फेब . 14, 2025 20:30 Back to list

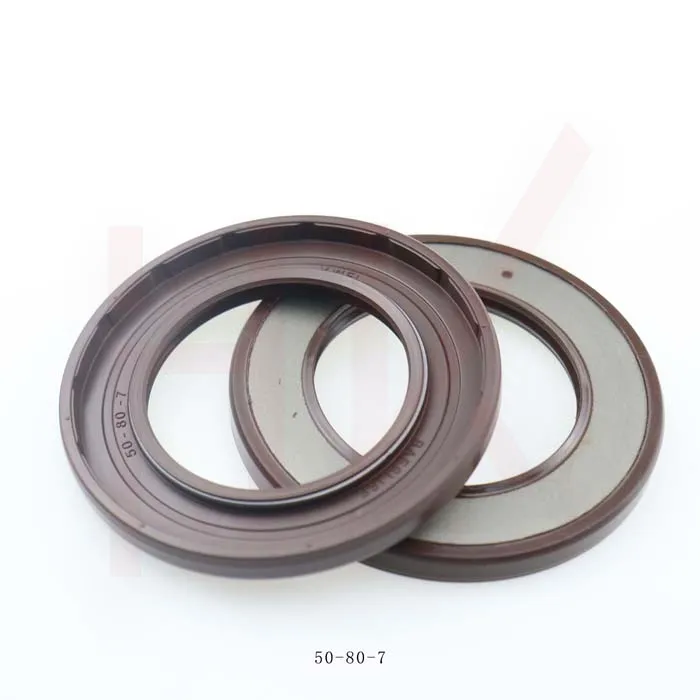

Standard Wheel Hub Oil Seal For Agricultural Machinery

Trustworthiness is engendered through transparent communication and reliable performance histories. Manufacturers of custom oil seals provide meticulous documentation, including technical specifications, material safety data sheets, and performance test results, ensuring that clients are well-informed about their purchase. This transparency fosters a relationship of trust, as customers feel confident in the products they are integrating into their systems. Reliability is further enhanced by offering warranties and post-sale support, reinforcing the manufacturer's commitment to quality and customer satisfaction. Custom made oil seals are not merely components; they are critical enablers of operational excellence across numerous industries. These seals uphold the integrity of mechanical systems, prevent costly downtimes, and protect investments in machinery. As industries continue to evolve and demand even more sophisticated solutions, the expertise, authority, and trust that custom oil seal manufacturers deliver are indispensable in meeting these challenges head-on. Therefore, when choosing a custom oil seal provider, it's imperative to consider not just the immediate needs but also the long-term reliability and support. This holistic approach ensures that the sealing solutions provided will effectively contribute to the efficiency and sustainability of processes, solidifying a partnership built on trust and shared success. As these components quietly go about their essential tasks, they highlight the profound impact of choosing the right sealing solution, ultimately driving industries forward with precision and reliability.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories