Feb . 06, 2025 04:11 Back to list

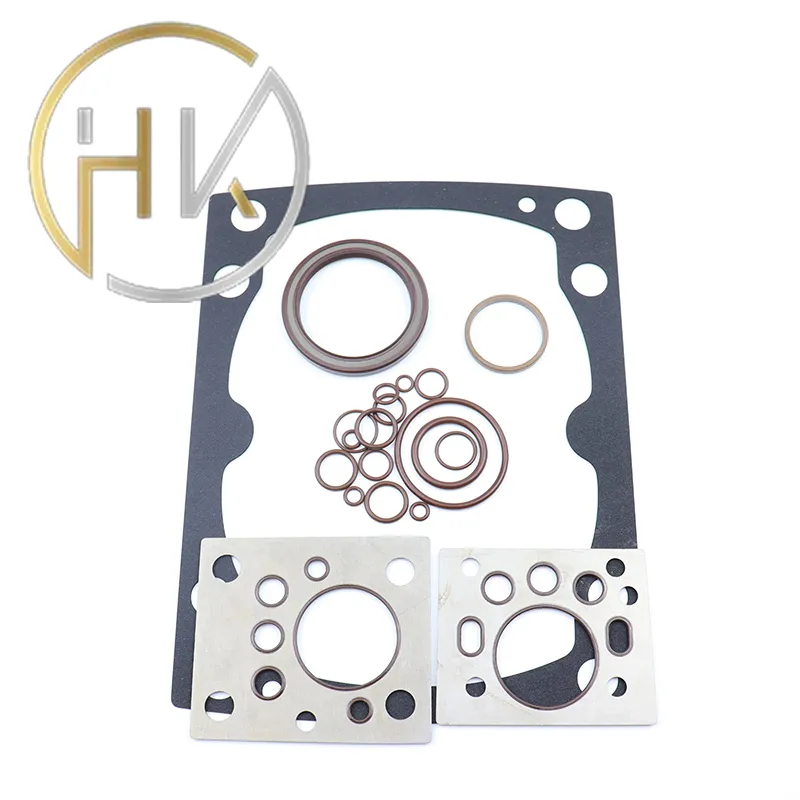

oil seal tcv

Trustworthiness of the hydraulic oil seal kit is guaranteed through rigorous testing and quality assurance standards. Reputable manufacturers provide kits that come with certifications and standards compliance, ensuring that the products can withstand harsh operational conditions and deliver consistent performance. It’s important to source kits from credible suppliers who offer warranties and customer support, safeguarding your investment and reinforcing trust in the product’s reliability. Real-world experience also plays a pivotal role in enhancing the trustworthiness and functionality of hydraulic oil seal kits. Operators and engineers often possess experiential insights, having worked hands-on with these components in various settings. Feedback and real-life testing results contribute immensely to the design improvements and functionality of sealing kits, ensuring they align well with the practical challenges encountered in the field. Therefore, choosing a hydraulic oil seal kit also means tapping into a wealth of accumulated knowledge and field-tested expertise. Overall, effective implementation of hydraulic oil seal kits requires a blend of technical understanding, thorough product knowledge, and trustworthy sourcing. By choosing the right kit, industrial operations can expect reduced maintenance costs, prolonged equipment life, and improved system efficiency. Innovative sealing solutions are continuously evolving, driven by both technological advancements and insights from industry professionals who have dedicated themselves to creating systems that meet the demands of modern hydraulic applications. Investing in top-quality hydraulic oil seal kits is a decision that echoes effective maintenance and operational excellence in the hydraulic systems landscape, ultimately empowering industries to reach new heights of performance and reliability.

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

-

Graphene-Enhanced Oil Seals: Revolutionizing High-Pressure Oil Sealing

NewsJun.06,2025

-

Future of Hydraulic Sealing: Advanced Intelligent TCN Oil Seals

NewsJun.06,2025

-

Don’t Let a Broken TCV Oil Seal Ruin Your Day

NewsJun.06,2025

-

Bio-Inspired Dust Seals for Better Sealing Performance

NewsJun.06,2025

-

Biodegradable and Sustainable Hydraulic Seal Materials

NewsJun.06,2025

-

Top Oil Seal Solutions for Your Industrial Needs

NewsMay.22,2025

Products categories