Dec . 16, 2024 02:36 Back to list

25 35 7 oil seal

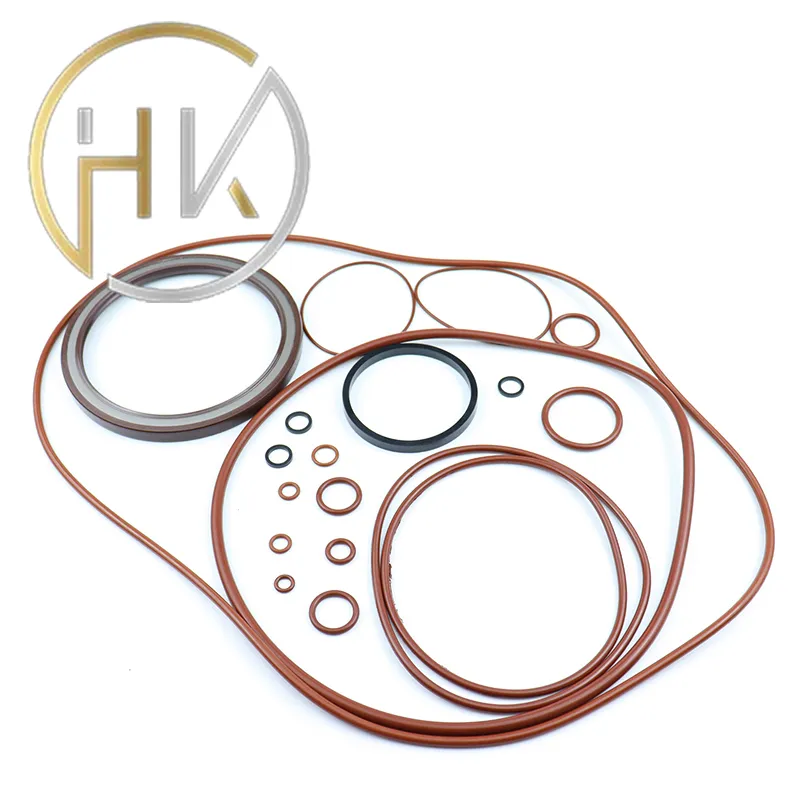

Understanding the Importance of the 25% 2035 7 Oil Seal in Industrial Applications

In the realm of industrial machinery and equipment, oil seals play a crucial role in ensuring optimal performance, longevity, and efficiency. Among various specifications, the 25% 2035 7 oil seal has garnered attention for its unique design and functional attributes. To appreciate its significance, it is essential to delve into the meaning of these numerical values and understand how they influence the oil seal's performance in different applications.

What Does 25% 2035 7 Mean?

The designation 25% 2035 7 typically refers to specific engineering parameters that define the oil seal’s characteristics. The 25% often indicates a level of elasticity or compression capability, which is critical for maintaining a tight seal against fluid leaks. The 2035 might specify the dimensions or compatibility with certain machinery standards, such as the outer diameter, inner diameter, or thickness. 7, in this context, may refer to the material grade or a design characteristic that enhances its utility in specific environments.

Understanding these parameters is vital for manufacturers and engineers as they select the appropriate oil seal for a specific application. This ensures that the seal will perform adequately under the operational conditions it faces.

Importance of Oil Seals in Machinery

Oil seals serve several critical functions in machinery. They prevent the leakage of lubricants, which is essential for maintaining the efficiency of moving parts. If lubricant escapes, friction increases, leading to wear and tear that can ultimately cause machinery to fail. Furthermore, oil seals protect against dirt, dust, and moisture, which can contaminate lubricants and damage internal components.

Moreover, oil seals are integral in enhancing the overall reliability of machinery. A well-functioning oil seal can contribute to reduced maintenance costs and prolonged equipment life. Given the significant role they play, ensuring that the right type of oil seal—like the 25% 2035 7—is used in machinery is of utmost importance.

Applications of the 25% 2035 7 Oil Seal

25 35 7 oil seal

The 25% 2035 7 oil seal finds applications across various industries, including automotive, manufacturing, and aerospace. In automotive contexts, these seals are commonly used in engines, transmissions, and axles. Their ability to withstand high temperatures and pressures makes them ideal for vehicles that operate under extreme conditions.

In manufacturing, oil seals are extensively used in pumps, compressors, and conveyor systems. The versatility of the 25% 2035 7 oil seal enables it to perform efficiently in both standard and challenging operational settings. It provides the necessary protection to ensure that these machines function correctly and maintain high efficacy.

The aerospace industry, with its stringent safety and reliability requirements, also benefits from the use of specialized oil seals like the 25% 2035 7. In this context, oil seals need to withstand extreme conditions, such as rapid pressure changes and high-speed rotation. The precise engineering of this particular seal provides the assurance needed for critical flight systems.

Factors to Consider When Choosing Oil Seals

When selecting oil seals such as the 25% 2035 7, several factors should be considered. First, the operating environment plays a significant role. Temperature fluctuations, exposure to chemicals, and pressure levels must be analyzed to ensure that the chosen seal will last.

Second, compatibility with the lubricants used is crucial. Different materials may react differently to various oils, which can affect the integrity and longevity of the seal. Engineers must also consider the load and movement type—static or dynamic—that the seal will experience.

Finally, understanding the installation process is essential. An improperly installed oil seal, regardless of its quality, can lead to premature failure and leakage. Proper training and guidance should be provided to those tasked with installing these components.

Conclusion

The 25% 2035 7 oil seal is a vital component in numerous industrial applications, offering exceptional performance and reliability. By understanding its specifications and the importance of oil seals in machinery, engineers and manufacturers can make informed decisions that enhance the efficiency and longevity of their equipment. As technology continues to advance, the demand for high-quality oil seals will only increase, making it essential to keep abreast of developments in this critical area of engineering.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories