Nov . 15, 2024 23:25 Back to list

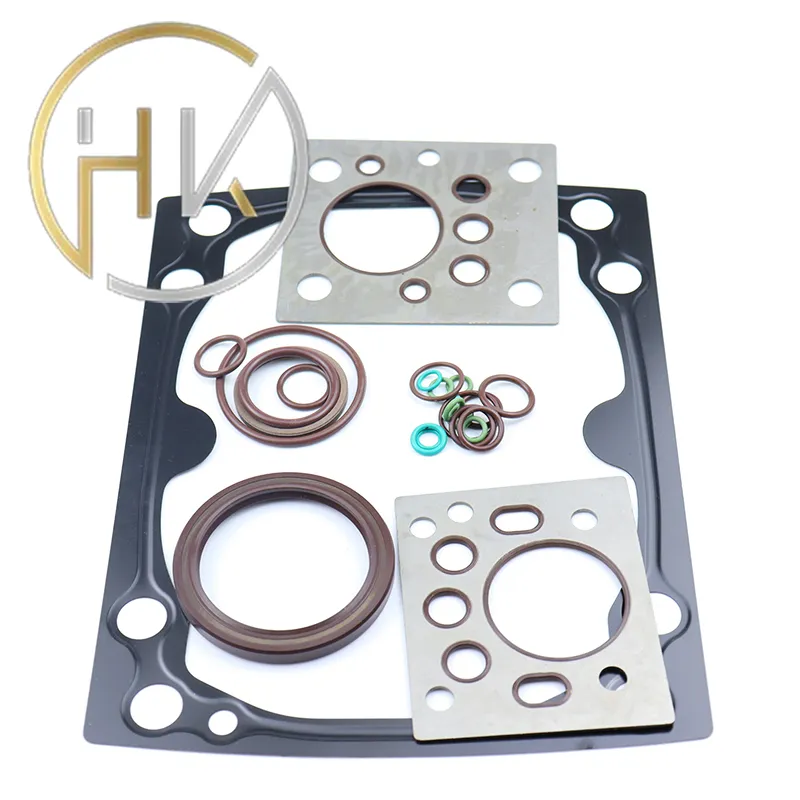

22 40 7 oil seal

The Significance of 22% 40% 7% Oil Seal in Modern Industry

In the realm of industrial applications, the importance of oil seals cannot be overstated. Essential for preventing leakage and protecting machinery from contaminants, oil seals are integral components in various operations. Among the numerous specifications available, the 22% 40% 7% oil seal emerges as a noteworthy example, embodying specific characteristics and serving unique functions that illustrate the broader role of sealing solutions in industry.

The Significance of 22% 40% 7% Oil Seal in Modern Industry

One primary advantage of the 22% 40% 7% oil seal is its exceptional resistance to wear and tear. The formulation provides durability, reducing the need for frequent replacements that can lead to prolonged downtime and increased operational costs. This aspect is crucial in sectors where machinery operates under high-stress conditions, emphasizing the necessity of reliable sealing solutions. Additionally, the design of the oil seal allows it to create a robust barrier against the intrusion of dirt, dust, and other contaminants, which can significantly impact equipment performance and longevity.

22 40 7 oil seal

Moreover, the specific attributes of the 22% 40% 7% oil seal play a vital role in ensuring energy efficiency. By minimizing friction and gas leakage within mechanical systems, these seals help maintain optimal performance while reducing energy consumption. This is particularly relevant as industries increasingly prioritize sustainability and seek to lower their environmental impact. Implementing high-quality sealing solutions contributes to these goals, promoting a greener approach to manufacturing and production.

Furthermore, the versatility of the 22% 40% 7% oil seal is illustrated by its applicability across various sectors. Whether in automotive applications where engine components require sealing from the oil supply, or in hydraulic systems where fluid retention is critical, the performance of this oil seal is consistent and reliable. This flexibility makes it an essential asset for engineers and designers seeking to achieve optimal results in their projects.

In conclusion, the 22% 40% 7% oil seal exemplifies the critical importance of sealing technologies in modern industry. Its unique composition fosters durability, efficiency, and versatility, addressing the diverse needs of numerous applications. As industries continue to evolve, the demand for effective sealing solutions like the 22% 40% 7% oil seal will only increase. By ensuring machinery operates smoothly and efficiently, these seals play a crucial role in enhancing productivity and achieving operational goals. As we look to the future, the ongoing advancements in material science and engineering will undoubtedly lead to even more innovative sealing solutions, further solidifying the significance of components like the 22% 40% 7% oil seal in industrial processes.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories