Dec . 12, 2024 11:28 Back to list

25x35x7 oil seal

Understanding the 25x35x7 Oil Seal Importance and Applications

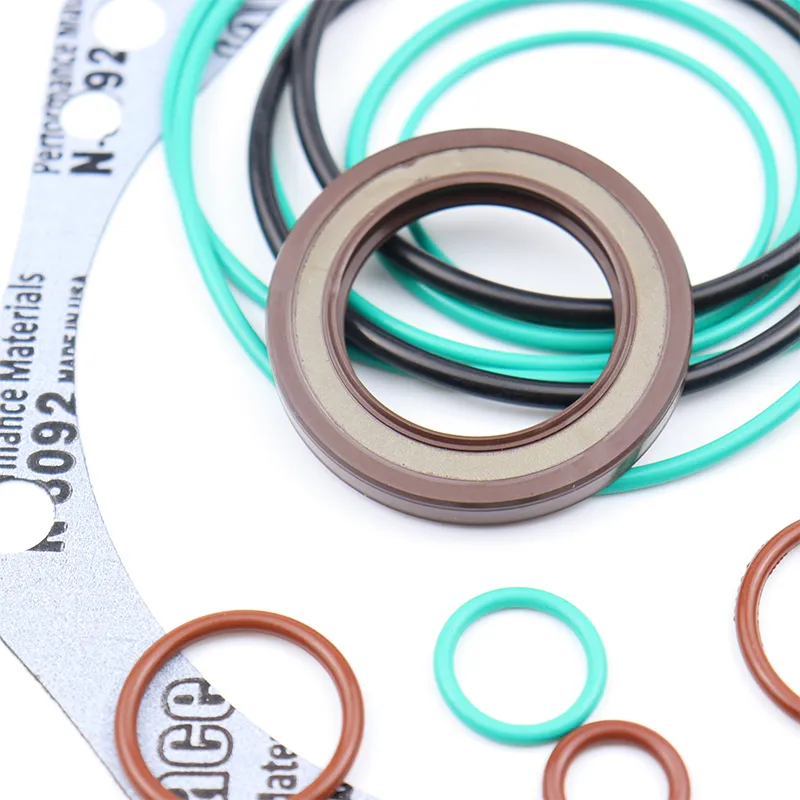

Oil seals are crucial components in various machinery and automotive systems, designed to prevent the leakage of lubricants and the ingress of contaminants. One such product that stands out is the 25x35x7 oil seal. This particular oil seal is characterized by its dimensions, with an outer diameter of 35 mm, an inner diameter of 25 mm, and a thickness of 7 mm. Let’s delve into the importance, features, applications, and maintenance of the 25x35x7 oil seal.

Importance of Oil Seals

The primary function of an oil seal is to maintain the integrity of lubricated areas by safeguarding against fluid leaks. They are essential for ensuring the longevity and efficient operation of machinery. By sealing off lubrication from contaminants such as dirt, dust, water, and other foreign materials, oil seals help maintain a clean and efficient lubrication environment. This contributes to reducing wear and tear, lowering the risk of operational failures, and ultimately enhancing the performance of machines.

Key Features

The 25x35x7 oil seal material is typically made of elastomeric compounds, such as nitrile rubber (NBR), which is known for its excellent resistance to petroleum-based oils and the ability to withstand varying temperatures. The design of the oil seal often includes a lip that contacts the shaft surface, creating a tight seal. This lip design is crucial as it ensures minimal friction while retaining the oil within the compartment it seals.

Applications

Given its dimensions and robust features, the 25x35x7 oil seal is used in various applications across different industries

1. Automotive Use In vehicles, oil seals are commonly used in engines, transmissions, and differentials. The 25x35x7 seal can be found in vehicles where it serves to prevent oil leaks around rotating shafts, ensuring that the lubricant stays where it should while protecting the internal components from contamination.

25x35x7 oil seal

2. Industrial Machinery In industries, the 25x35x7 oil seal can be utilized in hydraulic cylinders, pumps, and gearboxes. These seals help maintain the performance of critical machinery by ensuring that lubricants remain intact and contaminants are kept at bay.

3. Household Appliances Smaller variants of oil seals are often found in household appliances such as washing machines and refrigerators, where they prevent fluid leaks and ensure proper operation.

4. Agricultural Equipment Tractors and other agricultural machinery often use oil seals like the 25x35x7 to prevent leakage of lubricants in harsh working conditions, contributing to the reliability and efficiency of the equipment.

Maintenance and Replacement

To ensure the longevity of machinery and avoid costly repairs, regular inspection of oil seals is recommended. Signs of wear or damage, such as leaks or unusual noises, are indicators that the oil seal may need replacement. Replacing an oil seal can vary in complexity depending on its location within the machinery, but it is generally a straightforward process in most cases.

When replacing a 25x35x7 oil seal, it is essential to ensure that the correct tools are used and that the installation is done with precision to avoid compromising the seal. Lubrication of the sealing lip during installation can also help ensure a long-lasting and effective seal.

Conclusion

The 25x35x7 oil seal, while a small component in the grand scheme of machinery, plays a vital role in the proper functioning and maintenance of various systems. By preventing oil leaks and contamination, this oil seal helps ensure that equipment runs smoothly, efficiently, and for longer periods. Whether in automotive applications, industrial machinery, or household appliances, understanding the importance and function of the 25x35x7 oil seal can help operators and maintenance personnel keep their machines in optimal condition. Regular inspection and timely replacement are key to maximizing the lifespan and performance of both the oil seal and the equipment it serves.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories