Sep . 21, 2024 23:14 Back to list

30x52x7 seal

Understanding the 30x52x7% Seal A Comprehensive Guide

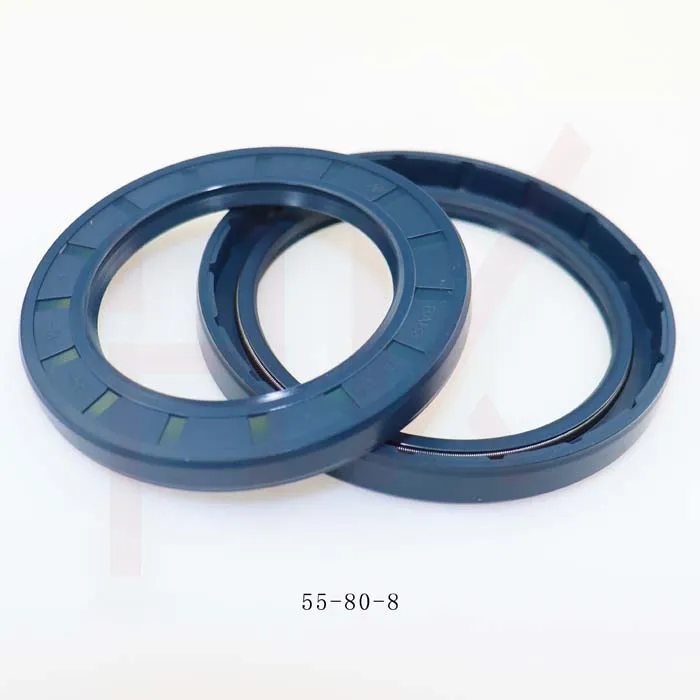

When it comes to machinery and manufacturing, seals play a crucial role in ensuring the efficiency and longevity of equipment. Among the various types of seals available, the 30x52x7% seal is particularly noteworthy due to its unique dimensions and applications. This article will delve into the significance of this type of seal, its design specifications, and common uses in various industries.

What is a 30x52x7% Seal?

The designation 30x52x7% refers to the seal's dimensions, specifically its inner diameter, outer diameter, and thickness. The first number, 30, indicates the inner diameter of the seal in millimeters (mm), while the second number, 52, represents the outer diameter. The thickness, denoted by 7, indicates the seal's cross-section. The percent symbol suggests a specific tolerance or compression aspect related to the seal's material properties, which is crucial for its functioning.

Design and Material Considerations

The construction of a 30x52x7% seal may vary based on its intended use. Common materials include rubber, silicon, and polyurethane, each offering different levels of flexibility, durability, and resistance to various chemicals and temperatures. For instance, rubber seals are often used in general applications because of their cost-effectiveness and good sealing properties, whereas silicone seals might be preferred for high-temperature applications due to their thermal resistance.

The design also incorporates various features, such as lip configurations, which help promote effective sealing. The more precise these features are, the better the seal can handle pressure differences and prevent leakage. Additionally, many modern seals come with added features, such as specialized coatings to enhance performance and resistance to wear.

30x52x7 seal

Applications Across Industries

The versatility of the 30x52x7% seal allows it to be employed in multiple industries. In the automotive sector, these seals are frequently used in engines, transmissions, and differential assemblies. They serve as barriers, preventing oil and other fluids from leaking while also blocking contaminants from entering sensitive components.

In industrial machinery, such seals are critical for hydraulic and pneumatic applications, where they maintain pressure and prevent fluid loss. Similarly, in the food and beverage industry, hygienic seals are necessary to meet stringent health regulations while ensuring efficient operation.

Moreover, these seals are prevalent in household appliances, ensuring that washing machines, refrigerators, and dishwashers function smoothly without any leaks, which could lead to damage or inefficiencies.

Conclusion

The 30x52x7% seal is a vital component across various sectors, providing essential sealing solutions that enhance operational efficiency and equipment longevity. Understanding its dimensions, materials, and applications enables engineers and technicians to select the right seal for their specific requirements, thereby optimizing performance while minimizing maintenance costs. As technology continues to advance, the innovation surrounding seals will undoubtedly evolve, leading to even more robust and efficient solutions for the industries that rely on them.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories