Nov . 20, 2024 04:31 Back to list

40 80 10 oil seal

Understanding the 40% 80% 10% Oil Seal A Comprehensive Overview

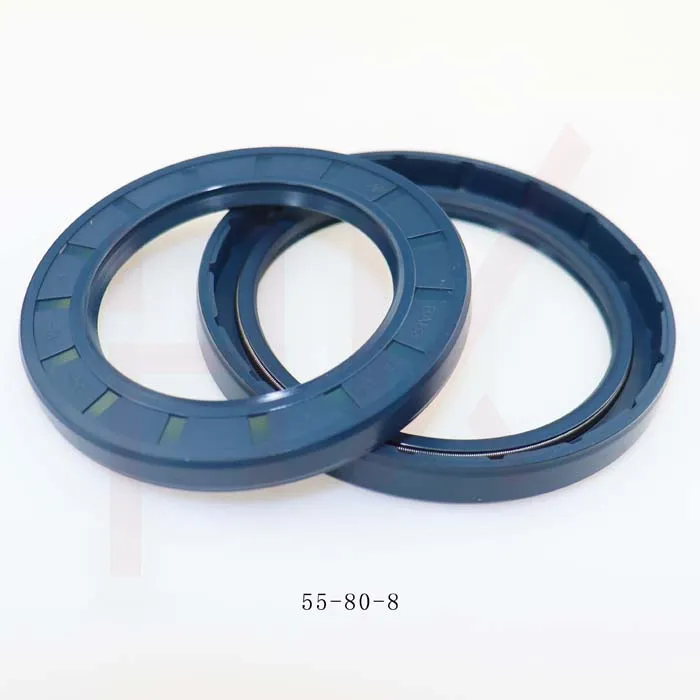

Oil seals play a crucial role in various mechanical systems, providing essential protection against contaminants and retaining lubrication. Among the various specifications of oil seals, the 40% 80% 10% oil seal stands out due to its specific composition and applications.

Understanding the 40% 80% 10% Oil Seal A Comprehensive Overview

The second figure, 80%, might represent the level of flexibility or elasticity the seal maintains while ensuring a robust sealing performance. Flexibility is essential because it allows the oil seal to conform to the surfaces it is sealing, ensuring a tight fit and minimizing the risk of leaks. This aspect is particularly important in rotary applications where dynamic sealing is required, as the oil seal must accommodate movement without losing its effectiveness.

40 80 10 oil seal

The final number, 10%, could signify the proportion of additives or fillers included in the oil seal's formulation. These additives can enhance various properties of the oil seal, such as improving wear resistance, increasing thermal stability, or providing additional protection against oxidation. Understanding this composition allows manufacturers to tailor oil seals for specific applications, ensuring optimal performance and longevity.

In practical applications, the 40% 80% 10% oil seal can be found in various industries, including automotive, aerospace, and manufacturing. For instance, in vehicles, these seals prevent oil leaks in engine components, ensuring efficient operation and preventing contamination of the engine oil. In industrial machinery, they help maintain the integrity of lubrication systems, reducing friction and wear, thereby extending equipment life.

In conclusion, the 40% 80% 10% oil seal encapsulates a strategic blend of materials designed for specific performance criteria. Understanding its composition and function can help engineers and technicians select the appropriate seals for their equipment, ensuring reliability and efficiency in numerous applications. With their critical role in maintenance and performance, oil seals remain an indispensable aspect of engineering and manufacturing processes.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories