Nov . 08, 2024 21:14 Back to list

17x30x7 oil seal

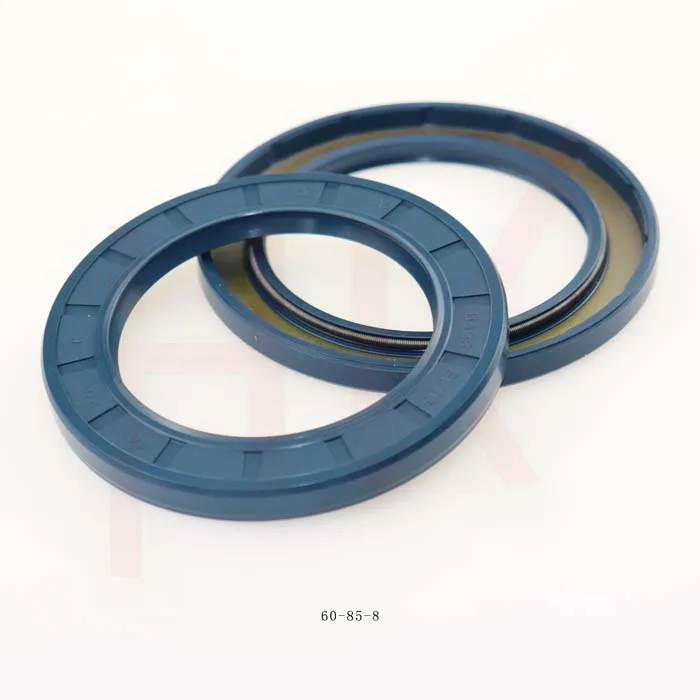

Understanding the 17x30x7 Oil Seal A Comprehensive Guide

In the realm of mechanical engineering and automotive design, oil seals play a critical role in ensuring the efficiency and longevity of machinery. One particular oil seal that stands out in terms of application and performance is the 17x30x7 oil seal. This article delves into the specifications, applications, benefits, and installation tips for the 17x30x7 oil seal.

Specifications

The designation 17x30x7 refers to the dimensions of the oil seal, where each number indicates the measurements in millimeters. The first number, 17 mm, represents the inner diameter of the seal; the second number, 30 mm, indicates the outer diameter; and the third number, 7 mm, describes the thickness of the seal. These precise dimensions make the 17x30x7 oil seal suitable for various applications, particularly in machinery where space constraints and specific tolerances are common.

Oil seals are typically made from a variety of materials, including rubber and synthetic compounds. The choice of material is crucial because it directly impacts the seal's resistance to temperature fluctuations, chemical exposure, and wear over time. The 17x30x7 oil seal often features elastomeric materials that provide flexibility and durability, ensuring a reliable barrier against leakage.

Applications

The versatility of the 17x30x7 oil seal allows it to be used in an array of applications across different industries. It is commonly found in automotive equipment, such as engines, gearboxes, and wheel hubs, where it helps prevent oil leakage and protects critical components from contamination. Additionally, this size of oil seal is utilized in industrial machines, hydraulic systems, and agricultural equipment.

In automotive applications, the seal functions to maintain lubrication in critical moving parts, enhancing performance and minimizing wear. In hydraulic systems, the oil seal is vital for maintaining pressure and ensuring the efficient operation of hydraulic cylinders. Its applications are vast, making it an essential component in ensuring the reliability of numerous machines and vehicles.

Benefits

Using the 17x30x7 oil seal offers several significant benefits. Firstly, it helps prevent oil leaks, which can lead to decreased efficiency, increased maintenance costs, and potential damage to machinery. By providing a reliable seal, it plays a crucial role in maintaining the proper lubrication of moving parts, thus extending the life of the equipment.

Secondly, these seals are designed to withstand various operating conditions, including extreme temperatures and exposure to harsh chemicals. Their robust construction ensures that they maintain performance over time, minimizing the risk of failure and the need for frequent replacements.

17x30x7 oil seal

Lastly, the 17x30x7 oil seal contributes to the overall cleanliness of machinery by preventing contaminants such as dust and water from entering critical areas. This protection is vital in ensuring optimal performance and longevity.

Installation Tips

Proper installation of the 17x30x7 oil seal is essential for its effectiveness. Here are some key tips for ensuring a successful installation

1. Preparation Clean the sealing surfaces to remove any debris or old sealant. This ensures a proper fit and aids in achieving an effective seal.

2. Alignment Ensure the oil seal is aligned correctly with the housing and shaft. Misalignment can lead to premature wear and failure.

3. Lubrication Apply a thin layer of lubricant on the contact surfaces of the seal to facilitate easy installation and prevent damage during the process.

4. Use the Right Tools Utilize appropriate tools to press the seal into place, avoiding excessive force that could deform the seal.

5. Check for Proper Fit After installation, ensure that the seal is flush with the housing and securely fitted.

Conclusion

The 17x30x7 oil seal is a vital component in many mechanical systems, enhancing performance and reliability. Understanding its specifications, applications, benefits, and installation procedures can help ensure the optimal functioning of machinery and vehicles. Whether you're a mechanical engineer, an automotive technician, or a DIY enthusiast, the knowledge of oil seals, particularly the 17x30x7 variant, is invaluable in maintaining the integrity of your equipment.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories