नोभ . 15, 2024 19:44 Back to list

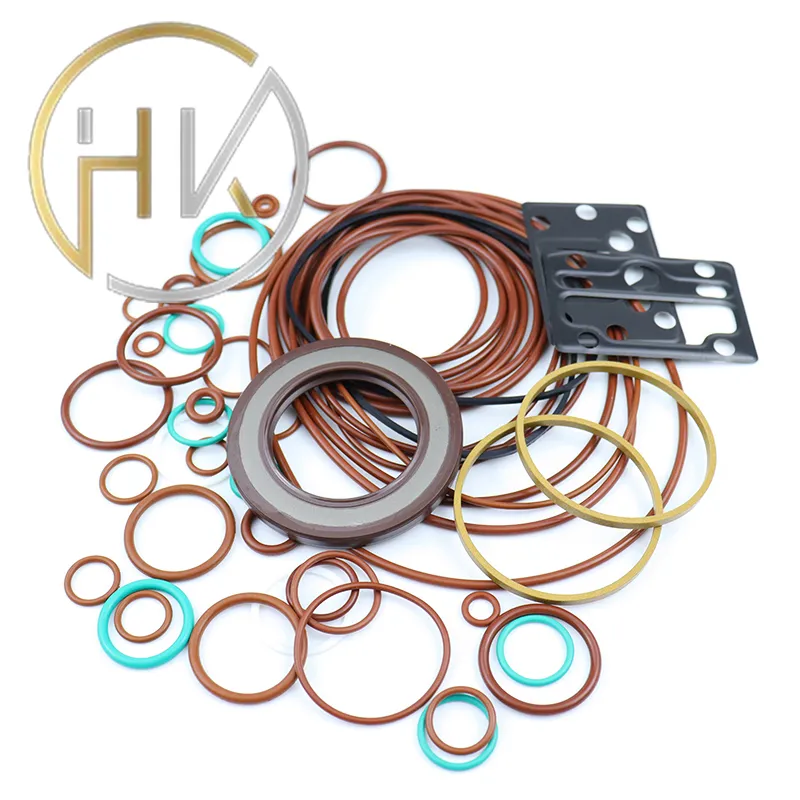

hydraulic seal repair

Understanding Hydraulic Seal Repair

Hydraulic systems are fundamental components in many industrial applications, serving to transmit power and control machinery with exceptional efficiency. However, like any mechanical system, hydraulic systems can encounter issues, particularly with seals. This article explores the importance of hydraulic seals, the common types of failures, and options for repair.

The Role of Hydraulic Seals

Hydraulic seals are essential components that prevent fluid leakage and maintain pressure within hydraulic systems. They are typically made of durable materials, such as rubber or plastics, designed to withstand high pressures and varying temperatures. Their primary functions include

1. Preventing Leakage Seals contain hydraulic fluid, ensuring that the system operates efficiently without losing pressure or fluid to the environment. 2. Protecting Components Seals keep contaminants out of the hydraulic system, prolonging the life of internal components such as pistons, cylinders, and valves. 3. Maintaining System Performance A well-functioning seal is crucial for the system's performance, influencing the speed, power output, and overall efficiency.

Common Causes of Seal Failure

Despite their robust design, hydraulic seals can fail due to several factors

1. Wear and Tear Continuous operation can cause seals to wear down, leading to leaks. This wear is often exacerbated by high temperatures and pressures. 2. Contamination Dirt, dust, and other contaminants can damage seals, leading to premature failure. Contaminated hydraulic fluid can also degrade seal material. 3. Improper Installation Incorrect installation can cause seals to misalign, leading to leaks and reducing their effectiveness. 4. Chemical Compatibility Some seal materials may not be compatible with certain hydraulic fluids. Using inappropriate fluids can cause the seals to swell or degrade.

Signs of Seal Failure

Identifying seal failure early can help prevent costly system downtime

. Common signs includehydraulic seal repair

- Visible Leaks Puddles of hydraulic fluid around hoses or joints. - Increased Noise Unusual sounds from hydraulic components can signal inadequate sealing. - Loss of Pressure Difficulty maintaining system pressure may indicate a compromised seal. - Contamination If contaminants are found in the hydraulic fluid, it may point to seal failure.

Repairing Hydraulic Seals

When seal failure occurs, repair options vary depending on the severity of the damage and the system design

1. Replacement The most common and often effective solution, seal replacement involves removing the damaged seal and installing a new one. This method ensures complete restoration of the system's integrity. 2. Seal Restoration Products In some cases, specialized products such as sealant or swelling agents can restore the seal's functionality temporarily. However, these are usually short-term solutions and do not address the underlying issues.

3. Professional Service For complex hydraulic systems, enlisting professional repair services might be necessary. Experts can diagnose issues accurately and provide tailored solutions that ensure long-term reliability.

Preventative Measures

To minimize the risk of seal failure, consider implementing preventative measures

- Regular Maintenance Conduct routine checks for leaks, wear, and contamination. - Use Quality Fluids Ensure that the hydraulic fluid used is compatible with the seal materials. - Avoid Contamination Implement filtration systems to keep the hydraulic fluid clean.

Conclusion

Hydraulic seal repair is a critical aspect of maintaining the efficiency and functionality of hydraulic systems. By understanding the causes of seal failure and recognizing the signs, operators can act swiftly to repair or replace seals as needed. Implementing preventive measures will also go a long way in ensuring that hydraulic systems remain reliable and efficient over time. Through proper maintenance and prompt attention to potential issues, businesses can minimize downtime and extend the life of their hydraulic equipment.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories