Dec . 29, 2024 22:33 Back to list

35x47x7 Oil Seal Specifications and Applications for Enhanced Sealing Performance

Understanding the 35x47x7 Oil Seal Specifications, Applications, and Benefits

When it comes to mechanical systems, having the right components is crucial for efficient operation and longevity. One such component that often plays a vital role in various machines is the oil seal. Among the many different sizes and types of oil seals, the 35x47x7 oil seal stands out. This article will delve into the specifications, applications, and benefits of the 35x47x7 oil seal.

Specifications

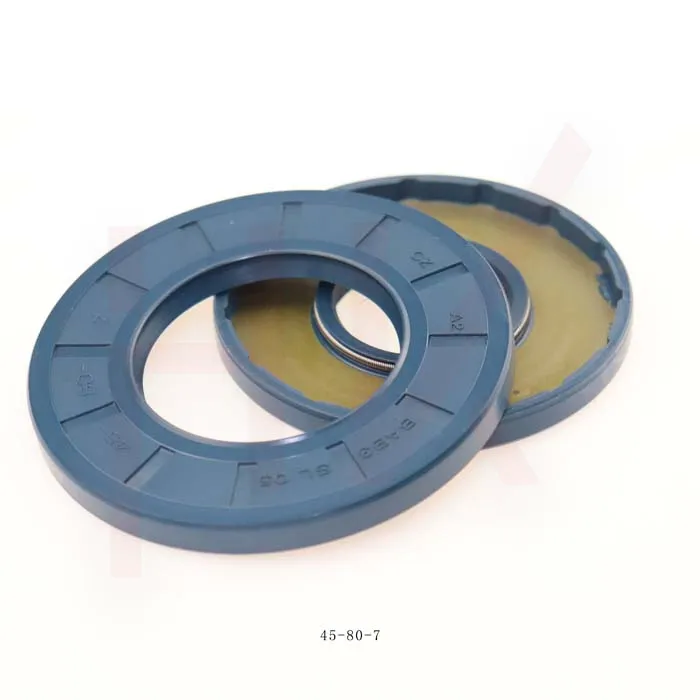

The numbers in the designation 35x47x7 refer to the dimensions of the oil seal a 35mm inner diameter, a 47mm outer diameter, and a thickness of 7mm. These measurements are essential as they determine the seal's fit and function within a mechanical assembly. The oil seal is typically made from elastomeric materials, which provide excellent flexibility and durability, crucial for maintaining a tight seal against various fluids, including oil. Common materials include nitrile rubber (NBR), fluorocarbon rubber (FKM), and silicone, each offering different levels of resistance to temperature, chemicals, and abrasions.

Applications

The 35x47x7 oil seal is commonly used in various applications across different industries. These seals are particularly prevalent in the automotive sector, where they help prevent the leakage of oil from engine components such as crankshafts and camshafts. This is vital not only for maintaining the efficiency of the engine but also for preventing oil spills that can lead to environmental hazards.

In addition to automotive applications, the 35x47x7 oil seal is utilized in machinery and equipment used in construction, manufacturing, and agricultural sectors. For instance, it is often found in hydraulic systems, where it helps maintain pressure and prevent fluid leaks, ensuring smooth machine operation. Moreover, these seals are also used in gearboxes and transmissions, where they help manage lubricant retention.

Benefits

35x47x7 oil seal

The primary benefit of using a 35x47x7 oil seal is its ability to effectively retain lubricants within machinery while preventing contaminants from entering. This sealing action not only extends the lifespan of mechanical components but also enhances overall performance. Here are some specific benefits of the 35x47x7 oil seal

1. Leak Prevention One of the most critical functions of the oil seal is to prevent leaks, which can lead to decreased efficiency and potential damage to machinery. The precise dimensions of the 35x47x7 oil seal ensure a tight fit, thereby minimizing the risk of leaks.

2. Improved Equipment Longevity By keeping lubricants in and contaminants out, the oil seal helps prolong the life of machinery and equipment. This is especially important in high-performance applications where wear and tear can significantly impact functionality.

3. Cost-Effectiveness The durability of the materials used in oil seals means that they often require less frequent replacement compared to lower-quality alternatives. This translates to cost savings over time, as less downtime is needed for maintenance and repairs.

4. Versatility The 35x47x7 oil seal can be used in various applications, making it a versatile choice for manufacturers and mechanics alike. Its ability to adapt to different environments, whether they involve high temperatures or exposure to chemicals, only adds to its appeal.

Conclusion

In summary, the 35x47x7 oil seal is a critical component in many mechanical systems, with significant applications ranging from automotive to industrial machinery. Its specific dimensions, made from durable materials, ensure reliability and effective sealing action. By preventing leaks, enhancing equipment lifespan, and providing versatility across various fields, the 35x47x7 oil seal proves to be an essential part of mechanical design, ensuring systems operate smoothly and efficiently. Whether you are a manufacturer, mechanic, or hobbyist, understanding the importance of the 35x47x7 oil seal can help you make informed decisions that lead to better machinery performance and longevity.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories