Dec . 25, 2024 03:59 Back to list

Oil Seal Specifications for Enhanced Performance in 20% 2032 6 Applications

Understanding the 20% 2032 6 Oil Seal Importance, Applications, and Maintenance

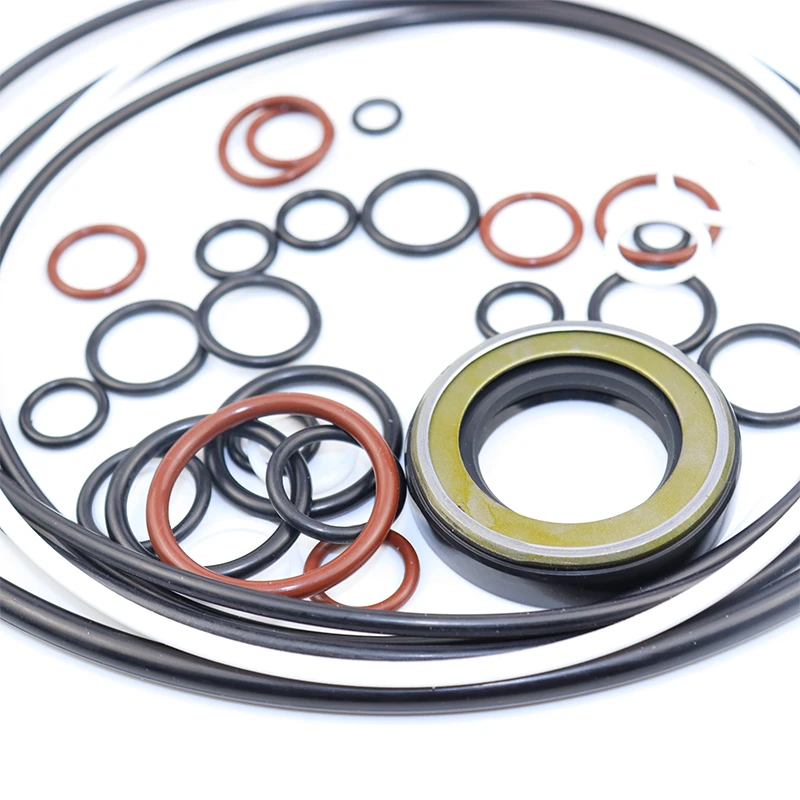

The oil seal is a crucial component in various mechanical systems, primarily serving to prevent lubricant leakage and contamination from external elements. Among the wide range of oil seals available in the market, the 20% 2032 6 oil seal stands out for its unique specifications and versatility. In this article, we will delve into what this particular oil seal is, its applications, and how to ensure its proper maintenance.

What Is the 20% 2032 6 Oil Seal?

The designation 20% 2032 6 typically refers to specific dimensions and material properties of the oil seal. The number 2032 suggests the seal's inner and outer diameter, often noted in millimeters. The 20% could imply a specific percentage composition of the material used in the seal, which plays a crucial role in determining its compatibility with various oils and operating conditions. Finally, the “6” may denote the seal's thickness, contributing to its durability and effectiveness.

Oil seals are generally composed of elastomeric materials like nitrile rubber (NBR), fluorocarbon rubber (FKM), or silicone. The choice of material affects temperature resistance, chemical compatibility, and wear characteristics. The 20% 2032 6 oil seal is designed to provide reliable performance across various environments, making it suitable for both low and high-pressure applications.

Applications of the 20% 2032 6 Oil Seal

Due to its robust design, the 20% 2032 6 oil seal finds application in numerous industries

.1. Automotive Sector In vehicles, these seals are often used in engines, transmissions, and differential systems to ensure that lubricants remain contained while blocking dirt and moisture from entering sensitive components.

2. Industrial Machinery Equipment such as pumps, compressors, and hydraulic systems rely on oil seals to maintain operational integrity. The 20% 2032 6 oil seal helps protect machine parts from wear and tear caused by lubricant leakage.

3. Agricultural Equipment Tractors and other machinery used in agriculture often operate in harsh conditions. The reliability of oil seals in such equipment is paramount to ensure minimal downtime and maximum productivity.

20 32 6 oil seal

4. Household Appliances Many home appliances, such as refrigerators and washing machines, utilize oil seals for motors and pumps. The effectiveness of these seals can directly influence energy efficiency and appliance longevity.

Importance of Proper Maintenance

To maximize the lifespan and functionality of the 20% 2032 6 oil seal, regular maintenance is essential. Here are some best practices

- Regular Inspections Conduct routine checks to identify any signs of wear, such as cracks or deformation. Early detection can prevent costly repairs and replacements.

- Proper Installation Ensure that the oil seal is installed correctly, adhering to the manufacturer's specifications. Improper installation can lead to premature failure.

- Lubrication While the oil seal is designed to keep lubricants in and contaminants out, ensuring proper lubrication in the system it supports is vital for overall functionality. Inadequate lubrication can increase friction and lead to overheating.

- Environment Considerations Be mindful of the operating conditions, such as temperature and chemical exposure. Operating outside of recommended specifications can compromise the seal's effectiveness.

- Replacement Schedule Based on operational demands and wear patterns, establish a replacement schedule for the oil seals. Regular replacements will help maintain optimal performance and prevent unexpected failures.

Conclusion

The 20% 2032 6 oil seal is a testament to the engineering advancements tailored for specific applications across multiple industries. Understanding its functions, applications, and maintenance requirements can greatly enhance system reliability and efficiency. As with any mechanical component, vigilance and proactive care are key to ensuring that these seals perform at their best, safeguarding the integrity of the systems in which they are employed. By investing time in understanding and maintaining oil seals, individuals and businesses can harness their full potential and mitigate the risks associated with lubricant loss and contamination.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories