Jan . 13, 2025 11:26 Back to list

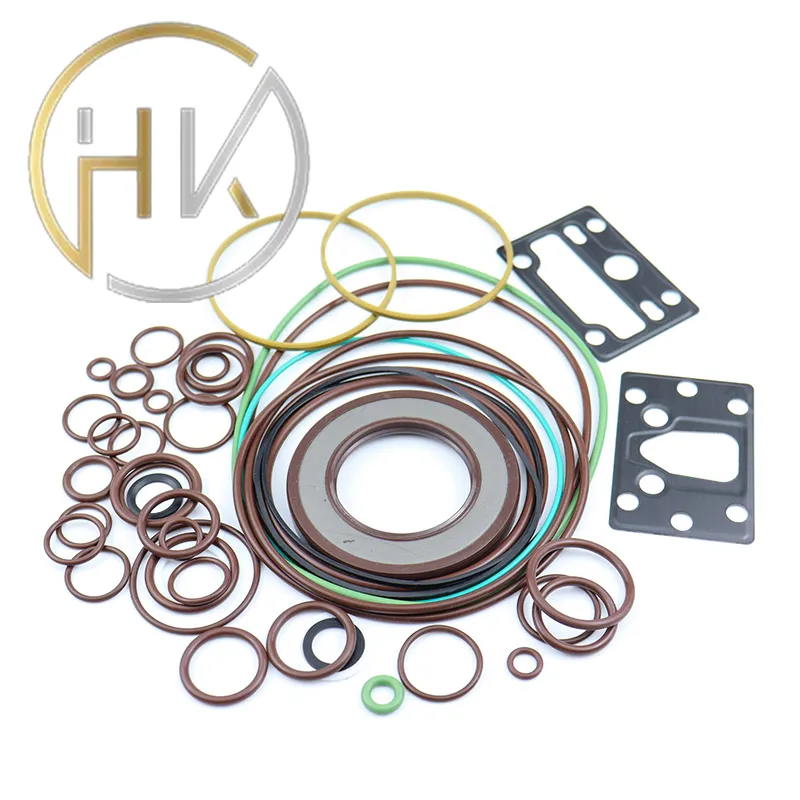

17x40x7 seal

One major consideration for utilizing the 17x40x7 seal is the environment in which it operates. The seal’s effectiveness is influenced by the pressures and temperatures of the application. Selecting the right seal involves a comprehensive understanding of these parameters. Industry experts underscore rigorous testing and verification processes to ensure reliability, especially when these components are used in critical systems. The trustworthiness of the 17x40x7 seal is not merely dependent on its manufacturing process but also on the brand’s commitment to quality and engineering excellence. Reviews and real-world testing have consistently shown that when this seal is applied correctly, it maintains its integrity over prolonged periods, even in harsh operating conditions. Thus, making an educated choice based on manufacturer reputation and material quality is indispensable. In industries where downtime equates to financial setbacks, reliance on well-engineered components like the 17x40x7 seal is non-negotiable. The seal is a quintessential example of how a small part can play a significant role in ensuring overall system efficiency, safety, and cost-effectiveness. For any business or engineer aiming to enhance machinery efficiency, understanding the intricacies and applications of seals such as the 17x40x7 is a critical step. It's a component whose value and necessity are underscored by its capacity to provide seamless operations across a myriad of demanding industrial landscapes.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories