Moreover, effective sealing contributes to safety. For example, in automotive applications, a failure of oil seals could lead to severe engine damage, resulting in costly repairs and potentially hazardous situations.

Conclusion

The 40x55x8 oil seal is an essential component in many applications, ensuring peak performance and reliability in machinery and vehicles. Understanding its specifications, applications, and benefits can help users make informed decisions when selecting components for their systems. Proper installation and maintenance of such seals can lead to enhanced durability and efficiency, providing a significant return on investment in the long run. Whether in automotive, industrial, or other settings, the oil seal plays a pivotal role in safeguarding machinery and ensuring smooth operations.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories