Nov . 24, 2024 23:02 Back to list

Dimensions and Performance of 20x30x7 Oil Seal for Various Applications

Understanding the 20x30x7 Oil Seal An Essential Component for Machinery Reliability

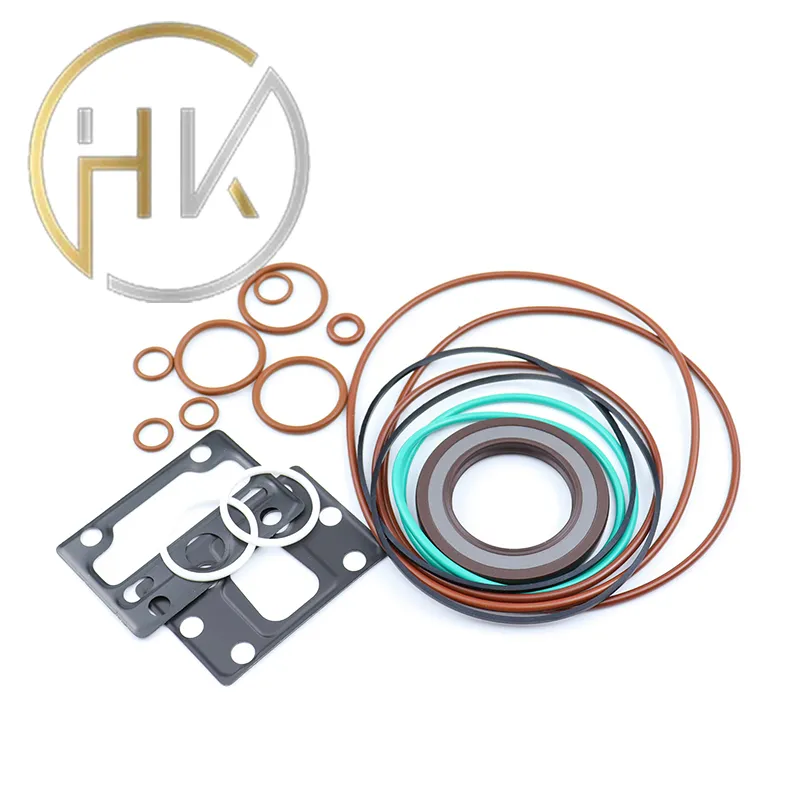

In the world of machinery and mechanical systems, the efficiency and longevity of equipment often hinge on the reliability of the components used within them. One such critical component is the oil seal, specifically the 20x30x7 oil seal. This particular size refers to the seal's dimensions a 20 mm inner diameter, a 30 mm outer diameter, and a thickness of 7 mm. Understanding the role and characteristics of this oil seal can help maintenance personnel and engineers ensure optimal performance in various applications.

The primary function of an oil seal is to prevent the leakage of lubricating oil while simultaneously protecting against the ingress of dirt and moisture. In many machinery configurations, ensuring that lubricant stays within the system is vital for minimizing friction and wear on moving parts. The 20x30x7 oil seal is specifically designed to fit into areas where these requirements are crucial, such as in automotive applications, gearboxes, and other machinery where reliability is paramount.

The 20x30x7 oil seal is generally made from durable materials such as rubber or thermoplastic elastomers. These materials offer excellent resistance to oil, heat, and wear, which is essential for maintaining the seal’s integrity over time. Additionally, the design often incorporates spring elements that help maintain the seal's contact with the shaft, ensuring a tight fit that mitigates leaks even in high-pressure environments.

20x30x7 oil seal

Installation of the oil seal is a critical process. Proper installation ensures that the seal will function optimally for its expected lifespan, which can range from several thousand to tens of thousands of operating hours, depending on the application and operating conditions. A misaligned or improperly seated oil seal can lead to premature failure and costly downtime for repairs or replacements. Therefore, attention to detail during installation is key.

In terms of applications, the versatility of the 20x30x7 oil seal cannot be overstated. This seal is commonly used in various industries, including automotive, manufacturing, and even aerospace. Its ability to effectively contain lubricants while providing a barrier against contaminants makes it ideal for use in engines, differential assemblies, and hydraulic systems. The demand for such seals underscores their vital role in the efficient operation of mechanical systems.

In summary, the 20x30x7 oil seal is a small yet significant component in the broad landscape of machinery and mechanical engineering. By preventing oil leaks and protecting internal components from contaminants, it plays a crucial role in maintaining equipment efficiency and reliability. As industries continue to evolve and technology advances, the development and application of oil seals will remain integral to ensuring that machinery operates seamlessly. Understanding the importance of such components is essential for anyone involved in the maintenance or design of mechanical systems, promoting longevity and performance in various applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories