Nov . 28, 2024 04:49 Back to list

30x47mm Oil Seal Specifications and Applications for Automotive and Industrial Use

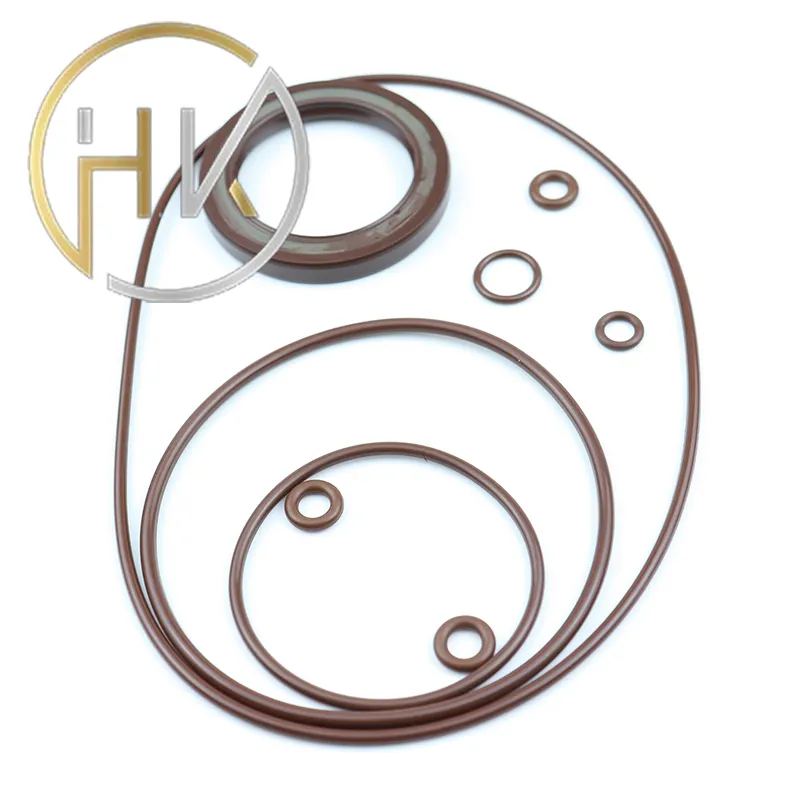

The Importance of the 30x47x7mm Oil Seal in Mechanical Applications

In the realm of mechanical engineering and maintenance, the effective sealing of fluids and gases is crucial for the performance and longevity of machinery. Among the various components designed for this purpose, the 30x47x7 oil seal stands out due to its versatile applications, reliability, and essential role in ensuring the smooth operation of mechanical systems.

Understanding Oil Seals

Oil seals, also known as rotary shaft seals or lip seals, are designed to prevent the leakage of lubricants while keeping contaminants out. They are essential in rotary applications where shafts rotate within a housing. The design typically consists of a flexible lip that contacts the shaft, forming a barrier that minimizes leakage. The specifications of the 30x47x7 oil seal indicate its dimensions a outer diameter of 30mm, an inner diameter of 47mm, and a thickness of 7mm. These measurements make it suitable for various applications across industries, including automotive, industrial machinery, and hydraulic systems.

Applications of the 30x47x7 Oil Seal

The 30x47x7 oil seal is commonly used in numerous applications

. In the automotive sector, it is often found in engine components, gearbox assemblies, and differentials. The seal prevents oil from leaking out of the engine while stopping dirt and debris from entering, maintaining the cleanliness and efficiency of the engine.In industrial machinery, the 30x47x7 oil seal serves a critical role in hydraulic cylinders, compressors, and pumping systems. Here, the seal not only maintains the integrity of the lubricant but also ensures that hydraulic fluid does not escape, which is vital for maintaining pressure and operational efficiency. Similarly, in manufacturing equipment, the oil seal helps extend the life of machines by reducing wear caused by contamination and lubricant loss.

30x47x7 oil seal

Benefits of Using the 30x47x7 Oil Seal

One of the primary benefits of using the 30x47x7 oil seal is its ability to withstand extreme conditions. Constructed from high-quality materials such as rubber, nitrile, or fluorinated elastomers, these seals exhibit excellent resistance to various fluids, chemicals, and temperatures. As a result, they can operate effectively in both low and high-temperature environments, making them suitable for diverse applications.

Moreover, the design also allows for easy installation and replacement. This is especially advantageous in maintenance situations where downtime must be minimized. The availability of standard dimensions, such as the 30x47x7 size, simplifies stock management for repair facilities and ensures quick access to replacement parts.

Challenges and Considerations

Despite their advantages, using oil seals is not without challenges. One of the common issues faced is deterioration due to improper installation or exposure to incompatible fluids. It is crucial to ensure that the seal is installed correctly and that it is compatible with the specific application environment. Regular inspection and timely replacement of worn seals can help mitigate potential leaks and maintain equipment efficiency.

Conclusion

In conclusion, the 30x47x7 oil seal is a vital component in many mechanical systems across various industries. Its ability to prevent leaks and protect against contamination makes it indispensable in ensuring the reliable operation of machinery. With benefits such as robust design, versatility, and ease of installation, the 30x47x7 oil seal is indeed an essential part of modern engineering solutions. As industries continue to evolve and demand more efficient and reliable machinery, the role of oil seals will remain critical in achieving these goals. Proper selection, installation, and maintenance of oil seals will not only enhance operational efficiency but also contribute to the longer life of machinery, thereby providing significant economic benefits.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories