Jan . 13, 2025 12:10 Back to list

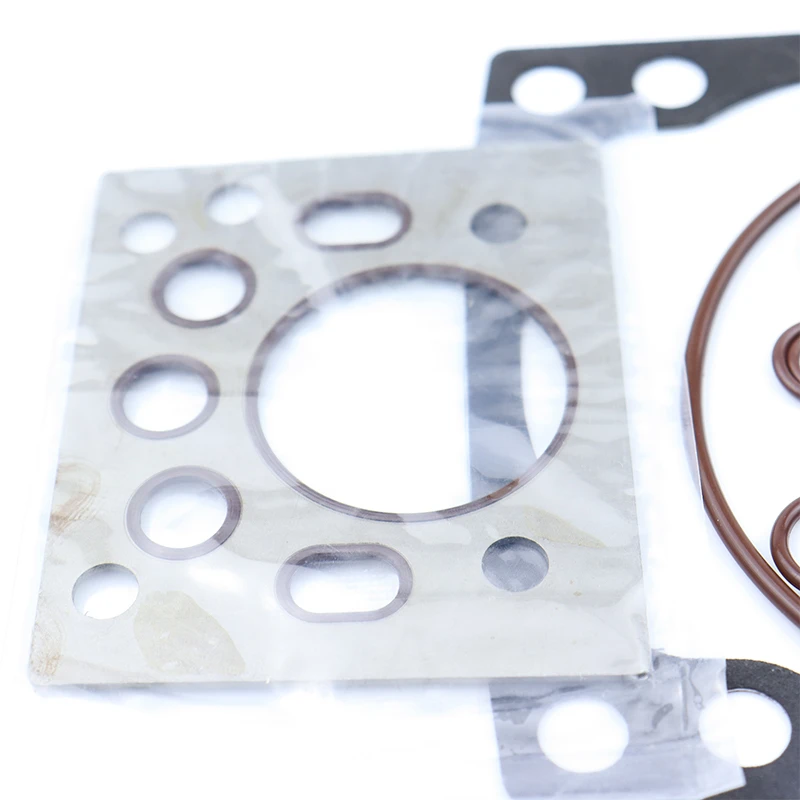

20x30x7 oil seal

The credibility of the supplier from whom the oil seal is purchased is another critical factor in selecting the 20x30x7 oil seal. Reputable manufacturers ensure that their seals meet high-quality standards and are often subjected to rigorous testing processes. This guarantees that their products are not only durable but also reliable in various operational conditions, thereby providing peace of mind for business operators. Furthermore, understanding the specific requirements of your application is essential for making informed decisions. Consulting with experts or engineers can offer valuable insights into the best type of oil seal for your particular needs, ensuring that all operational parameters are met. In conclusion, the 20x30x7 oil seal is a crucial component that requires careful consideration in terms of its material, supplier credibility, and application suitability. By focusing on these aspects, industry professionals can enhance machinery efficiency, minimize operational downtime, and safeguard against potential operational failures. Recognizing and integrating these factors will ultimately translate into sustained productivity and cost-effectiveness within industrial processes.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories