Dec . 09, 2024 17:31 Back to list

Front Hub Seal Replacement Guide for Optimal Performance and Longevity

Understanding Front Hub Seals Their Importance and Functionality

Front hub seals are critical components in the anatomy of a vehicle's wheel assembly. Although often overlooked by casual drivers, they play a significant role in ensuring the longevity and efficient operation of a vehicle. By securing the axle and preventing contaminants from entering the hub, front hub seals contribute towards improved performance and reliability of the vehicle.

The Role of Front Hub Seals

At their core, front hub seals are designed to maintain lubricant integrity within the hub assembly. These seals function primarily to keep grease or oil contained within the hub while simultaneously barring dirt, dust, water, and other impurities from infiltrating this essential area. This is especially important because any contamination can lead to accelerated wear and tear of the bearings and other critical wheel components.

In a nutshell, the main functions of front hub seals include

1. Lubrication Retention By keeping lubricants such as grease within the hub, the seals ensure that the bearings are well-lubricated, reducing friction and heat generation during operation.

2. Contaminant Exclusion The seals act as barriers against external debris and moisture, safeguarding the hub assembly from potential damages that can be caused by foreign particles.

3. Pressure Management In certain instances, as the vehicle operates, changes in temperature can cause air within the hub to expand, creating pressure differences. Properly functioning seals help manage this pressure to prevent leaks.

Types of Front Hub Seals

There are various types of front hub seals used depending on the vehicle's design and intended use. Common types include

- Rubber Seals These are often used in standard vehicle applications thanks to their flexibility and durability. Rubber seals can provide an effective barrier against moisture and dirt while maintaining a good seal under varying temperatures.

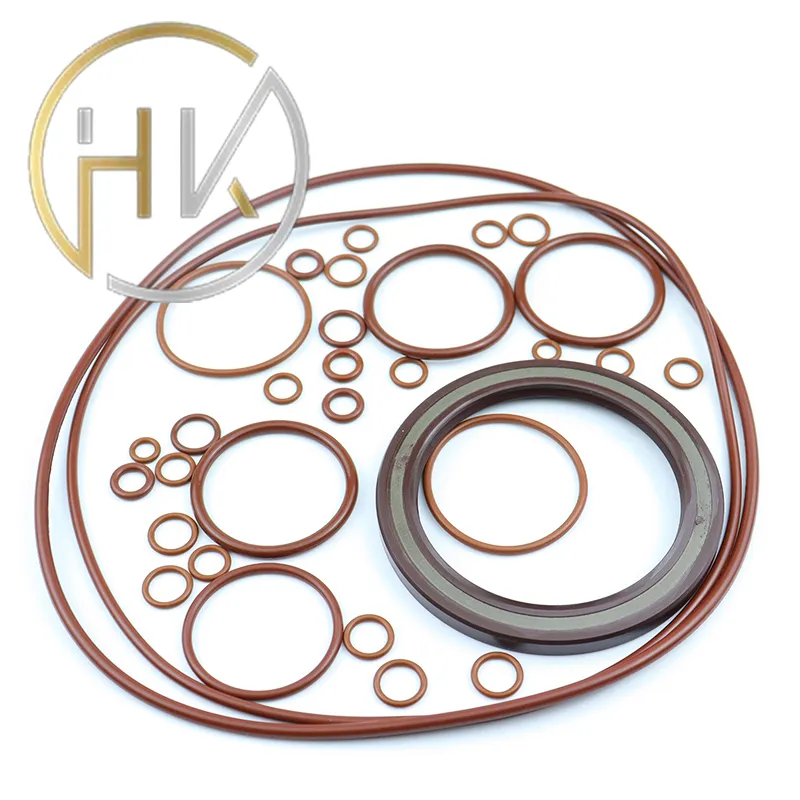

front hub seal

- Metal Shields Some hubs utilize metal shields that are more rigid than rubber seals. These shields can provide superior protection against debris, but they may not retain lubrication as effectively as rubber options.

- Labyrinth Seals These employ a more complex design with a series of grooves and paths that make it difficult for contaminants to reach the hub. Although they can be more expensive, labyrinth seals are noted for their effectiveness in challenging environments.

Common Issues and Maintenance

Like any mechanical component, front hub seals can degrade over time. Factors such as exposure to harsh environmental conditions, improper installation, or prolonged wear can lead to seal failure. A common sign of failing hub seals is grease leakage or discoloration on the wheel rim, indicating lubricant loss and potential contamination.

To prevent issues, regular maintenance of the wheel assembly is essential. This includes

- Visual Inspections Routinely checking the hub seals for signs of wear, cracks, or leaks can help identify problems early before they escalate into more serious issues.

- Lubrication Checks Ensuring that the lubricant levels are adequate and replacing it as necessary helps maintain effective sealing performance.

- Timely Replacements If a seal is found to be compromised, replacing it promptly can prevent further damage to the hub assembly and associated components.

Conclusion

Front hub seals may be small components in the grand scheme of a vehicle’s functionality, but their importance cannot be overstated. They serve as the first line of defense against contamination, ensuring that the wheel assembly operates smoothly and efficiently. Regular inspection and maintenance of these seals can greatly extend the lifespan of the hub assembly, promote safety on the road, and enhance overall vehicle performance. Understanding the role and care of front hub seals is essential for anyone who values their vehicle’s reliability and longevity.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories