फेब . 10, 2025 11:28 Back to list

wiper seals

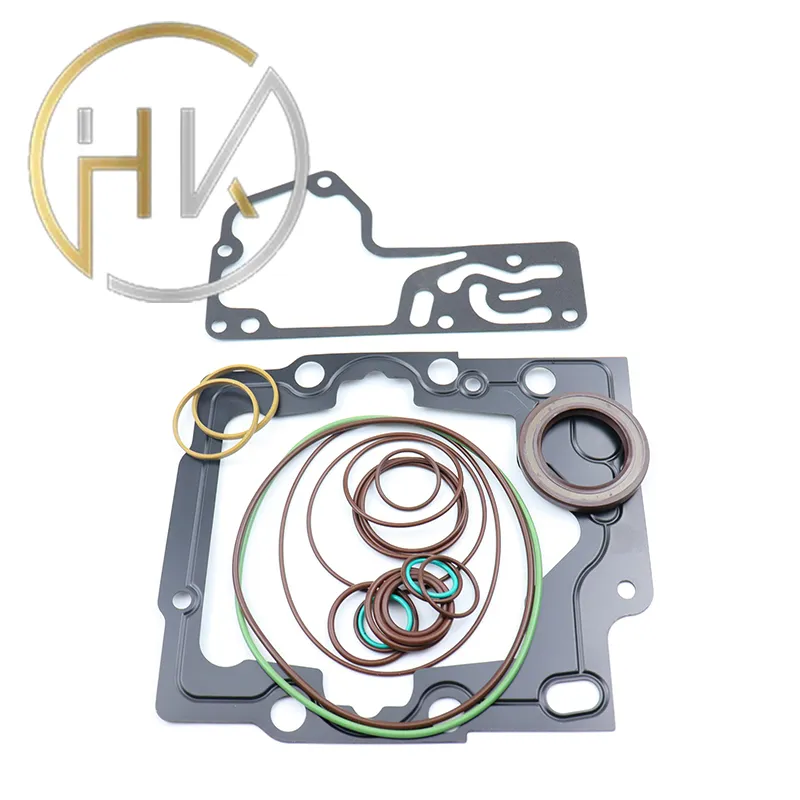

When selecting replacement seals, opt for high-quality materials that match the specifications required by your cylinder type and operating conditions. Seals made from durable, wear-resistant materials such as polyurethanes or synthetic rubbers are typically recommended for their longevity and robustness. An expert’s guidance in selecting the appropriate seals is invaluable to ensure compatibility and performance. Installation of the new seals must be executed with precision. Ensure that the seals are installed correctly, maintaining their original orientation as noted during disassembly. Tools such as seal installation picks and guides can assist in placing the seals without causing damage. Take care to avoid over-stretching or misaligning the seals, as improper installation can lead to malfunction or rapid deterioration. Once the seals are fitted, reassemble the cylinder carefully. Double-check all fastenings and connections to ensure everything is secure and aligned as intended. When the cylinder is reattached to the machinery, cautiously power up the system and test its operation. Check for leaks and ensure that full functionality has been restored. It’s advisable to run a few cycles to confirm the integrity of the seals and the efficiency of the hydraulic cylinder. Regular maintenance checks and timely seal replacements are part of a proactive strategy to maximize the lifespan and reliability of hydraulic systems. By investing in quality components and adhering to best practices during replacement, operators can significantly reduce unplanned downtime and optimize machine performance. Trusting experts in hydraulic systems to guide this process ensures the task is completed efficiently and effectively, reinforcing operational safety and procedural integrity. Documenting the replacement process and noting any issues observed can help in future maintenance and provide valuable insights for ongoing system improvements. Hydraulics are an indispensable part of many industries, and their upkeep is essential for continued productivity and safety. Through thorough preparation, adherence to technical guidance, and attention to detail during seal replacement, operators can sustain the optimal performance and longevity of hydraulic cylinders in their machinery systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories