Dec . 04, 2024 09:18 Back to list

40x52x7 oil seal

Understanding the 40x52x7 Oil Seal Essential Knowledge for Rotational Equipment

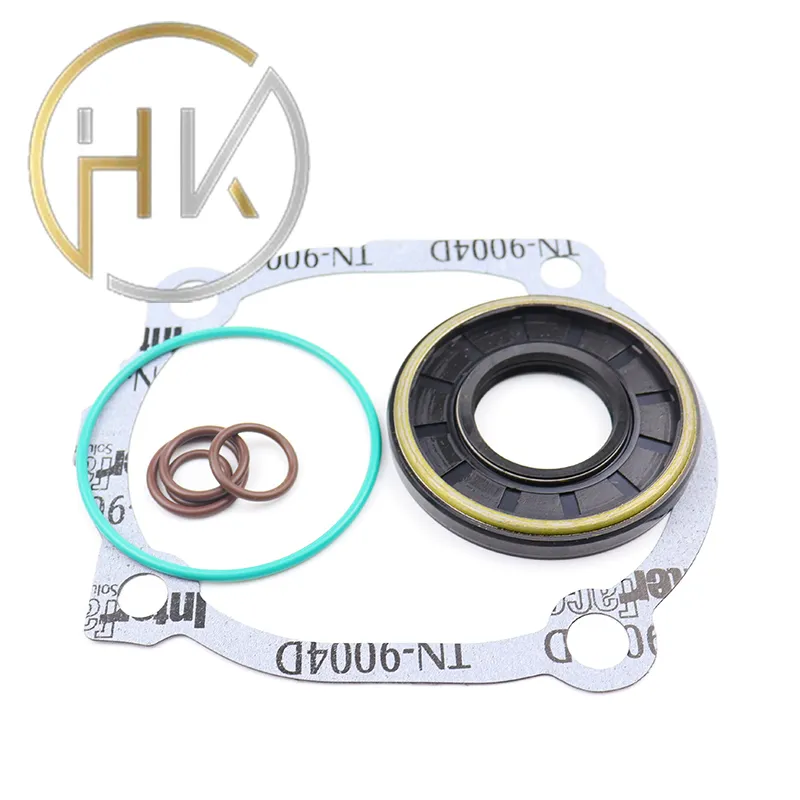

In the world of machinery and engineering, maintaining operational efficiency is of paramount importance. One key component that plays a significant role in ensuring smooth operation is the oil seal. Specifically, the 40x52x7 oil seal is a widely used part across various industries. This article aims to provide an in-depth understanding of its specifications, applications, maintenance, and importance in machinery.

Specifications of 40x52x7 Oil Seal

The designation 40x52x7 refers to the dimensions of the oil seal. In this designation

- 40 represents the inner diameter of the seal in millimeters. - 52 indicates the outer diameter of the seal in millimeters. - 7 signifies the thickness of the seal in millimeters.

Oil seals are typically made from materials such as rubber, polymer, or other sealant compounds, which ensure flexibility, durability, and resistance to wear and tear. The design of the 40x52x7 oil seal includes a lip that provides a tight barrier against oil leakage, contributing to the overall reliability of the machinery.

Applications Across Industries

The 40x52x7 oil seal is particularly versatile and finds applications in a diverse range of fields

1. Automotive Industry This oil seal is commonly used in vehicles, particularly in engines and transmissions, to prevent oil leaks that could lead to substantial mechanical failure.

2. Industrial Equipment Many machines in manufacturing plants utilize the 40x52x7 oil seal to ensure that lubricants stay contained within gearboxes or hydraulic systems, optimizing performance.

3. Agricultural Machinery Tractors and other farming equipment often rely on this type of oil seal to protect their internal components from contamination.

4. Home Appliances Even everyday household appliances, such as washing machines and dishwashers, utilize oil seals to prevent failures and increase longevity.

Importance in Machinery

40x52x7 oil seal

The proper functionality of the 40x52x7 oil seal is critical for machinery performance. Here are some of the reasons why

- Prevents Oil Leakage One of the primary functions of an oil seal is to prevent lubricating oil from leaking out of the machinery. By maintaining a sealed environment, the oil can continue to lubricate moving parts, reducing friction and wear.

- Protects Against Contaminants The oil seal acts as a barrier, preventing dirt, dust, and other contaminants from entering the system. This protection is crucial for maintaining oil purity and, consequently, machinery effectiveness.

- Enhances Equipment Lifespan By preventing leaks and keeping contaminants at bay, the oil seal contributes significantly to the overall longevity of machinery. Regular maintenance and replacement of oil seals can lead to fewer breakdowns and decreased repair costs.

Maintenance and Replacement

To ensure the continued effectiveness of the 40x52x7 oil seal, regular inspections are necessary. Signs that an oil seal may need to be replaced include

- Visible leaks around the seal If oil is seeping from around the edges of the seal, it should be addressed immediately.

- Engine overheating or inefficiencies This could indicate insufficient lubrication due to a failing oil seal.

- Excessive noise from machinery Unusual sounds might suggest that parts are not being adequately lubricated.

When replacing an oil seal, it is essential to choose the correct size and material to match the application requirements. Proper installation techniques should be employed to avoid damaging the seal during the process.

Conclusion

In conclusion, the 40x52x7 oil seal is a critical component in modern machinery that offers significant contributions to performance and longevity. Understanding its specifications, applications, and maintenance requirements can help ensure that equipment operates efficiently and reliably. By prioritizing the health of oil seals, industries can reduce costs, minimize downtime, and enhance the reliability of their machines. Whether in automotive applications, industrial settings, or home appliances, the role of the oil seal cannot be underestimated. Regular maintenance and timely replacement are key to unlocking the full potential of machinery equipped with this essential component.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories