नोभ . 22, 2024 21:09 Back to list

metric wiper seals

Understanding Metric Wiper Seals Key Features and Benefits

Wiper seals are critical components designed to prevent the leakage of fluids and contaminants in various mechanical systems. Among the different types available, metric wiper seals stand out due to their design specifications and compatibility with international standards. This article will delve into what metric wiper seals are, their applications, and the benefits they provide.

What Are Metric Wiper Seals?

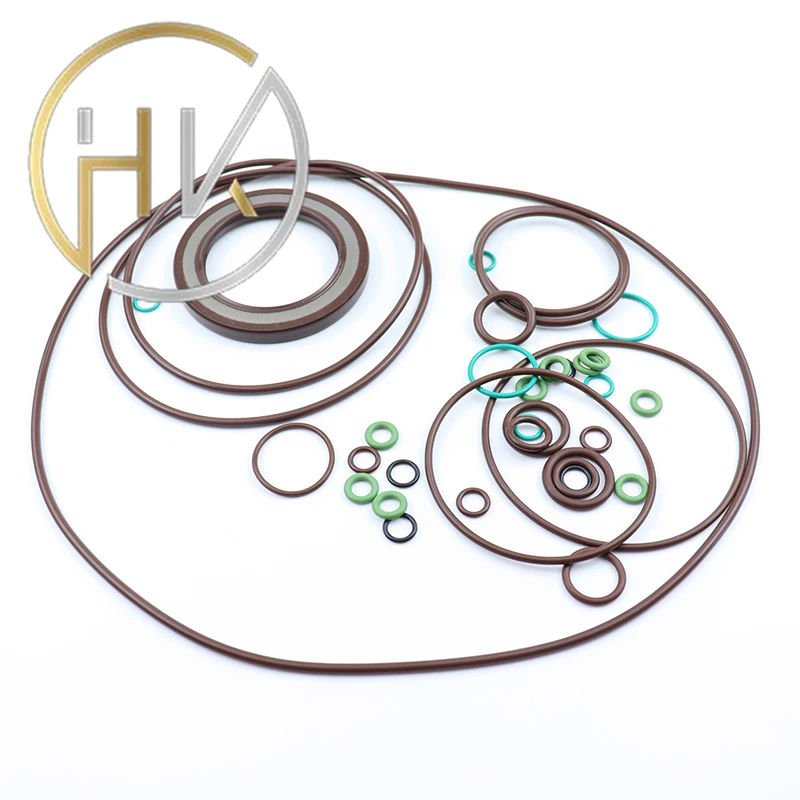

Metric wiper seals are specifically designed to fit metric-sized shafts and housings. They are used primarily in rotary applications where there is a risk of dirt, dust, or other contaminants entering the seal. These seals are typically constructed from durable materials like rubber or polymer, enabling them to withstand harsh environmental conditions while effectively performing their sealing functions.

The design of metric wiper seals often features a lip that wipes the surface clean as the shaft moves. This prevents contaminants from entering the bearing or hydraulic chamber, ensuring that the internal components remain clean and function optimally. The consideration of metrics in their design also means that these seals can fit seamlessly into systems manufactured globally, promoting versatility in applications.

Applications of Metric Wiper Seals

Metric wiper seals are widely used in various industries, including automotive, aerospace, manufacturing, and construction machinery. Some common applications include

1. Hydraulic Cylinders In hydraulic systems, wiper seals help prevent dirt and debris from entering the hydraulic cylinder, which can lead to system failure or reduced efficiency.

2. Pneumatic Systems In pneumatic applications, these seals ensure that air pressure is maintained while preventing external contaminants from interfering with system operations.

metric wiper seals

3. Linear Motion Systems Wiper seals are crucial in equipment that involves linear motion, such as conveyor systems and industrial automation machinery. They protect the internal components from wear and tear caused by contamination.

4. Automotive Applications These seals are used in various automotive components, including shock absorbers and steering mechanisms, helping to extend the lifespan of these critical parts.

Benefits of Metric Wiper Seals

1. Enhanced Protection The primary benefit of metric wiper seals is their ability to protect internal components from external contaminants. By acting as a barrier, they ensure that machinery operates smoothly and efficiently.

2. Extended Equipment Life By preventing contamination and reducing wear on moving parts, metric wiper seals contribute to increased equipment lifespan. This leads to lower maintenance costs and reduced downtimes for repairs and replacements.

3. Compatibility As they conform to international metric standards, these seals are compatible with a wide range of equipment and systems. This makes them a preferable choice for manufacturers operating globally.

4. Performance Efficiency By keeping the working environment clean, wiper seals enable systems to maintain their performance levels. This is particularly important in high-speed or high-precision applications where even minor contamination can lead to significant operational issues.

Conclusion

In conclusion, metric wiper seals play a vital role in ensuring the efficiency and longevity of various mechanical systems. Their design, engineered for optimal compatibility and performance, makes them indispensable in preventing contamination and protecting critical components. As industries continue to evolve and demand higher performance from machinery, the importance of reliable sealing solutions like metric wiper seals will only grow. For businesses looking to invest in equipment longevity and performance, understanding and utilizing high-quality wiper seals is paramount.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories