Nov . 16, 2024 09:26 Back to list

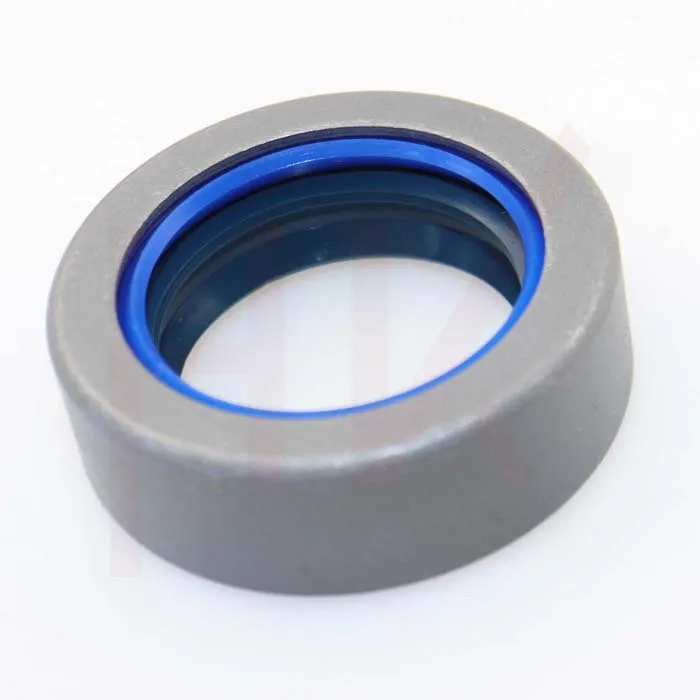

17x30x7 oil seal

Understanding the Oil Seal The 17x30x7 mm Dimension

An oil seal, a vital component in mechanical applications, serves a crucial function in preventing the leakage of lubricants and the ingress of contaminants. The specifications of oil seals, such as the dimension 17x30x7 mm, provide important information regarding their design and application. This article delves into the significance of these dimensions, the working principle of oil seals, their materials, and their applications in various industries.

Dimensions Explained

The dimensions 17x30x7 mm represent the inner diameter, outer diameter, and thickness of the oil seal, respectively. The inner diameter (ID) of 17 mm is the size of the shaft or opening that the oil seal fits onto, while the outer diameter (OD) of 30 mm indicates how far the seal extends outward. The thickness of 7 mm refers to the height of the seal. Such specific dimensions are critical in ensuring a proper fit in machinery, thus preventing oil leakage and maintaining efficient operation.

Working Principle

Oil seals work on a simple principle they create a barrier that prevents fluids from leaking out and contaminants from entering. When installed correctly, an oil seal conforms tightly to the shaft, creating a dynamic seal. This means that as the shaft rotates, the oil seal rotates with it, ensuring that it maintains contact and effectively blocks unwanted substances. The sealing lip, which is a crucial feature of the oil seal, often has a spring that applies pressure against the shaft, enhancing the seal's effectiveness.

In automotive and industrial applications, the oil seal is critical for maintaining lubrication within systems like engines, gearboxes, and hydraulic systems. Without a properly functioning oil seal, the lubricating oil could leak out, leading to increased friction and wear on internal components, ultimately resulting in mechanical failure.

Materials Used in Oil Seals

The materials used to manufacture oil seals significantly influence their performance and longevity. Common materials include rubber, silicone, and various thermoplastics.

- Nitrile Rubber (NBR) This is one of the most popular materials for oil seals due to its excellent resistance to petroleum oils and fuels. It performs well in a range of temperatures and has good wear resistance. - Fluoroelastomer (FKM) Known for its superior resistance to heat and aggressive chemicals, FKM is often used in high-performance applications where extreme conditions are present.

17x30x7 oil seal

- Polyurethane This material is known for its high elasticity and tensile strength, making it suitable for dynamic applications.

The choice of material depends on the specific requirements of the application, including the type of fluid being sealed, the operational temperature range, and the pressure conditions.

Applications in Various Industries

The versatility of oil seals allows them to be used across various industries.

1. Automotive In vehicles, oil seals are widely used in engines, transmissions, and differentials. They prevent the loss of engine oil and ensure that debris does not enter the lubrication systems.

2. Industrial Machinery Oil seals are essential in hydraulic systems to ensure efficient operation by keeping hydraulic fluids contained while preventing contaminants from entering.

3. Aerospace In aerospace applications, oil seals must meet strict safety and performance standards, given the critical nature of components like engines and gearboxes.

4. Appliances Everyday appliances, such as washing machines and vacuum cleaners, utilize oil seals to prevent leaks, ensuring efficient operation.

Conclusion

In summary, the 17x30x7 mm oil seal is a small yet pivotal component in countless mechanical systems. Understanding its dimensions, working principles, materials, and applications is essential for anyone involved in engineering or maintenance. Proper selection and installation of oil seals not only ensure the longevity and reliability of equipment but also contribute to improved efficiency and reduced operational costs. The significance of components like the oil seal cannot be understated, as they play a crucial role in the smooth functioning of machinery in our daily lives.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories