नोभ . 12, 2024 09:01 Back to list

hydraulic cylinder repair seal kit

Hydraulic Cylinder Repair Seal Kit Ensuring Peak Performance and Longevity

Hydraulic cylinders are critical components in various machinery and equipment, playing a pivotal role in converting hydraulic energy into mechanical work. These cylinders are widely used in industries such as construction, manufacturing, and transportation. However, like any mechanical device, they can wear out over time, leading to leaks and performance issues. One of the most effective ways to restore the functionality of a hydraulic cylinder is through the use of a hydraulic cylinder repair seal kit.

Understanding Hydraulic Cylinder Seals

Seals are essential in hydraulic cylinders as they prevent leakage of hydraulic fluid, ensuring that the cylinder can maintain pressure and function efficiently. Over time, seals can degrade due to factors such as heat, pressure, and the nature of the hydraulic fluid used. When seals become ineffective, it can lead to a loss of pressure, compromised performance, and ultimately, costly downtime.

What is a Hydraulic Cylinder Repair Seal Kit?

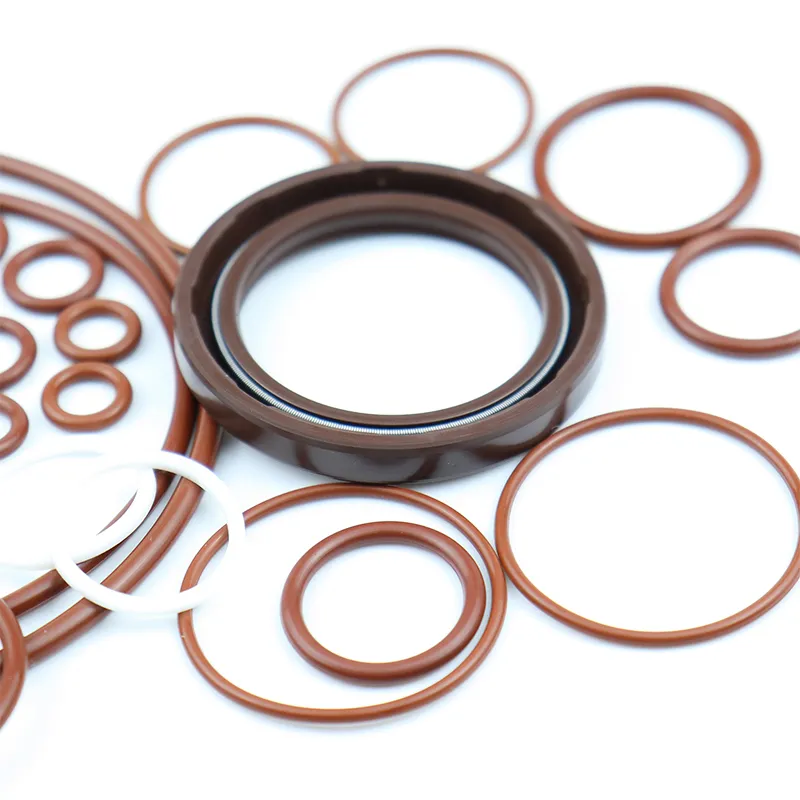

A hydraulic cylinder repair seal kit is a set of replacement seals and components designed to restore the integrity of a hydraulic cylinder. These kits typically include various seals, O-rings, backup rings, and sometimes additional components such as bushings or retaining rings. The specific contents of a seal kit may vary based on the application and type of hydraulic cylinder being repaired.

Benefits of Using a Repair Seal Kit

1. Cost-Effectiveness Repairing hydraulic cylinders with a seal kit is often far less expensive than replacing the entire cylinder. This makes it an attractive option for businesses looking to minimize maintenance costs while maximizing equipment uptime.

2. Improved Performance Replacing worn or damaged seals with new ones from a seal kit can significantly enhance the performance of a hydraulic cylinder. This can lead to improved efficiency in hydraulic systems, better operation of machinery, and overall enhanced productivity.

3. Extended Lifespan of Equipment Regular maintenance and repair using a seal kit can help extend the life of hydraulic cylinders and connected machinery. By proactively addressing leaks and wear, companies can avoid larger repair issues and expensive replacements down the line.

hydraulic cylinder repair seal kit

4. Ease of Use Most hydraulic cylinder repair seal kits come with detailed instructions for installation, making it easier for technicians to perform repairs without requiring extensive specialized training. This enhances the overall efficiency of maintenance operations.

How to Choose the Right Repair Seal Kit

Selecting the correct hydraulic cylinder repair seal kit is crucial for ensuring compatibility and successful repairs. Here are some key factors to consider

1. Cylinder Specifications Before purchasing a seal kit, it's essential to know the specifications of the hydraulic cylinder, including its make, model, and size. This information ensures that the kit is compatible and contains all necessary components.

2. Seal Material The type of seal material can affect the performance and longevity of the seals. Common materials include nitrile rubber (Buna-N), viton, and polyurethane, each suitable for different types of hydraulic fluids and operating conditions.

3. Application Consider the specific application of the hydraulic cylinder. Is it used in high-pressure environments? Is it exposed to extreme temperatures? Different operating conditions may require different seal properties and designs.

4. Supplier Reputation It's advisable to purchase repair seal kits from reputable suppliers or manufacturers known for quality products. This ensures that the seals are made of high-quality materials and that they meet industry standards.

Conclusion

A hydraulic cylinder repair seal kit is an invaluable tool for maintaining the efficiency and functionality of hydraulic systems. By addressing seal wear and leaks proactively, businesses can save on costs, enhance machinery performance, and prolong the lifespan of their equipment. Proper care, maintenance, and timely repairs using a seal kit can make a significant difference in hydraulic operation, ensuring that machines continue to run smoothly and efficiently. As such, investing in a quality hydraulic cylinder repair seal kit is a smart choice for any industry reliant on hydraulic technology.

-

Understanding Oil Seals and Their Role in Machinery Efficiency

NewsApr.08,2025

-

The Importance of Seals in Agricultural and Hydraulic Systems

NewsApr.08,2025

-

Essential Guide to Seal Kits for Efficient Machinery Maintenance

NewsApr.08,2025

-

Choosing the Right TCV Oil Seal for Your Machinery

NewsApr.08,2025

-

Choosing the Right Hydraulic Oil Seals for Reliable Performance

NewsApr.08,2025

-

A Comprehensive Guide to Oil Seals and Their Applications

NewsApr.08,2025

-

The Importance of High-Quality Oil Seals in Industrial Applications

NewsMar.26,2025

Products categories