Nov . 20, 2024 17:12 Back to list

shaft dust seal

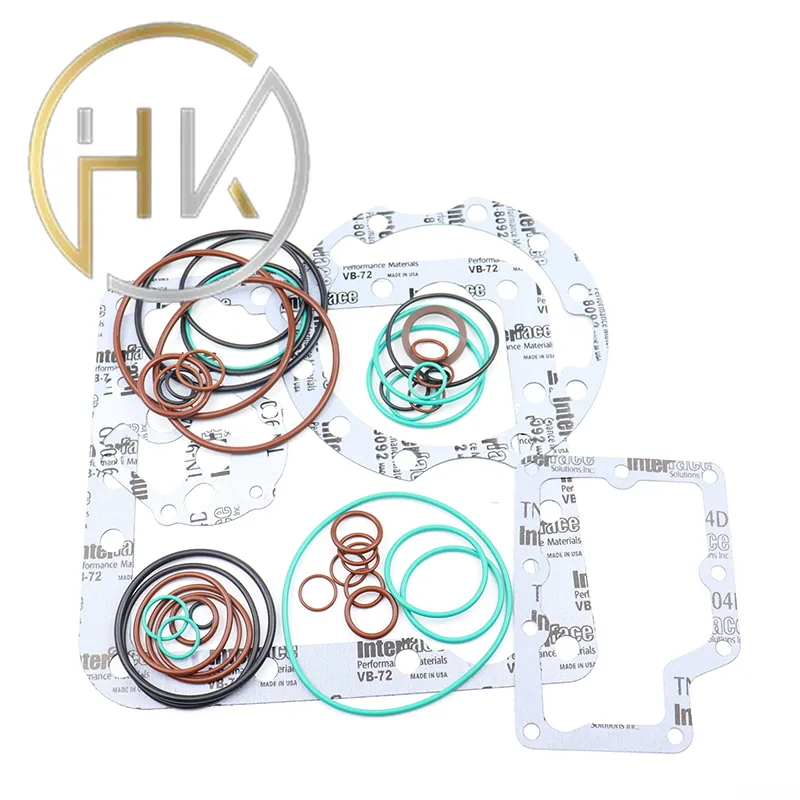

Understanding Shaft Dust Seals Importance and Applications

In industrial machinery, the term “shaft dust seal” refers to a critical component designed to protect rotating shafts from contaminants like dust, dirt, and moisture. These seals play a vital role in maintaining the efficiency and longevity of equipment, particularly in applications that operate in harsh environments. By creating a barrier between external elements and the moving parts of machinery, shaft dust seals serve to enhance the overall performance and reliability of various systems, including motors, pumps, and gearboxes.

The Importance of Shaft Dust Seals

Shaft dust seals are essential for several reasons. First and foremost, they prevent the ingress of contaminants that can lead to wear, corrosion, and damage to bearings and other internal components. When dust and dirt enter a rotating assembly, they can create friction, generating heat and accelerating wear. This not only shortens the service life of the machine but can also lead to unplanned downtime and costly repairs.

Moreover, moisture intrusion can pose an even greater threat, particularly in applications involving hydraulic systems or electrical components. Water can cause rust and promote the growth of mold and mildew, leading to system failures. Therefore, implementing effective dust seals can significantly reduce maintenance costs and repair frequency over time.

Types of Shaft Dust Seals

Shaft dust seals come in various designs tailored to specific applications and operating environments. The most common types include

1. Lip Seals These seals feature a flexible lip that makes direct contact with the shaft. The design allows for good containment of lubricants while preventing dirt and dust infiltration. They are ideal for applications with moderate rotation speeds.

2. Mechanical Seals Primarily used in applications involving fluids, mechanical seals prevent leaks between stationary and rotating components. Although more complex than lip seals, they offer superior protection against both liquid and particulate ingress.

3. V-Ring Seals V-rings are versatile and simple in design. They are made from elastomers and are mounted on a shaft, providing a sealing effect against dust and moisture while allowing flexibility in radial and axial movements.

shaft dust seal

4. Face Seals These are used in more specialized applications, generally where both pressure and vacuum exist. The sealing surfaces of face seals are flat and can be made of advanced materials to withstand extreme conditions.

Applications of Shaft Dust Seals

Shaft dust seals are used in numerous industries, each with unique operational demands. They can be found in

- Manufacturing In factories, rotating machinery like conveyor systems and mixers benefit from dust seals to ensure continued operation.

- Automotive Vehicles utilize shaft seals in engines and transmissions to keep lubricants contained while protecting against external contaminants.

- Aerospace Here, the need for reliability is paramount; seals protect critical rotating components from dust and moisture in addition to maintaining optimal lubrication.

- Agricultural Equipment Tractors and harvesters operate in dusty and muddy environments, making dust seals vital in prolonging the equipment's life.

Conclusion

In summary, shaft dust seals are an indispensable component in the design and functioning of various machinery. By preventing the entry of dust, dirt, and moisture, these seals play a crucial role in protecting sensitive internal components, thereby enhancing equipment longevity and operational efficiency. With advancements in materials and manufacturing techniques, modern seals can withstand more challenging conditions than ever before. Understanding the types of shaft dust seals and their applications can empower engineers and technicians to make informed decisions in the design and maintenance of reliable machinery.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories