Dec . 01, 2024 23:19 Back to list

14x22x5 oil seal

Understanding the Importance of 14x22x5 Oil Seals in Mechanical Applications

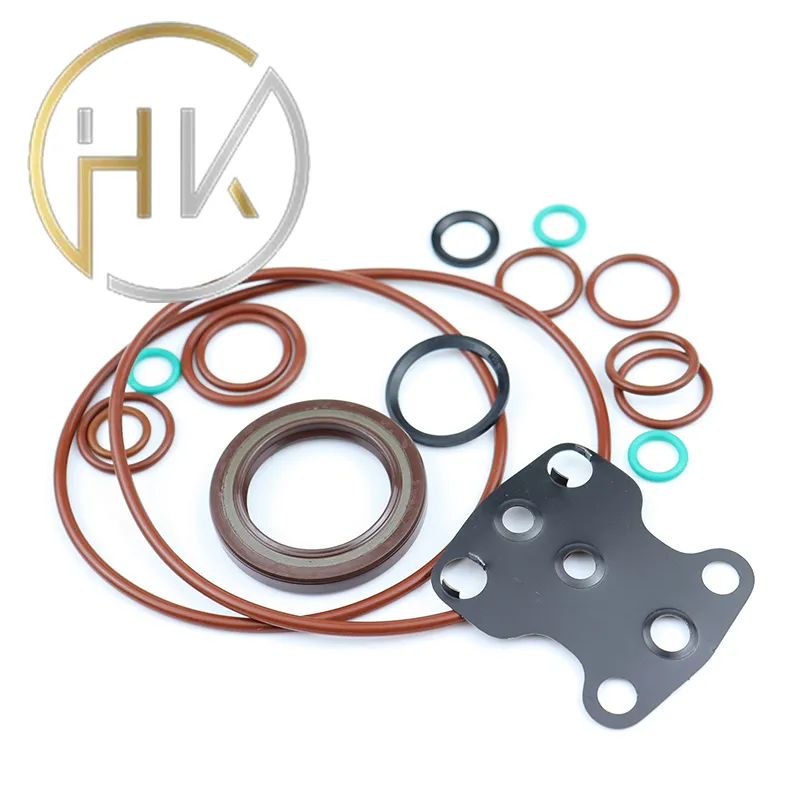

Oil seals, also known as lip seals or hydraulic seals, are critical components in various mechanical systems. They are designed to prevent the leakage of lubricants and protect against the ingress of dirt, water, and other contaminants. Among the myriad types of oil seals available in the market, the 14x22x5 oil seal holds a significant position due to its specific dimensions and versatile applications.

Specifications and Design

The designation of 14x22x5 refers to the oil seal's inner diameter (14 mm), outer diameter (22 mm), and width (5 mm). These measurements are crucial as they determine the fit and compatibility of the oil seal with shafts and housings. The design of the oil seal typically includes a rubber body and a metal casing. The rubber lip creates a dynamic seal that conforms to the shaft's surface, ensuring minimal leakage and excellent sealing performance.

The materials used in manufacturing these seals are equally important. The rubber compounds are often resistant to oil, temperature fluctuations, and environmental factors, enhancing the seal's durability and longevity. Depending on the specific application requirements, variations in hardness, elasticity, and wear resistance can be tailored to improve performance under various operating conditions.

Applications of 14x22x5 Oil Seals

The 14x22x5 oil seal is utilized in a wide range of applications across different industries

. These include automotive, agricultural, aerospace, and industrial machinery. In automotive applications, oil seals play a vital role in engines, transmissions, and differentials, where they help ensure that lubricant stays within the system and contaminants do not enter. A leak in any of these systems can lead to severe mechanical issues, increased friction, and overheating, resulting in costly repairs.In machines used for agricultural purposes, such as tractors and harvesters, oil seals protect critical components like gearboxes and hydraulic systems. These environments are often harsh, with exposure to mud, water, and other particulates. Therefore, the reliability of oil seals is paramount to prevent failures and ensure smooth operation.

14x22x5 oil seal

Benefits of Proper Seal Use

Using the correct oil seal dimensions, such as 14x22x5, brings numerous benefits to mechanical systems. Firstly, it enhances efficiency by ensuring that lubricants remain where they are needed, thereby reducing wear on moving parts. This leads to extended equipment lifespan and decreased maintenance costs. Furthermore, effective sealing reduces energy consumption by preventing leaks that can lead to increased friction and overheating.

Secondly, the appropriate oil seal contributes to environmental sustainability. By preventing lubricant leaks, organizations can minimize their environmental impact and adhere to regulations regarding hazardous material spills. This not only protects the environment but also upholds a company’s reputation and commitment to sustainability.

Maintenance and Replacement

Regular maintenance and timely replacement of oil seals are essential practices to ensure continuous operation of machinery. Visual inspections can help identify signs of wear, cracking, or deformation in the oil seals. If leaks are detected, it is vital to replace the seals promptly to avoid further damage. The process of replacing an oil seal is relatively straightforward, but it requires a thorough understanding of the equipment and the proper procedures to ensure that the new seal is installed correctly.

Conclusion

The 14x22x5 oil seal is more than just a simple component; it is a crucial factor in the efficiency and longevity of mechanical systems. Understanding its specifications, applications, and benefits helps industries make informed decisions regarding the maintenance and replacement of these vital sealing solutions. By ensuring proper function and timely intervention, businesses can enjoy the advantages of increased reliability, lower operational costs, and a reduced environmental impact. When it comes to machinery, every detail matters, and the 14x22x5 oil seal exemplifies the importance of small components in achieving overall performance excellence.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories