Nov . 12, 2024 03:22 Back to list

31x43x10 5 oil seal

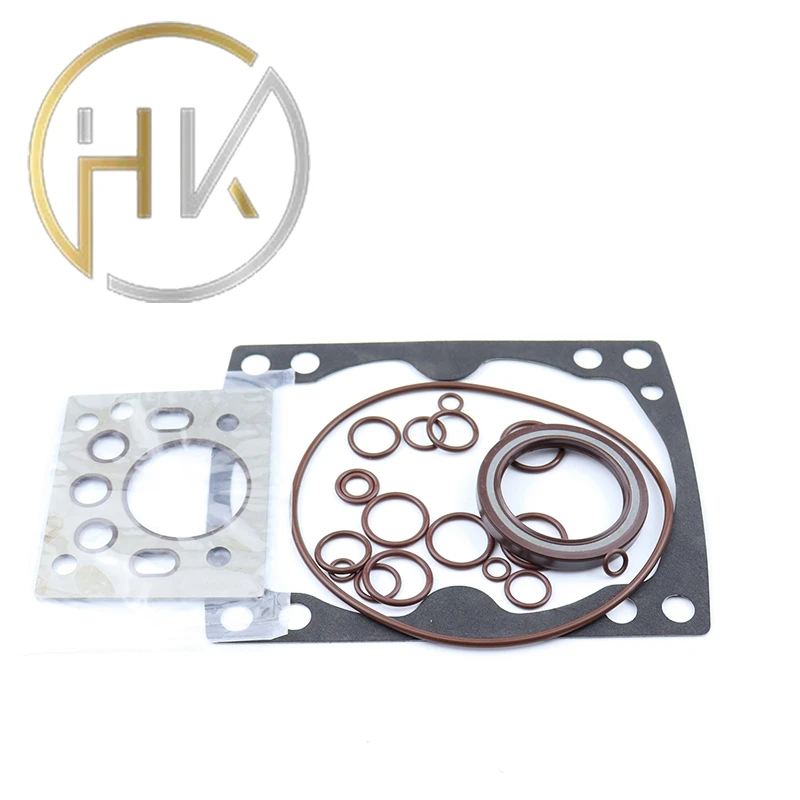

Understanding the 31x43x10 5 Oil Seal Importance, Applications, and Installation

In the world of mechanical engineering, oil seals play a critical role in ensuring the smooth operation of machinery. Among the various types of oil seals available, the 31x43x10 oil seal stands out due to its specific dimensions and unique features. This article will delve into the significance of this particular oil seal, its applications, and how to properly install it for optimal performance.

What is an Oil Seal?

An oil seal, also known as a radial sealing element or shaft seal, is a device used to prevent the leakage of lubricants while keeping dirt and contaminants out of rotating or sliding components. The basic function of an oil seal is to retain oil or grease within a given area while preventing external substances from entering, which could lead to wear and tear and ultimately mechanical failure.

Dimensions Explained 31x43x10

The dimensions of an oil seal are critical in determining its compatibility with specific applications. The designation 31x43x10 refers to the oil seal's inner diameter (31mm), outer diameter (43mm), and thickness (10mm). These precise measurements are designed to fit particular machinery or equipment. Ensuring that you select the correct size is essential for preventing leaks and maintaining the efficiency of your equipment.

The 205% Specification

The 205% mentioned in the designation usually refers to the material or design variation, which could indicate specific applications or enhanced features such as better temperature tolerance or chemical resistance. Understanding these specifications is vital when choosing an oil seal, as they affect performance and durability.

Applications of the 31x43x10 Oil Seal

The 31x43x10 oil seal is commonly used in various applications across different industries, including

1. Automotive Industry Oil seals are integral in engines, transmissions, and differentials to prevent oil leakage and ensure proper lubrication. 2. Industrial Machinery In machinery such as pumps and compressors, oil seals are crucial for maintaining the integrity of lubrication systems.

3. Agricultural Equipment Equipment like tractors and harvesters often rely on oil seals to protect their operational components from contaminants.

31x43x10 5 oil seal

4. Marine Applications For boats and ships, oil seals protect sensitive components from saltwater intrusion, prolonging the lifespan of equipment.

Importance of Regular Maintenance

Regular inspection and maintenance of oil seals, including the 31x43x10 variant, are vital for ensuring their longevity and effectiveness. Over time, seals can become brittle or worn due to factors like temperature fluctuations, exposure to chemicals, or physical abrasion. A thorough inspection should be part of any equipment maintenance program, as early detection of wear can prevent larger issues from developing, ultimately saving time and costs associated with equipment downtime.

Installation Guidelines

Proper installation is critical to the efficacy of an oil seal. Here are some guidelines to ensure successful installation

1. Preparation Ensure that the housing and the shaft where the seal will be installed are clean and free from burrs or debris.

2. Lubrication Applying a thin film of lubricant on the lip of the seal can help facilitate installation and enhance its performance.

3. Alignment Ensure that the seal is installed straight to avoid distortion which may result in leaks.

4. Use of Appropriate Tools Employ specialized tools for sealing to ensure even pressure without damaging the seal during installation.

5. Testing After installation, run the machinery under normal operating conditions to check for any leaks or operational issues.

Conclusion

The 31x43x10 oil seal is a significant component in various industrial and mechanical applications. Understanding its dimensions, specifications, and proper installation methods can help maintain machinery efficiency and integrity. By recognizing the importance of oil seals and incorporating regular maintenance into operational procedures, businesses can enhance productivity and reduce the risk of failure in their equipment.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories