Feb . 17, 2025 13:38 Back to list

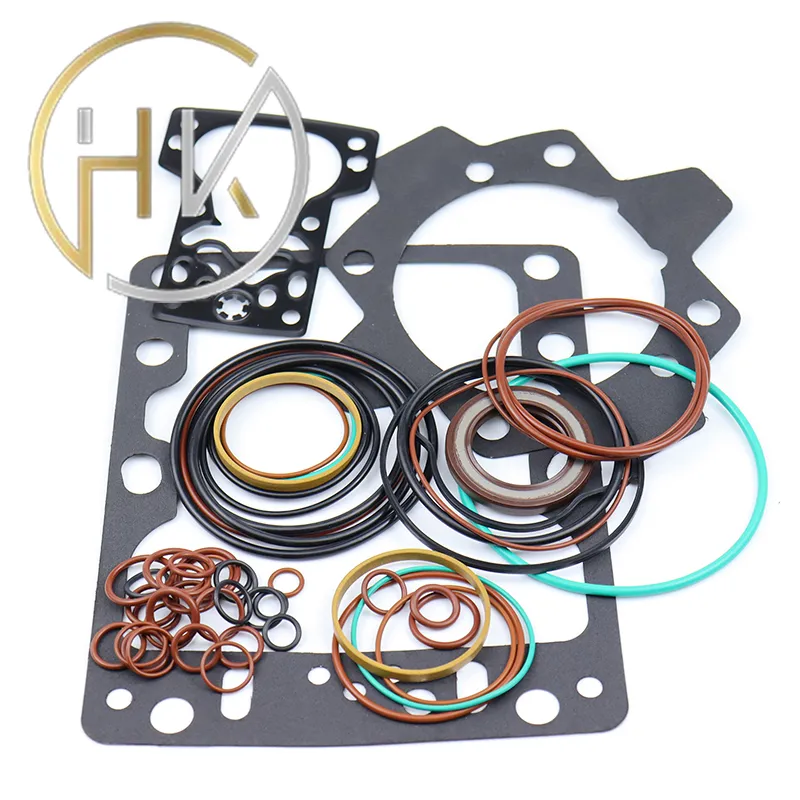

Standard Hydraulic DKB Type Dustproof Wiper Oil Seal

Trustworthiness in this domain is depicted by brands that not only provide excellent products but also offer comprehensive customer support and clear warranty information. Such brands typically have transparent communication, helping customers make informed decisions about their purchases. They often provide detailed instructions for seal installation and maintenance tips, further instilling confidence in their expertise. Case studies reveal the impact of using the correct seal kit on machinery efficiency and lifespan. For instance, in the agricultural sector, a farming enterprise reported a notable decrease in downtime after switching to a high-density polyurethane seal kit for their hydraulic motors used in tractors and harvesters. The new seal kits mitigated oil leaks, maintained hydraulic pressure consistency, and ultimately improved equipment reliability. This real-world experience highlights the critical role of selecting superior quality seal kits and punctuates their value in maximizing equipment uptime and productivity. In conclusion, investing in a superior seal kit for hydraulic motors is more than just a maintenance task; it’s a strategic decision that embraces technical expertise, manufacturing authority, and brand trust. A well-chosen seal kit not only fortifies the hydraulic motor against potential failures but also ensures that machinery operates at its full potential, safeguarding business operations across various industries. As sustainability and efficiency become ever more critical in industrial applications, aligning with trusted providers of hydraulic seal kits is indispensable for long-term success and operational excellence.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories