Dec . 12, 2024 10:01 Back to list

38x52x7 oil seal

Understanding the 38x52x7 Oil Seal Usage, Applications, and Benefits

In the world of mechanical engineering and automotive applications, oil seals play a crucial role in maintaining the integrity of machinery and ensuring optimal performance. Among various sizes and types of oil seals, the 38x52x7 oil seal has gained prominence due to its specific dimensions and wide range of applications. In this article, we will delve into the specifications, uses, and benefits of the 38x52x7 oil seal.

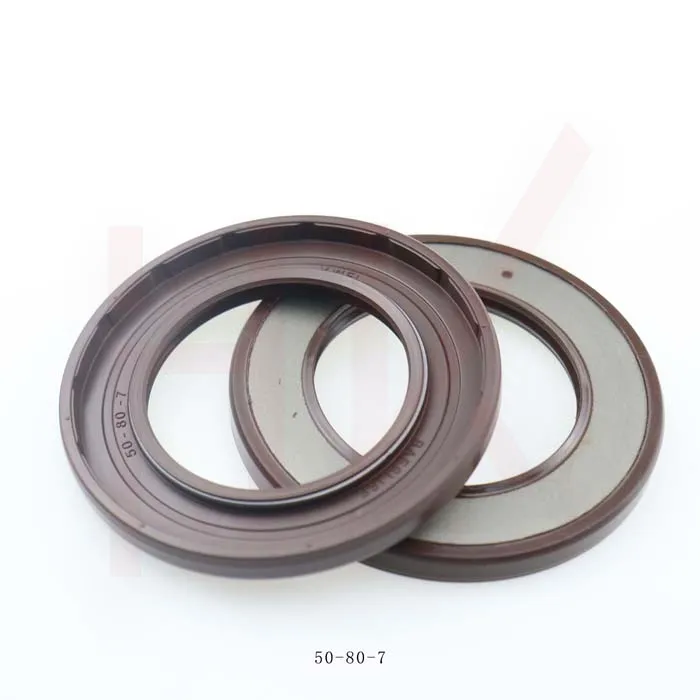

Specifications of the 38x52x7 Oil Seal

The code 38x52x7 refers to the dimensions of the oil seal. Specifically, it indicates that the outer diameter is 52 mm, the inner diameter is 38 mm, and its thickness is 7 mm. These measurements are essential to ensure a proper fit in the equipment it is intended for. Oil seals are generally designed to prevent the leakage of lubricants and keep contaminants out; thus, the correct dimensions are pivotal in achieving a reliable seal.

The material composition of the 38x52x7 oil seal is typically made from rubber or other elastomers, often reinforced with fabric for added strength and durability. The choice of material can significantly influence the seal's performance, particularly against abrasion and thermal conditions, thereby affecting the overall longevity of the equipment.

Common Applications

The versatility of the 38x52x7 oil seal allows it to be utilized in various applications

. Predominantly, it is found in automotive engines, gearboxes, and hydraulic cylinders, among other machinery. In engines, oil seals are crucial in preventing oil leakage, which can lead to severe engine damage and costly repairs. Furthermore, they help in maintaining the desired pressure levels within the engine components.38x52x7 oil seal

In hydraulic systems, the 38x52x7 oil seal provides essential sealing, ensuring that hydraulic fluid remains contained within the system. This containment minimizes the risk of leaks, which can not only affect the efficiency of the machinery but also compromise safety. In industrial machinery, these seals are used in conjunction with rotating shafts to prevent contamination of lubricants, thereby extending the lifespan of the equipment.

Advantages of Using 38x52x7 Oil Seals

Using the 38x52x7 oil seal comes with several advantages. Firstly, its design facilitates effective sealing under a variety of working conditions, including pressure fluctuations and temperature changes. This adaptability ensures a long-lasting performance, reducing the need for frequent replacements.

Additionally, the use of high-quality materials in manufacturing these seals contributes to their resistance to wear and tear, further enhancing their reliability. This durability translates to minimized downtime for machinery, which is crucial for industries that rely on continuous operation.

Lastly, the economic aspect of utilizing 38x52x7 oil seals cannot be overlooked. By preventing lubricant leakage and reducing contamination, these seals lower maintenance costs and prolong the life of machinery. For businesses, this can result in significant savings over time.

Conclusion

In summary, the 38x52x7 oil seal serves as an indispensable component in various applications, particularly in automotive and industrial machinery. Its specific dimensions, coupled with high-quality materials, provide effective sealing that extends equipment life and enhances performance. For any mechanical engineer or maintenance professional, understanding and utilizing the right oil seal is fundamental to ensuring smooth operations and reliability in machinery. As technology advances, further improvements in seal design and materials may continue to enhance the efficacy of these essential components in the years to come.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories