Sep . 14, 2024 16:40 Back to list

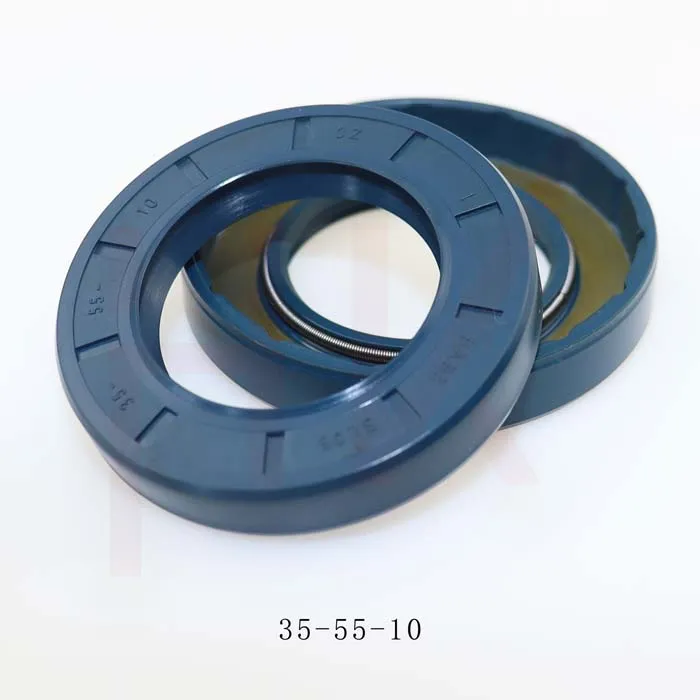

20 32 6 oil seal

Understanding the 20% 2032 6 Oil Seal A Key Component in Machinery

In the vast world of machinery and equipment, the components that ensure smooth operations often go unnoticed. Among these critical parts is the oil seal, specifically the 20% 2032 6 oil seal. This seal plays an essential role in maintaining the integrity of various mechanical systems, preventing leaks, and ensuring optimal performance.

An oil seal is designed to retain lubrication within a system while preventing external contaminants from entering. The nomenclature 20% 2032 6 likely indicates specific dimensions or specifications of the seal, such as its size, shape, and material properties. Understanding these details can help engineers and technicians select the right seal for their applications.

Importance of the Oil Seal

Oil seals are crucial in various applications, from automotive engines to industrial machinery. They prevent oil leaks, which can lead to reduced efficiency and potential damage. In engines, for instance, the oil seal creates a pressing barrier against the high-pressure environment, ensuring that the oil remains contained within the system. Not only does this promote lubrication, but it also protects components from wear and tear caused by dirt and other foreign particles.

Material and Design

20 32 6 oil seal

The 20% 2032 6 oil seal is often made from elastomeric materials that provide flexibility and resilience under pressure. Common materials include nitrile rubber (NBR), fluorocarbon (FKM), and silicone. Each material has unique properties, making them suitable for different operating environments. For instance, NBR is known for its excellent resistance to petroleum-based oils, while FKM performs well in high-temperature applications.

In terms of design, the shape and configuration of the oil seal are engineered to fit specific shaft sizes and diameters. Proper fitting is crucial, as an improper seal can lead to leaks, resulting in costly downtime and repairs. Therefore, understanding the application and selecting the correct oil seal is paramount for effective machinery operation.

Maintenance and Longevity

Like all mechanical components, oil seals require regular maintenance checks to ensure their functionality. Factors such as temperature fluctuations, exposure to chemicals, and operational pressure can impact their lifespan. Regular inspection can help identify wear and tear, allowing for proactive replacements before a seal fails.

In summary, the 20% 2032 6 oil seal is a vital component in many machinery systems. Its role in preventing leaks and maintaining lubrication cannot be overstated. Selection based on accurate specifications and regular maintenance can significantly enhance the performance and lifespan of the machinery it protects. Understanding and respecting these components lead to more efficient operations and reduced maintenance costs, ultimately contributing to a more productive working environment.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories