Aug . 29, 2024 17:51 Back to list

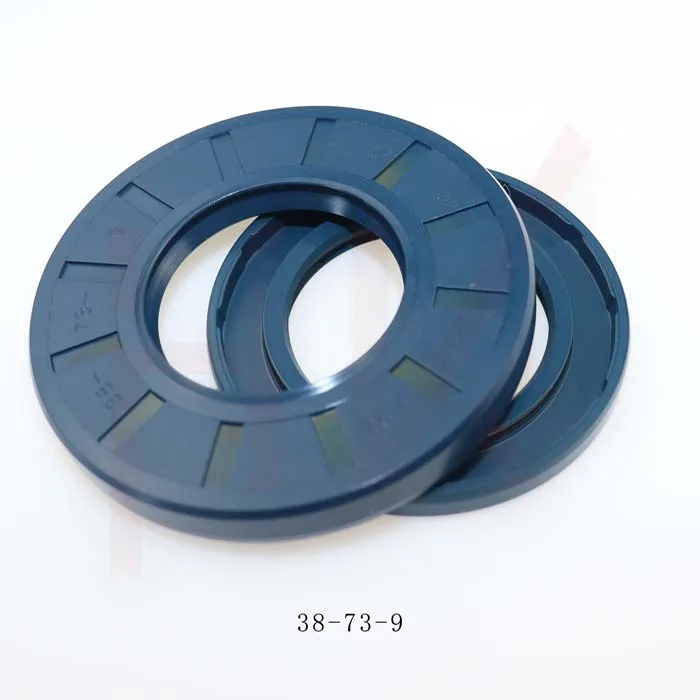

Metric Rod Wiper - Precision Cleaning Solutions for Your Equipment

Understanding the Metric Rod Wiper Importance and Applications

In the world of engineering and manufacturing, precise measurements and dry surfaces are crucial. One component that plays a vital role in achieving these standards is the metric rod wiper. This essential device is engineered to maintain cleanliness and functionality in various systems, particularly hydraulic and pneumatic applications.

A metric rod wiper is designed to fit metric-sized rods, providing a sealing solution that prevents dust, dirt, and other contaminants from entering critical components such as hydraulic cylinders and pneumatic cylinders

. The wiper is strategically placed at the rod's entry point, ensuring that any particles that may have settled on the rod's surface are wiped away before the rod retracts into the housing. This functionality is vital for maintaining the longevity and efficiency of these systems.The construction of a metric rod wiper typically involves durable materials that can withstand extreme conditions. Common materials include polyurethane, rubber, and other resistant compounds that provide excellent abrasion resistance and flexibility. The design of the wiper and its lip profile is also crucial, as it determines how effectively it will seal and wipe the rod while accommodating variations in rod dimensions.

metric rod wiper

In various industrial applications, the significance of having a reliable rod wiper cannot be understated. For instance, in the automotive industry, hydraulic systems rely heavily on rod wipers to ensure that hydraulic cylinders operate smoothly without any interference from contamination. Similarly, in construction and manufacturing equipment, rod wipers contribute to the overall performance and reliability of machinery, preventing costly downtime caused by wear and tear.

Moreover, the metric rod wiper contributes to safety in industrial environments. By keeping contaminants at bay, it reduces the risk of mechanical failures that could lead to hazardous situations. Regular maintenance and timely replacements of these wipers are essential to maintaining operational efficiency and safety standards.

In conclusion, the metric rod wiper might seem like a small component, but its role in various applications is significant. From enhancing machinery longevity to ensuring safety, the importance of this device cannot be overlooked. As industries continue to evolve, advancements in rod wiper designs and materials will play a crucial part in improving functionality and performance in engineering applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories