Nov . 01, 2024 19:50 Back to list

20x35x7 Oil Seal Specifications and Applications for Various Mechanical Uses

Understanding the 20x35x7 Oil Seal A Key Component in Machinery

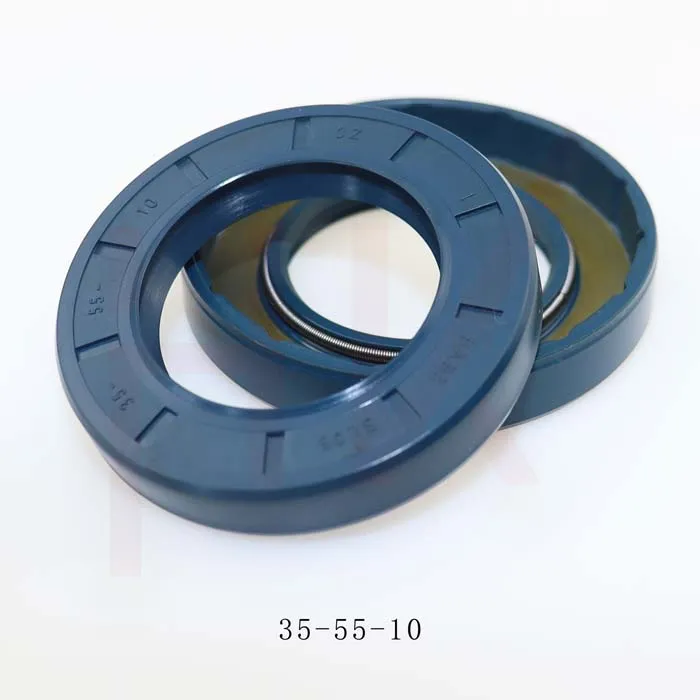

Oil seals, also known as oil seals or rotary shaft seals, are essential components used in various mechanical systems to prevent the leakage of lubricants while keeping out contaminants. One of the commonly used dimensions in this category is the 20x35x7 oil seal. This specific size indicates the seal's inner diameter (20 mm), outer diameter (35 mm), and width (7 mm), making it suitable for a range of applications across different industries.

The Importance of Oil Seals in Mechanical Systems

Oil seals play a critical role in ensuring the efficiency and longevity of machinery. They create a robust barrier between the internal components, which require lubrication, and the external environment. Without effective seals, oil leakage can lead to operational failures, increased wear and tear, and significant maintenance costs.

The 20x35x7 oil seal is designed to withstand various conditions, including pressure and temperature fluctuations. The seal's construction materials, often elastomeric compounds or synthetic rubbers, possess excellent resistance to oil, heat, and wear, ensuring they retain their integrity over time.

Applications of 20x35x7 Oil Seals

This specific oil seal size is prevalent in a wide array of applications. Commonly, it can be found in automotive industries, particularly in engines, transmissions, and differentials. It ensures that lubricants remain within the gearbox or engine block, preventing contamination by dust or dirt. In industrial machinery, the 20x35x7 oil seal is crucial for ensuring hydraulic systems are sealed efficiently, safeguarding against fluid leaks.

20x35x7 oil seal

Moreover, these seals are also utilized in household appliances, such as washing machines and refrigerators, where they help maintain the system's lubrication and prevent water ingress.

Choosing the Right Oil Seal

When selecting the appropriate oil seal for a specific application, several factors should be considered. The first is the compatibility of the material with the type of lubricant being used. For instance, certain oils may degrade specific materials faster, leading to premature seal failure.

Additionally, the operating temperatures and pressures must be accounted for. The 20x35x7 oil seal is often rated to perform within a specified range; exceeding these limits can compromise seal integrity.

Furthermore, the shaft and housing tolerances should match the seal dimensions, ensuring a snug fit that prevents leaks. Proper installation is equally vital; even the best seal can fail if not installed correctly.

Conclusion

In conclusion, the 20x35x7 oil seal is a vital component in various mechanical systems, ensuring that lubricants remain contained while protecting against contaminants. Its widespread use in automotive and industrial applications highlights its importance in maintaining machinery efficiency. By understanding the characteristics and applications of this oil seal, users can make informed decisions when selecting and maintaining seals, leading to increased reliability and longevity of their machinery. As technology evolves, the materials and designs of oil seals continue to improve, promising even greater performance in the future.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories