Dec . 03, 2024 14:32 Back to list

2 inch Hydraulic Cylinder Seal Kit for Optimal Performance and Durability

Understanding the 2-Inch Hydraulic Cylinder Seal Kit A Comprehensive Guide

Hydraulic cylinders are essential components in various machinery and applications, providing the necessary force for lifting, pushing, or pulling. Central to their functionality is the hydraulic cylinder seal kit, which ensures that hydraulic fluid remains contained within the cylinder and prevents leaks that can lead to inefficient operation or even equipment failure. In this article, we will focus on the 2-inch hydraulic cylinder seal kit, exploring its components, importance, maintenance, and tips for selecting the right kit for your needs.

What is a Hydraulic Cylinder Seal Kit?

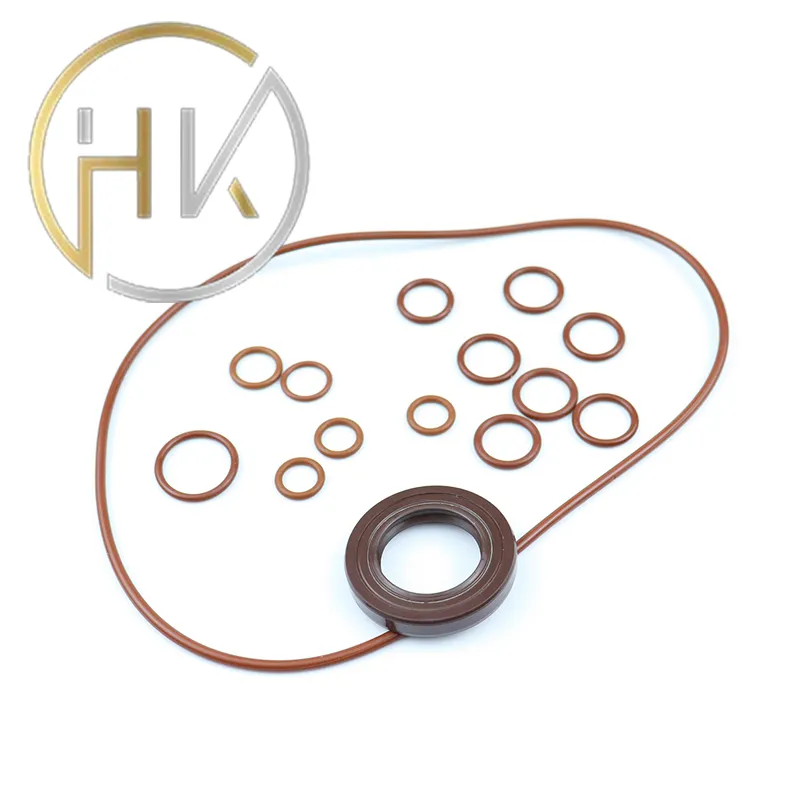

A hydraulic cylinder seal kit contains various seals and O-rings designed to fit a specific size of hydraulic cylinder, in this case, a 2-inch diameter cylinder. These seals are essential for maintaining the pressure within the hydraulic system by preventing fluid from leaking out. The kit usually includes items such as

- Piston Seals These create a sealing surface between the moving piston and the cylinder wall, ensuring that the hydraulic fluid can push the piston effectively. - Rod Seals These seals are located on the rod where it exits the cylinder, preventing fluid from leaking out of the cylinder as the rod extends and retracts. - Back-up Rings These rings provide additional support and help prevent seal extrusion under high pressure. - O-rings Used for various purposes, including sealing between components such as flanges and fittings.

Importance of Choosing the Right Seal Kit

The functionality of a hydraulic system heavily relies on the integrity of its seals

. Selecting an appropriate seal kit has several advantages1. Preventing Leaks A good seal kit prevents hydraulic fluid from escaping, which not only saves fluid but also ensures consistent pressure within the system. 2. Extending Equipment Life With proper sealing, wear and tear on the hydraulic cylinder can be minimized, leading to a longer lifespan for both the cylinder and the entire hydraulic system. 3. Maintaining Efficiency By ensuring that hydraulic pressure is maintained, the system operates smoothly, reducing the chances of breakdowns and improving overall efficiency. 4. Cost-Effectiveness Investing in a high-quality seal kit minimizes the risk of costly repairs and downtime that can arise from leaks or seal failures.

2 inch hydraulic cylinder seal kit

Maintenance Tips for Hydraulic Cylinder Seal Kits

Regular maintenance of hydraulic systems is crucial to ensure optimal performance and longevity. Here are a few tips for maintaining a 2-inch hydraulic cylinder and its seals

- Routine Inspections Regularly check for signs of wear or damage on seals, such as cracks, tears, or discoloration. Early detection can prevent leaks and further damages. - Cleanliness is Key Keep the hydraulic system clean. Contaminants can damage seals and lead to failure. Ensure that the area around the cylinder is free from dirt and debris. - Fluid Quality Use the correct type of hydraulic fluid as specified by the manufacturer. Contaminated or incorrect fluid can deteriorate seals faster than expected. - Monitor Performance Keep an eye on the performance of the hydraulic cylinder. Any unusual noises, decreased efficiency, or visible leaks should be addressed immediately.

Choosing the Right 2-Inch Hydraulic Cylinder Seal Kit

When selecting a seal kit for a 2-inch hydraulic cylinder, consider the following factors

1. Compatibility Ensure that the seal kit is specifically designed for your hydraulic cylinder's model and specifications. 2. Material Quality Look for high-quality materials, such as polyurethane or rubber compounds that can withstand the operating pressures and environments. 3. Supplier Reputation Purchase from reputable manufacturers or suppliers known for their quality products and excellent customer service.

Conclusion

The 2-inch hydraulic cylinder seal kit is a critical component in maintaining the functionality and efficiency of hydraulic systems. By understanding its role, the importance of proper maintenance, and how to select the right kit, operators can ensure their equipment runs smoothly, ultimately saving time and money in their operations. Regular inspections and the use of high-quality components are fundamental to achieving continued productivity and reliability in hydraulic applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories