Dec . 06, 2024 10:51 Back to list

14x28x7 oil seal

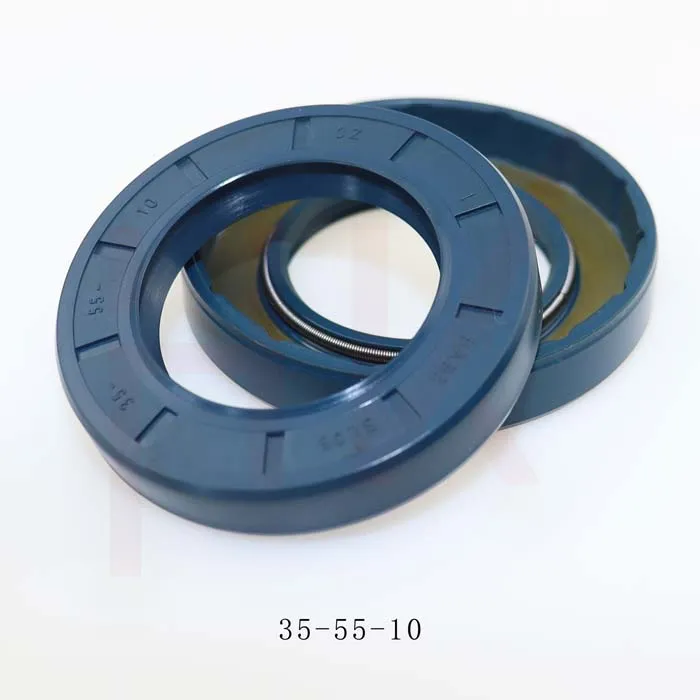

Understanding the 14x28x7 Oil Seal Key Features and Applications

In the world of machinery and equipment, oil seals play a crucial role in ensuring efficiency and longevity. One such common type is the 14x28x7 oil seal. These seals are designed to prevent the leakage of lubricants and fluids while protecting internal components from contamination by dust, dirt, and other external elements. Understanding the specifications, features, materials, and applications of this specific oil seal can help in selecting the right product for various engineering and mechanical needs.

Specifications and Dimensions

The designation 14x28x7 refers to the dimensions of the oil seal. Specifically, it indicates a nominal inner diameter of 14 mm, an outer diameter of 28 mm, and a lip width of 7 mm. These measurements are essential as they determine the seal's fit within a given mechanism. Proper sizing is critical; an incorrect fit can lead to inefficiencies, such as leaks that can jeopardize the performance and reliability of machinery.

Materials Used

Oil seals are typically made from a range of materials, each offering unique properties suitable for different applications. Common materials include rubber compounds like Nitrile (Buna-N), Fluoroelastomer (FKM), and Polyurethane.

1. Nitrile Rubber This is the most common material for oil seals due to its excellent resistance to petroleum-based oils, grease, and water, along with good mechanical properties. It operates effectively in temperatures ranging from -40°C to +100°C.

2. Fluoroelastomer (FKM) For applications involving high temperatures or aggressive chemicals, FKM provides superior heat and chemical resistance. It can withstand temperatures up to 200°C and is often used in aerospace and automotive industries.

3. Polyurethane Known for its outstanding abrasion resistance and flexibility, polyurethane can also handle temperature extremes. It's ideal for heavy-duty applications where durability is paramount.

Functions and Importance

The primary purpose of an oil seal, including the 14x28x7 variant, is to retain lubricants within a mechanical assembly and prevent external contaminants from entering. This retention is vital for several reasons

14x28x7 oil seal

1. Lubrication Proper lubrication reduces friction between moving parts, which in turn minimizes wear and tear. An oil seal ensures that the lubricant stays where it's supposed to be, prolonging the life of components.

2. Contamination Prevention Oil seals prevent dust, dirt, and moisture from infiltrating the internal mechanisms. This is especially important in harsh operating environments, where contaminants can cause severe damage and lead to costly downtime.

3. Reduction of Emissions In some applications, such as in automotive engines, effective seals help reduce environmental pollution by containing lubricants and preventing leaks.

Applications

The versatility of the 14x28x7 oil seal allows it to be used in various industries and applications

1. Automotive Commonly found in engines, transmissions, and differentials, these seals help maintain optimal performance and efficiency levels by ensuring that lubricants remain where they are needed most.

2. Industrial Machinery Equipment such as pumps, compressors, and gearboxes rely on oil seals to protect bearings and other critical components from excessive wear and degradation.

3. Agricultural Equipment Tractors and farming machinery often utilize oil seals to ensure operational integrity in challenging outdoor environments.

4. Construction Machinery Heavy-duty machinery involved in construction and earthmoving frequently uses oil seals to protect hydraulic systems and rotating equipment.

Conclusion

The 14x28x7 oil seal is a small yet significant component in many mechanical systems. Understanding its features, materials, and applications is essential for engineers and technicians looking to maintain or enhance equipment performance. When selecting an oil seal, one must consider various factors, including compatibility with fluids, temperature conditions, and the specific application environment. By ensuring that the right oil seal is utilized, one can significantly extend the lifespan of equipment and improve overall operational efficiency.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories