Nov . 10, 2024 07:15 Back to list

Alternative Specifications for 20% 2035 7 Oil Seal Variants

Understanding the 20 35 7 Oil Seal Key Features and Applications

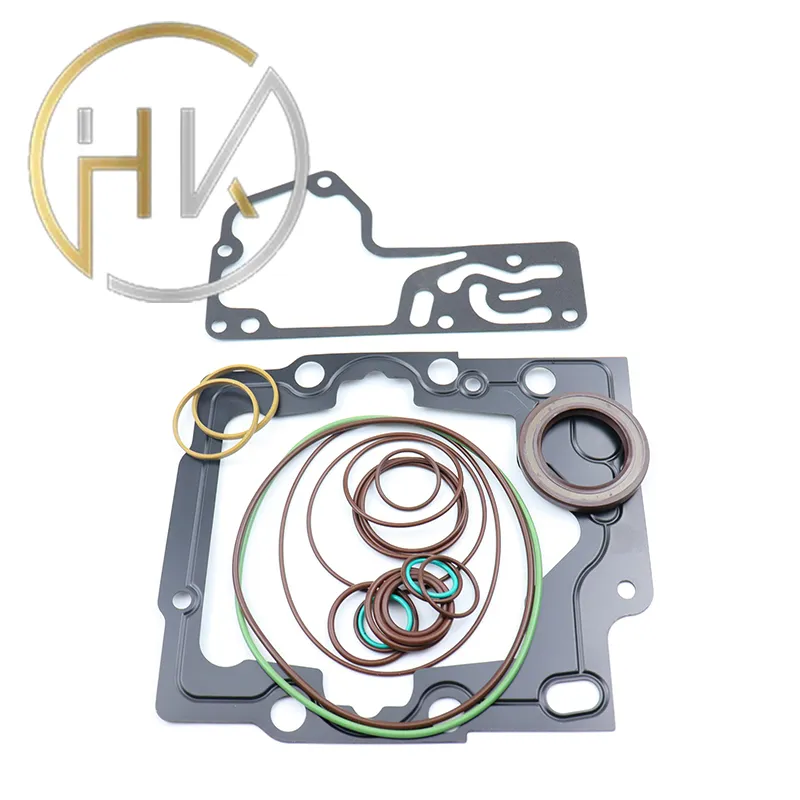

Oil seals play a pivotal role in various industrial and automotive applications, ensuring the effective sealing of lubricants and fluids within mechanical systems. Among the numerous oil seals available in the market, the 20 35 7 oil seal stands out for its unique specifications and versatile applications. In this article, we will delve into the characteristics, applications, and benefits of using a 20 35 7 oil seal.

What is an Oil Seal?

An oil seal, also known as a shaft seal, is a mechanical component that ensures that lubricating oil or grease does not leak from a component while also preventing dust and contaminants from entering. These seals are integral in numerous applications, from automotive engines to industrial machinery, where the integrity of lubricating fluids is crucial for optimal performance.

Key Specifications of the 20 35 7 Oil Seal

The designation 20 35 7 may seem cryptic at first glance, but it provides critical information regarding the seal's dimensions and capabilities. Typically, this notation indicates the following

- Internal Diameter (ID) The first number, 20, likely refers to the inner diameter of the seal in millimeters. This is the size of the shaft that the seal will fit around. - External Diameter (ED) The second number, 35, denotes the outer diameter of the seal. This measurement is crucial for ensuring that the seal fits correctly within the housing or bore.

- Width or Thickness The last number, 7, indicates the thickness of the seal. The width of the seal plays a significant role in its ability to withstand pressure and maintain an effective seal.

These specifications point to a seal that is relatively small, making it suitable for various applications where space constraints are a factor.

Material Considerations

Oil seals are made from a variety of materials, each chosen for its specific properties and suitability for various environments. Common materials include

- Nitrile Rubber (NBR) Known for its excellent resistance to oil and heat, NBR is a popular choice for oil seals, especially in automotive applications.

- Fluoroelastomer (FKM) Offering superior temperature resistance and chemical compatibility, FKM is ideal for high-performance applications, particularly in environments with exposure to aggressive fluids.

- Polyurethane This material combines flexibility with wear resistance, making it suitable for dynamic sealing applications.

Choosing the right material for the 20 35 7 oil seal ensures optimal performance in terms of longevity and resistance to the operating conditions it will face

.20 35 7 oil seal

Applications of the 20 35 7 Oil Seal

The versatility of the 20 35 7 oil seal makes it suitable for a wide range of applications, including but not limited to

1. Automotive Industry These seals are used in engines, transmissions, and differential assemblies to prevent oil leaks and protect critical components from contamination.

2. Industrial Machinery In factories and production facilities, oil seals are essential for maintaining the integrity of hydraulic systems, pumps, and motors.

3. Agricultural Equipment Farming machinery often operates under challenging conditions, making reliable oil seals crucial for longevity and performance.

4. Aerospace Applications Oil seals in aircraft and space vehicles must meet stringent safety and performance standards, where a failure could lead to catastrophic results.

Advantages of the 20 35 7 Oil Seal

Using a properly specified oil seal like the 20 35 7 offers several advantages

- Leak Prevention Ensures that lubricants remain contained within the system, minimizing waste and operational disruptions.

- Contamination Protection Prevents dirt, dust, and moisture from entering sensitive components, which is especially vital for longevity.

- Easy Installation The standardized size of the seal simplifies the replacement process, reducing downtime in maintenance operations.

- Cost-Effectiveness Investing in high-quality oil seals can ultimately lead to savings by reducing the frequency of repairs and replacements due to seal failure.

Conclusion

The 20 35 7 oil seal is a crucial component in ensuring the smooth operation of various machines and vehicles. Understanding its specifications helps in selecting the right seal for specific applications, emphasizing the need for material compatibility and proper installation. By leveraging the advantages of this oil seal, industries can enhance their operational efficiency and prolong equipment life, proving that even the smallest components can have a significant impact on performance.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories