Nov . 25, 2024 10:23 Back to list

Oil Seal Specifications for 25%, 40%, and 7% Applications in Industry

Understanding the Significance of the 25%-40%-7% Oil Seal in Mechanical Applications

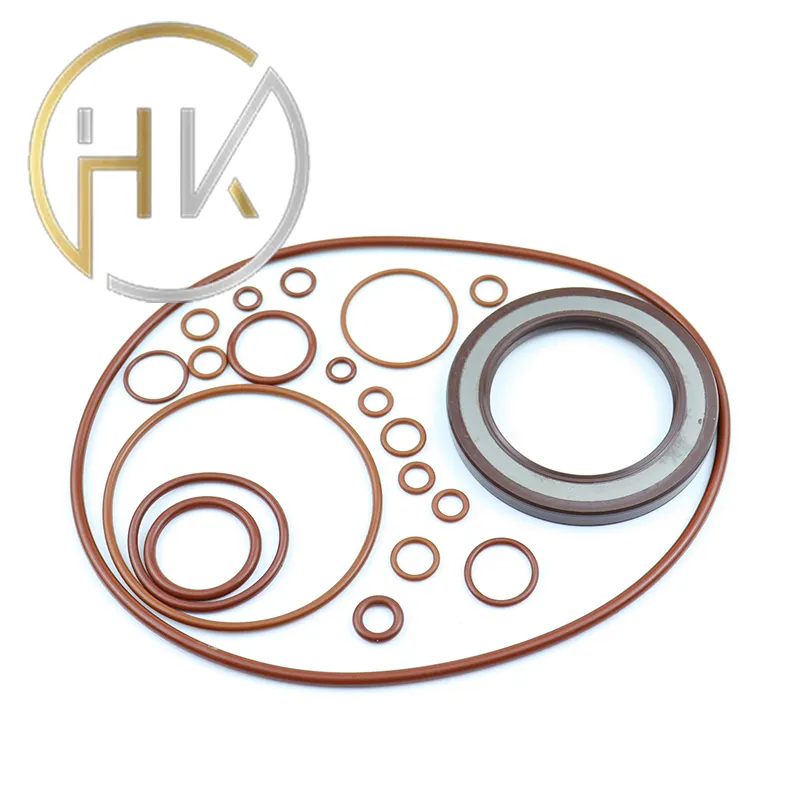

Oil seals play a vital role in the functioning and longevity of machinery by preventing the leakage of lubricants and protecting moving parts from external contaminants. Among the various types of oil seals, the 25%-40%-7% oil seal has garnered attention due to its specific design and functionality, along with the advantages it offers in diverse applications. This article delves into the significance, construction, and applications of the 25%-40%-7% oil seal.

Construction of the 25%-40%-7% Oil Seal

The nomenclature 25%-40%-7% indicates specific dimensions and tolerances critical for its fitting in mechanical systems. Typically, this refers to the seal's outer diameter, inner diameter, and the thickness of the seal. Each percentage corresponds to the proportion of the seal's components designed for optimum performance. The outer diameter provides the necessary interface to ensure a secure fit within the housing, while the inner diameter allows for a snug fit around the shaft, preventing fluid leakage.

The material used in manufacturing oil seals significantly affects their durability and effectiveness. Common materials include nitrile rubber, silicone, and fluorocarbon, each offering unique properties such as temperature resistance, chemical stability, and wear resistance. The choice of material allows the 25%-40%-7% oil seal to withstand varying environmental conditions, making it suitable for applications in automotive, aerospace, and industrial machinery.

Functionality

The primary function of the 25%-40%-7% oil seal is to create a barrier against oil leakage while keeping contaminants, like dust and moisture, at bay. This is achieved through a lip design that exerts pressure against the rotating shaft, effectively sealing the interface. A well-designed oil seal minimizes friction between moving components, which helps maintain efficiency and prolongs the life of the machinery.

25 40 7 oil seal

Moreover, the correct fit is essential for optimal sealing performance. If the seal is too tight or too loose, it can lead to premature wear or failure. This highlights the importance of precise measurements and the proper selection of the 25%-40%-7% seal when replacing worn components in machinery.

Applications

The versatility of the 25%-40%-7% oil seal makes it applicable across various industries. In automotive applications, it is commonly used in engines, transmissions, and differentials, where it prevents oil leaks that can lead to severe damage and reduced efficiency. The aerospace industry also employs oil seals to ensure the proper functioning of hydraulic systems and gearboxes, where maintaining pressure is critical.

In industrial settings, these seals are integral to maintaining equipment like pumps, compressors, and motors. The 25%-40%-7% oil seal contributes to operational efficiency by ensuring minimal maintenance is required. Manufacturing downtime due to seal failure can be costly; thus, implementing reliable oil seals significantly reduces the risk of equipment failure and enhances overall productivity.

Conclusion

In conclusion, the 25%-40%-7% oil seal is an indispensable component in various mechanical systems, providing crucial functions of sealing and protection. Its precise design, coupled with the appropriate materials, ensures optimal performance and longevity in numerous applications. By understanding the significance of this oil seal, engineers and technicians can make informed decisions when selecting components for their machinery, ultimately leading to enhanced efficiency and reduced maintenance costs. The continued evolution of oil seal technology will undoubtedly pave the way for even more reliable and efficient solutions in the future.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories