Dec . 17, 2024 17:03 Back to list

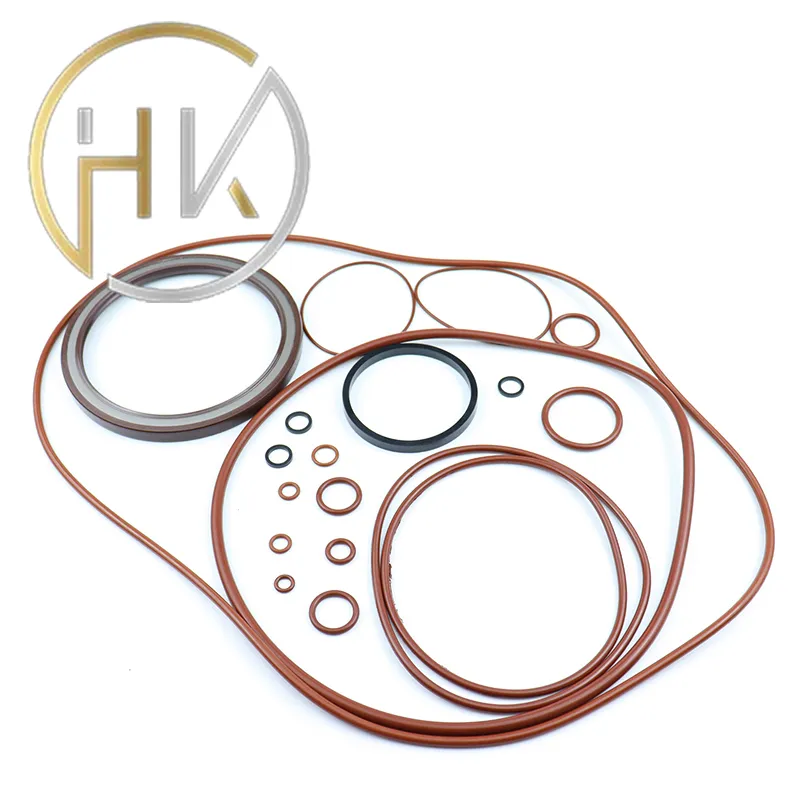

3 inch bore hydraulic cylinder seal kit

Understanding the 3-Inch Bore Hydraulic Cylinder Seal Kit

Hydraulic cylinders are an essential component in many industrial and construction applications, serving to convert hydraulic energy into mechanical energy. They function through the movement of a piston, which is powered by stored hydraulic fluid. A pivotal part of this operation is the seal kit, particularly for a 3-inch bore hydraulic cylinder. This article delves into the significance of seal kits, their components, and tips for maintenance and replacement.

The Importance of Seal Kits

In a hydraulic cylinder, the seal kit is crucial for preventing hydraulic fluid from leaking out and ensuring that the cylinder operates efficiently. A leak could lead to a decrease in performance, increased wear and tear, and possible damage to the system. Inadvertent leakage not only compromises the system but also poses environmental concerns, as hydraulic fluids can be harmful. Therefore, a well-functioning seal kit is vital for the longevity and reliability of hydraulic cylinders.

Components of a 3-Inch Bore Hydraulic Cylinder Seal Kit

A seal kit typically includes various types of seals, each serving a specific purpose

1. Piston Seals These seals are located on the piston itself and are responsible for maintaining pressure within the cylinder. A proper piston seal prevents hydraulic fluid from leaking past the piston, ensuring maximum force generation with minimal energy loss.

2. Rod Seals Positioned on the rod that extends from the cylinder, rod seals keep hydraulic fluid from leaking out of the cylinder when the rod is actuated. They also protect the internal components of the cylinder from contaminants in the environment.

3. Backup Rings These are often used with piston and rod seals to prevent extrusion under high-pressure conditions. They provide additional support and extend the life of the primary seal.

4. Wipers These seals are not just important for lubrication but also serve to keep contaminants like dust and dirt out of the cylinder. Wipers play a critical role in ensuring that the hydraulic system remains clean and operational.

3 inch bore hydraulic cylinder seal kit

Maintenance and Replacement

To ensure optimal performance, regular maintenance and timely replacement of the seal kit are essential. Here are some tips

1. Regular Inspection Inspections should be scheduled regularly to detect any signs of wear or damage. Look for signs such as leaking fluid, which can indicate that a seal is failing.

2. Contaminant Control Keeping contaminants out of the hydraulic system is crucial. Always use high-quality hydraulic fluids and ensure that the environment around the equipment is clean.

3. Replacement Timelines While there is no one-size-fits-all timeline for the replacement of seals, a general guideline is to replace seals every few years, depending on usage and operating conditions.

4. Proper Installation If you're replacing a seal kit, ensure it is installed correctly. Misalignment or improper installation can lead to early seal failure.

5. Consultation with Experts If you are uncertain about the condition of your seals or the replacement process, consulting with a hydraulic specialist can save time, money, and prevent further damage.

Conclusion

A 3-inch bore hydraulic cylinder seal kit is a vital assembly that ensures the efficient operation of hydraulic systems. By understanding the components of a seal kit and maintaining them properly, operators can enhance the performance and lifespan of their hydraulic cylinders. Regular monitoring and timely replacement of seals not only prevent leakage and contamination but also foster a safer work environment. Investing in high-quality seals and following best practices for maintenance will ultimately result in improved productivity and reduced operational costs. Therefore, take the time to understand your hydraulic cylinder's needs, and prioritize the integrity of its seals.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories